Ceramic tile flexible container bundling table

A technology for container packaging and ceramic tiles, which is applied to the parts of binding machinery, building material packaging, transportation and packaging, etc., can solve the problems of not having multiple brick package bindings, major safety accidents, and low warehouse utilization, and achieve a reduction in relative Effects of travel, enhanced firmness, and utilization of warehouse space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

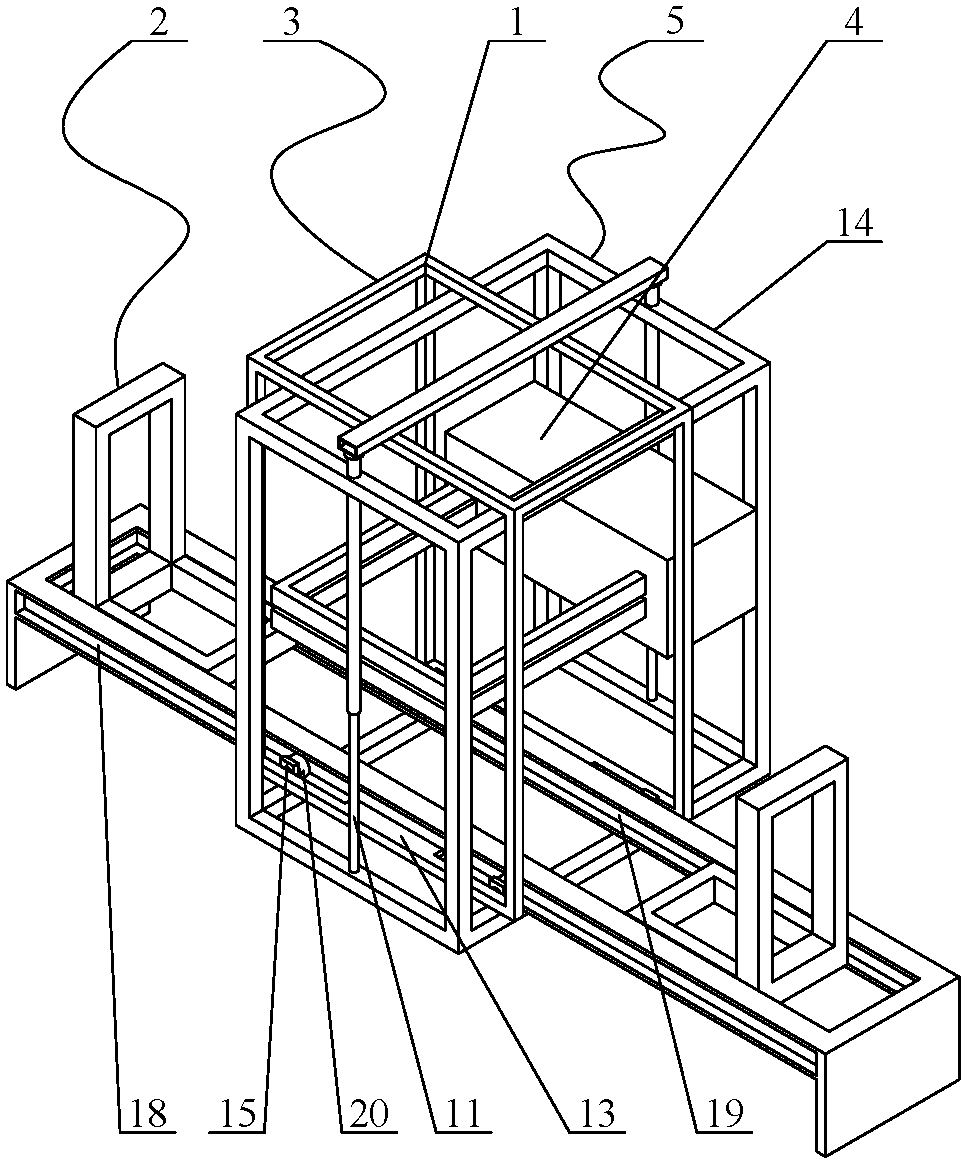

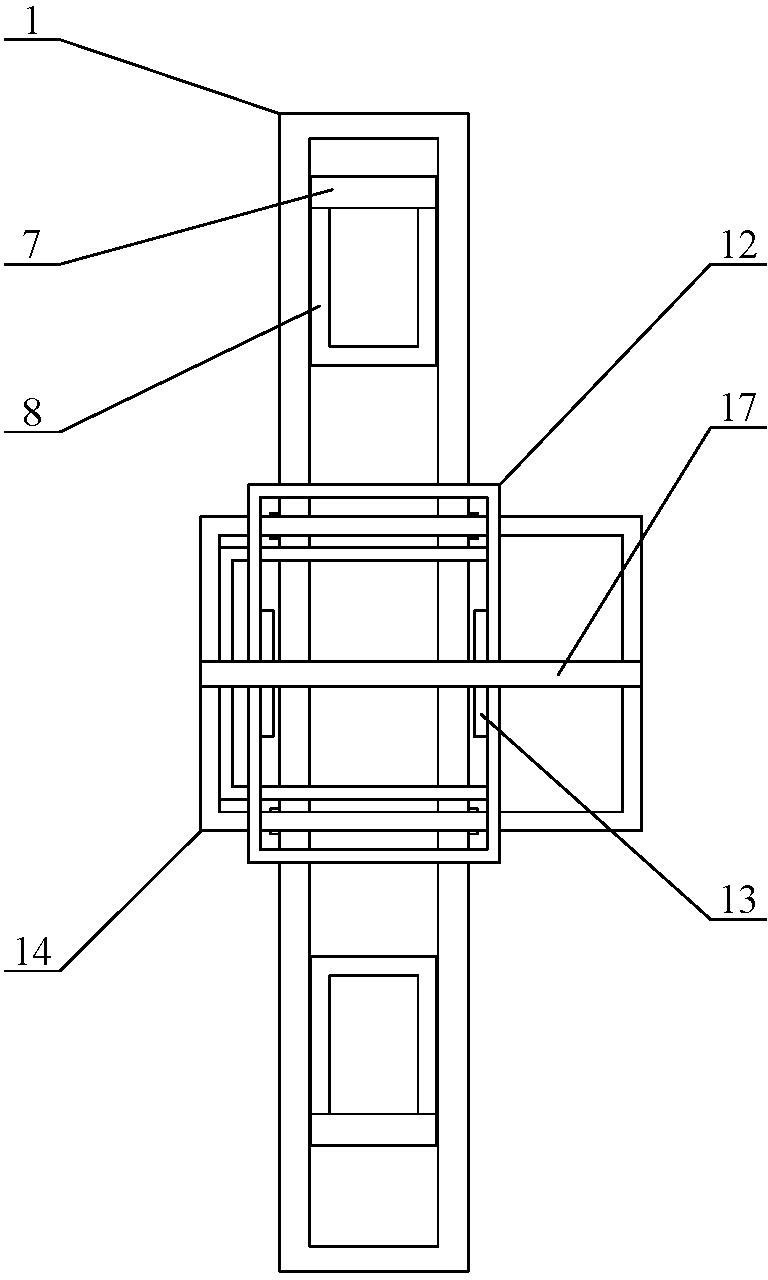

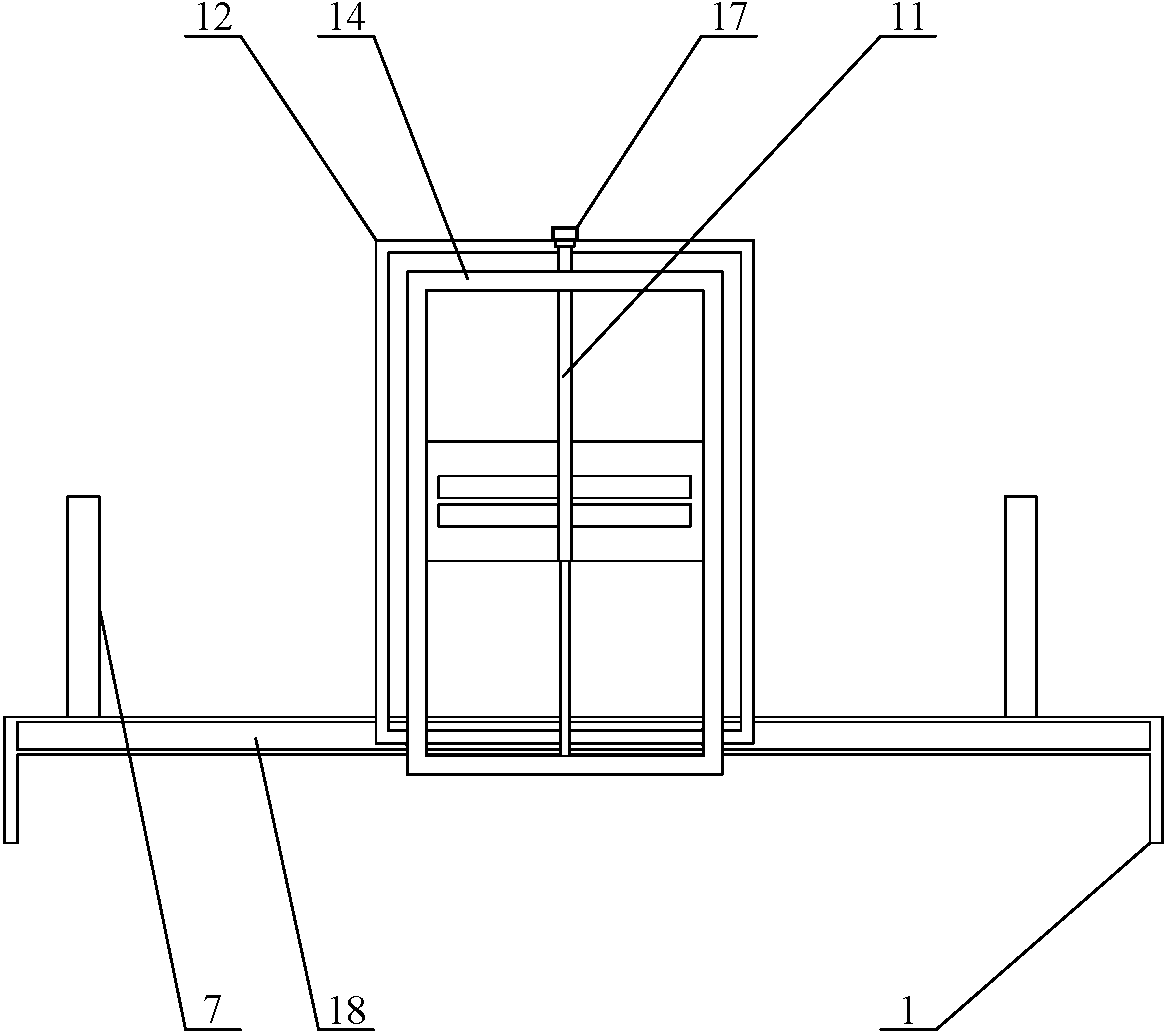

[0031] Such as figure 1 , 2 , 3, 4, and 5, a tile container binding platform, the frame 1 is provided with an outer guide rail 18 and an inner guide rail 19; the frame 1 is provided with a pair of clamping devices 2 . The clamping device 2 includes a clamping plate 7, a clamping platform 8, a rack 9 and a gear 10; the left and right sides of the clamping platform 8 are provided with guide wheels 16, and the guide wheels 16 are cooperatingly arranged on the inner guide rail 19; The clamping plate 