Movable type inclined jacking and bundling equipment, system and method

A mobile, top-supporting technology, applied in the direction of strapping materials, parts of strapping machinery, building materials packaging, etc., can solve problems such as difficulty in meeting the needs of flat laying, stacking and strapping, poor applicability, etc., to improve the efficiency of automatic conveying and operation. High, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

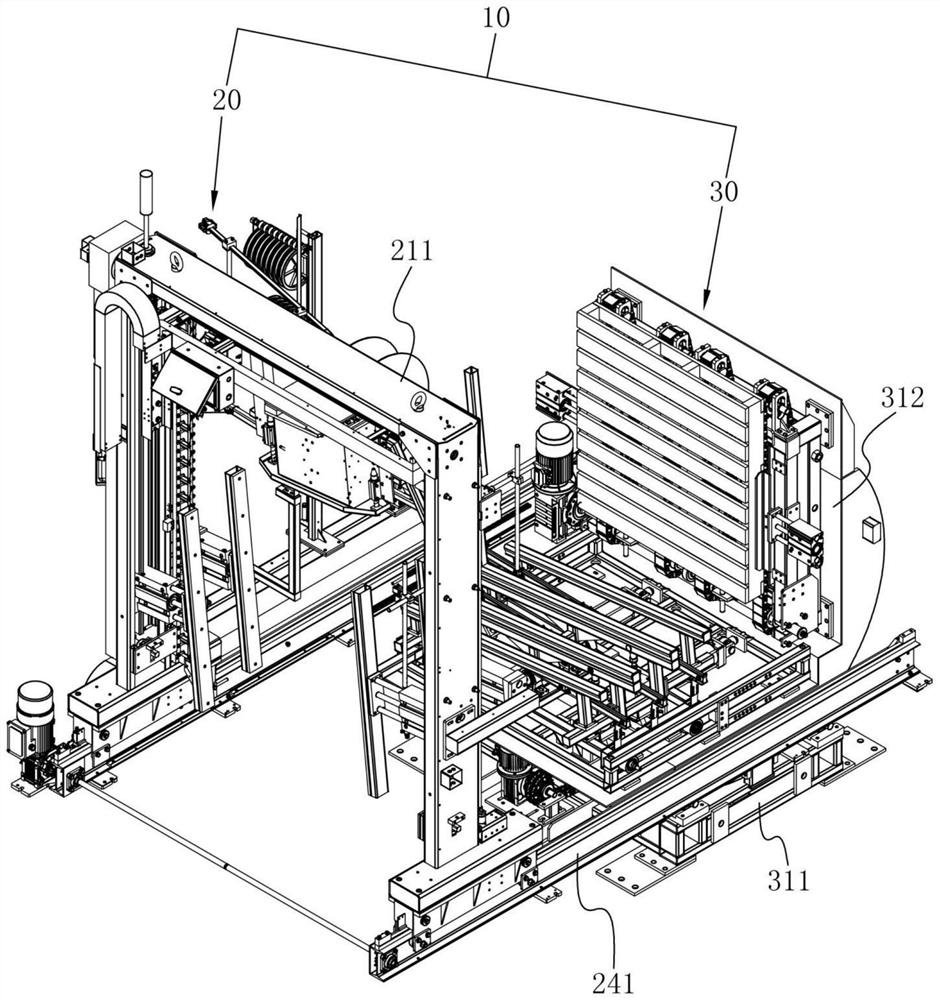

[0043] refer to figure 1 , a mobile inclined jacking strapping equipment 10, including a strapping device 20 and a turning device 30.

