Finished brick grouping device and method

A technology of finished products and marshalling lines, applied in packaging, packaging machines, building materials packaging, etc., can solve the problems of different rows of pressed bricks, difficulty in automatic packaging, etc., and achieve the effect of reducing the dependence on equipment models and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0033] The orientations involved in this manual are all based on the orientations of the marshalling device and marshalling method of the finished bricks of the present invention when they are in normal operation, and do not limit their orientations during storage and transportation. They only represent relative positional relationships, not absolute positional relationships. .

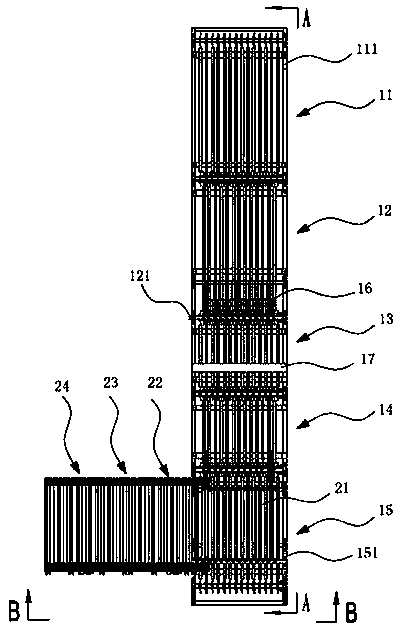

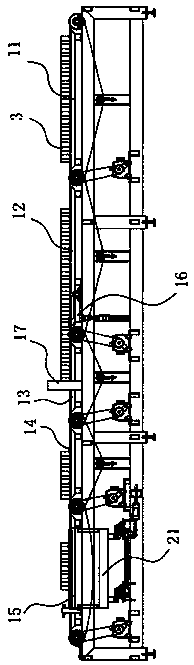

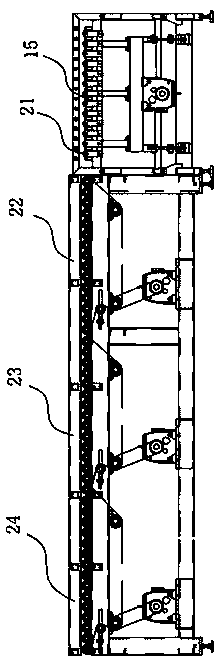

[0034] Such as figure 1 As shown, the marshalling device for finished bricks, its main body includes a chain marshalling line 1 and a roller marshalling line 2, the chain marshalling line 1 is used to determine the number of rows of the square matrix of bricks, and the roller marshalling line 2 is used to determine the number of bricks. The number of columns of the square matrix.

[0035] Such as figure 1 and figure 2 Commonly shown, each station of the chain marshalling line 1 is driven by a motor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com