7 is vertically fixed, and the surface of the clamping plate 7 is perpendicular to its moving direction; a motor driving device 6 and a gear 10 are arranged at the bottom of one of the clamping tables 8, and the gear 10 is connected with the motor driving device 6; one end of the rack 9 is connected to the other One clamping table 8 is connected, and the other end meshes with the gear 10. When the motor drive device 6 starts, the gear 10 rotates to drive the rack 9 to move, so that th...

Embodiment 2

[0041] Compared with Embodiment 1, the clamping device 2 in this embodiment can be driven by a hydraulic cylinder, and a hydraulic cylinder is installed under one of the clamping tables. The push rod of the hydraulic cylinder is connected with another hydraulic cylinder to form a series connection, and the other clamp The holder is connected with the push rod of another hydraulic cylinder.

[0042] The corresponding working principle and working process are as follows:

[0043] When the tile container is hoisted to the binding table, the crane will place several tile containers on one of the clamping platforms 8, and the tile container is against the clamping plate 7, and the hydraulic cylinder works at this time , the push rod is recovered in the cylinder, so that the two clamping plates clamp the tile container bag. Other processes are as described in Embodiment 1, and will not be repeated here.

Embodiment 3

[0045] Compared with Embodiment 1, the translation device 5 in this embodiment can be driven by a chain. Chain is installed on frame 1 outside, and frame 1 one end is equipped with motor and sprocket wheel, and sprocket wheel cooperates and is installed on the motor rotating shaft, and chain is engaged with sprocket wheel, and mobile frame 14 is fixed with a certain joint of chain.

[0046] The corresponding working principle and working process are as follows:

[0047] After the clamping device 2 clamps the tile container, the motor on the frame 1 drives the gear to rotate, and the gear drives the chain to run, and the mobile frame 14 moves to the position of the tile container along the outer guide rail 18 under the traction of the chain. Other processes are as described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com