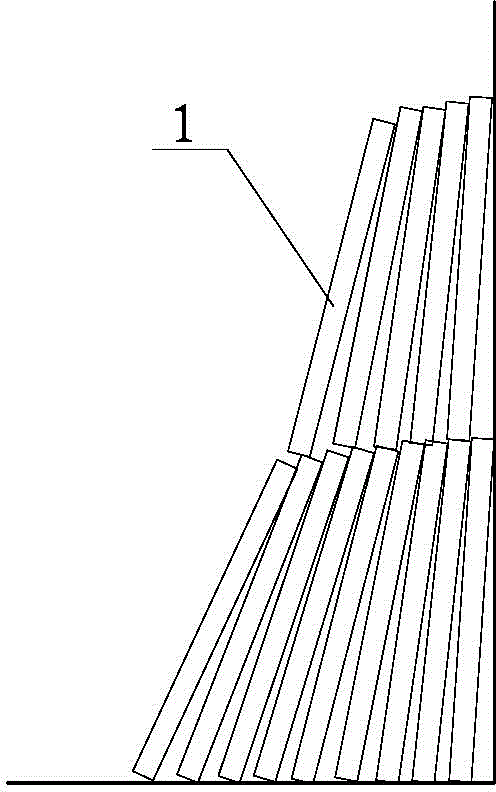

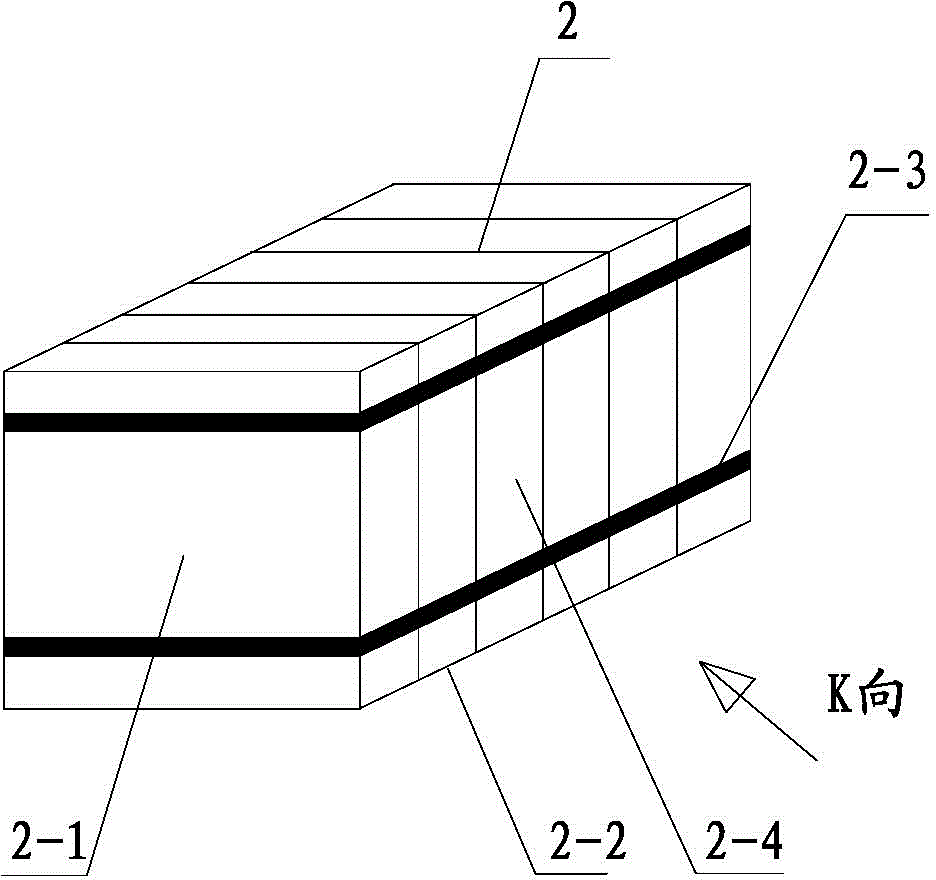

Ceramic tile stack, and stacking method

A ceramic tile and palletizing technology, applied in the field of ceramic tile storage, can solve the problems of low warehouse utilization, collapse of stacks, and increased expenses, and achieve the effect of increasing the number of palletizing layers, utilizing warehouse space, and reducing storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as Figure 10 , 11 As shown, the overall hoisting equipment is set above the warehouse, and the hoisting equipment mainly includes a longitudinal traveling device, a lateral traveling device, a rotating device, a vertical moving device, a lifting frame 6, and a plate 66. Longitudinal traveling device comprises longitudinal guide rail 42, mobile frame 5 and guide wheel 41; Lateral traveling device comprises transverse guide rail 4, guide wheel 43; Rotation device comprises toothed disc 51, external gear 53, toothed disc centering shaft 58; Vertical mobile device Including hoisting machine 52, wire rope 54;

[0060] Horizontal guide rail 4 is fixed on the wall of warehouse upper space, and the two ends of longitudinal guide rail 42 connect guide wheel 43, and guide wheel 43 is positioned at transverse guide rail 4 and can move left and right along transverse guide rail. Both sides of the mobile frame 5 are connected with guide wheels 41, and the guide wheels 41 are...

Embodiment 2

[0068] Such as Figure 12 As shown, the present embodiment is compared with the first embodiment. In the present embodiment, the vertical moving device includes a vertical guide rail 55, a climbing frame 56, and guide wheels 57; the rotating device includes a motor 59 and a rotating column 67. The vertical guide rail 55 links to each other with the mobile frame 5, and the climbing frame 56 connects the guide wheels 57; .

[0069] The working process of the present embodiment is set forth below:

[0070] The front, rear, left, and right position adjustments of the mobile frame 5 are the same as those in Embodiment 1, and will not be repeated here. After the mobile frame 5 adjusted the position, the motor drives the guide wheel 57 to rotate, and the climbing frame 56 climbs up and down along the vertical guide rail 55 and moves. For the process of hoisting the container package of tiles, refer to Embodiment 1, and details are not repeated here.

[0071] When the direction of r...

Embodiment 3

[0073] Such as Figure 13 Shown, when loading, the horizontal pulling device that control flashboard 66 can be extracted from the bottom of the tile container can adopt hydraulic cylinder 68. The hydraulic cylinder 68 is connected with the vertical plate 62 , and the hydraulic cylinder 68 is located in the lifting frame 6 . Hydraulic oil cylinder 68 works, promotes riser 62 and inserts plate 66 and extracts out from the bottom of ceramic tile assembly bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com