Packaging unit and packaging method of aerated concrete block

A kind of technology of aerated concrete and packaging unit, which is applied in the directions of building materials packaging, transportation and packaging, and the type of packaged items. It can solve the mismatch between packaging production and brick production line, difficulty in guaranteeing recovery rate and intact rate, and backward packaging technology, etc. problem, achieve the effect of reducing loading and unloading workload, simple structure, and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

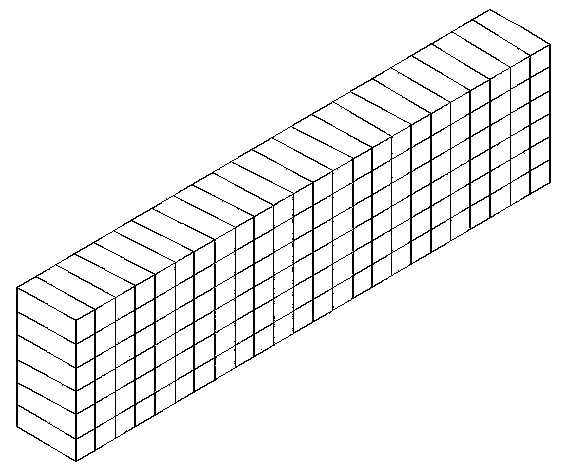

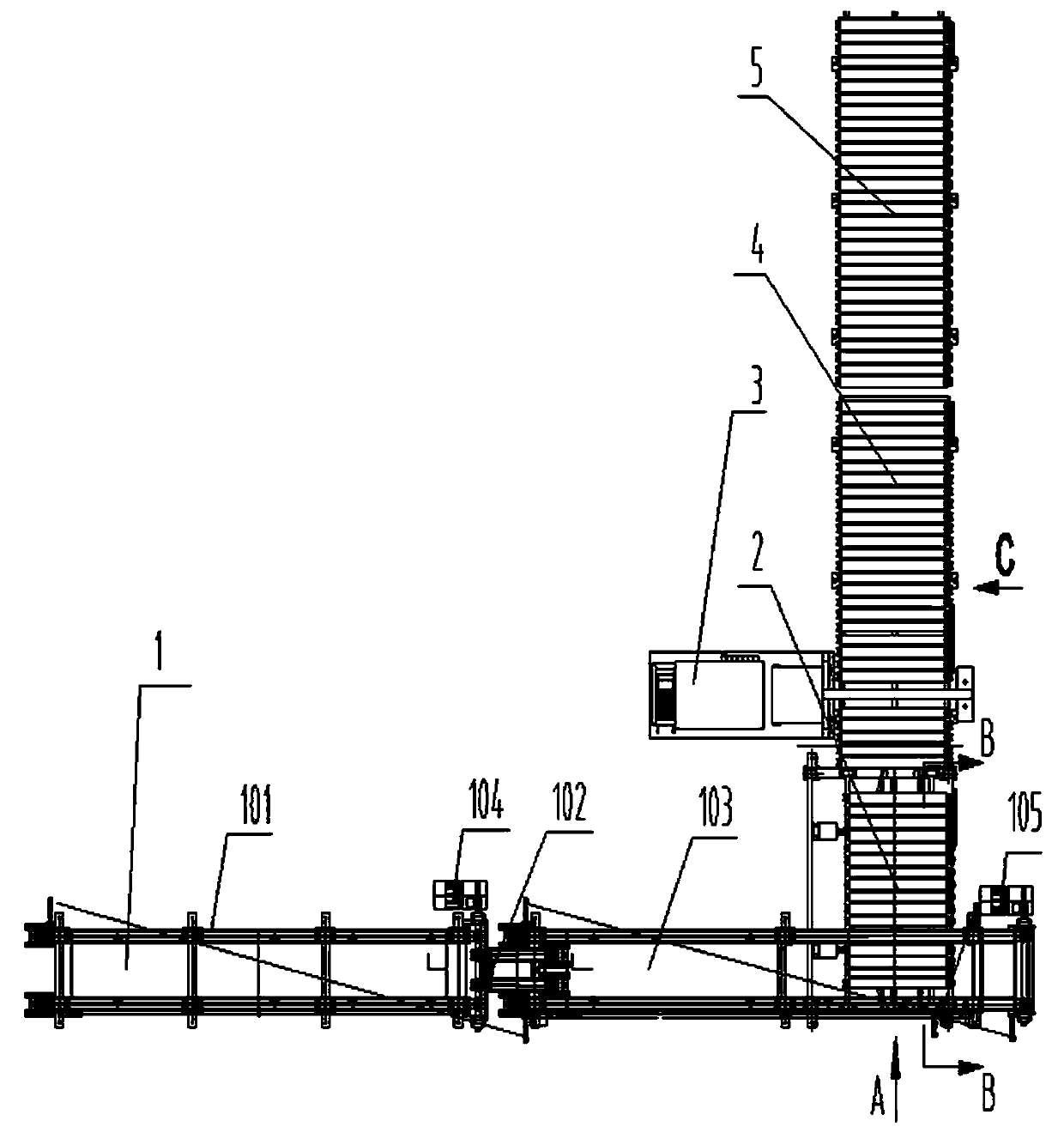

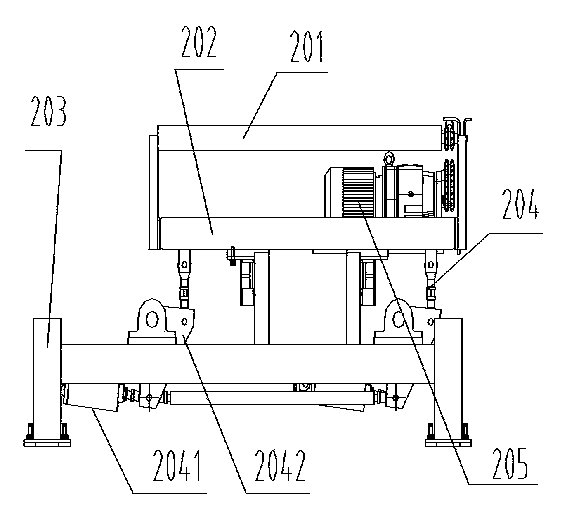

[0027] Such as Figure 3 to Figure 8 The packaging unit for aerated concrete blocks shown includes a conveying device 1, a lifting roller table 2 for stacking and steering, a packing roller table 4 connected with the lifting roller table 2, and a packing roller table 4 arranged on the packing roller table 4 correspondingly. The binding machine 3 in the position, the conveying device 1 is provided with two conveyor belts arranged in parallel at intervals, and the lifting roller table 2 is arranged at the end of the conveying device 1, including a row of lifting rollers that are parallel to the conveyor belt and can be lifted up and down at the same time. Idler rollers 201, some of which are located between the two conveyor belts, are used to hold up part of the aerated concrete block stacks erected between the two conveyor belts to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com