Tray-free operation mechanism for brick stack packaging

A technology of brick stacks and pallets, which is applied in the field of pallet-free operation mechanism, can solve the problems of increased pallet manufacturing cost and later maintenance cost, poor pallet operation stability, complicated manufacturing process, etc., and achieves reduced manufacturing and maintenance costs, easy maintenance and installation, and structural Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

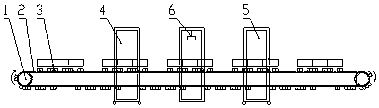

[0011] Such as figure 1 As shown, the present invention provides a pallet-free operating mechanism for brick stack packaging, including a frame 1, an endless chain 2, a stacking assembly 3, a packing assembly 4 before stacking, a packing assembly 5 after stacking, and a stacking assembly The component 6 is characterized in that: the circulating chain 2 performs a step-by-step circular movement on the frame 1, and the stacking component 3 is installed on the circulating chain 2 according to a certain distance, and the stacking component 3 is composed of several profiles with lateral flexibility It is formed by connection and combination, which can be combined according to different brick types and stacking types. The space between adjacent profiles is convenient for packing belts to pass through. The packing assembly 4 before the stacking, the packing assembly 5 after the stacking, and the stacking assembly 6 are installed on the frame 1 at an appropriate distance and independe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com