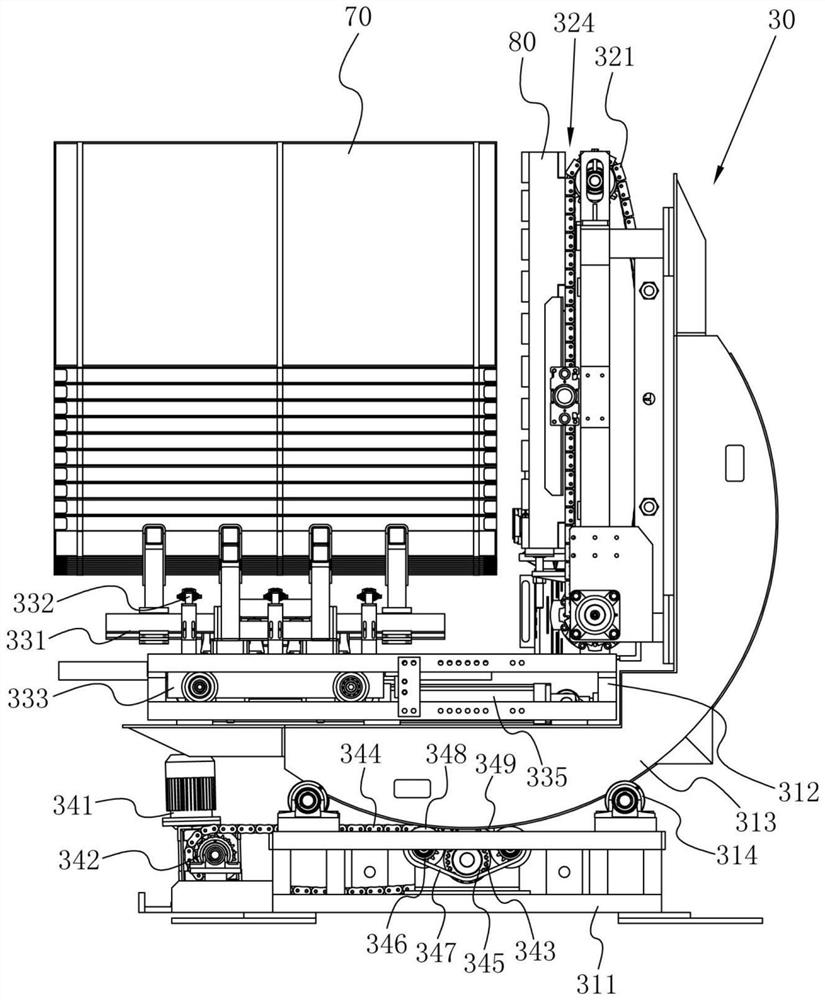

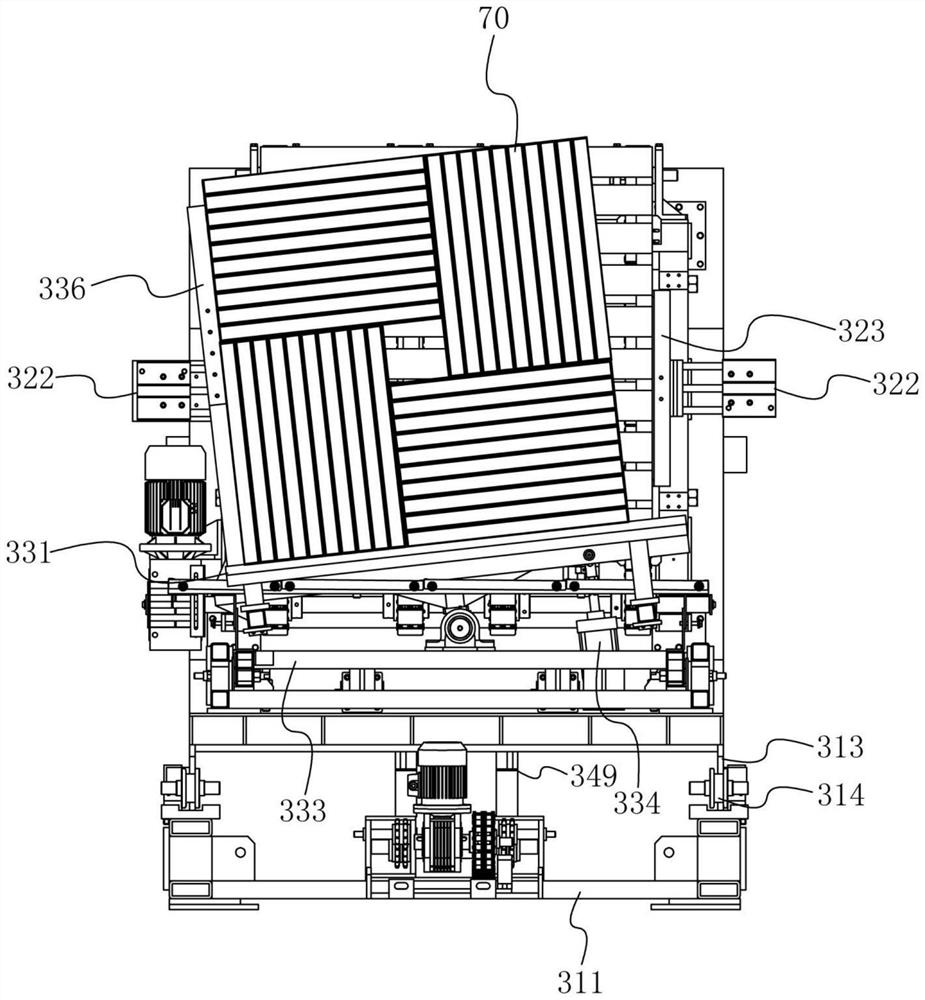

[0044] refer to figure 2 and image 3 , the turning device 30 includes a base 311 , a turning frame 312 , a tray conveying mechanism 321 , a binding belt path 332 and a tilting bracket 331 . The overturning frame 312 is rotatably installed on the base 311, the overturning frame 312 is fixedly connected with a support plate 313, the base 311 is rotatably connected with a support guide wheel 314 abutting against the support plate 313, and the overturning frame 312 supports the guide wheel during rotation. The wheels 314 can keep in contact with the supporting plate 313 , and provide supporting force for the supporting plate 313 and the overturning frame 312 , so that the overturning frame 312 can rotate on the base 311 . The base 311 is fixedly equipped with an overturning driver, and the overturning driver adopts an overturning reduction mo...

Embodiment 2

[0083] refer to Figure 6 , a mobile tilting jacking and bundling system, including an automatic pallet warehouse 40, a code packaging device 50, a logistics delivery device 60 and the mobile tilting jacking and bundling equipment 10 in Embodiment 1, the automatic pallet warehouse 40 is located on the pallet One side of the placement position 324 is used to place the pallet on the tray placement position, the code package device 50 is arranged on the other side of the tray placement position and is used to place the objects to be bundled on the inclined bracket, and the logistics conveying equipment 60 It is arranged on one side of the conveying direction of the pallet conveying mechanism 321 and is used for conveying bundled objects. The automatic pallet warehouse 40 includes a pallet warehouse 41 and a pallet robot 42 , pallets are preset in the pallet warehouse 41 , and the pallet robot 42 is used to transport the pallets in the pallet warehouse 41 to the pallet placement p...

Embodiment 3

[0087] refer to Figure 7, a mobile tilting jacking strapping system, the difference between it and Embodiment 2 is that the automatic pallet warehouse 40, the code package equipment 50 and the mobile tilting jacking strapping equipment 10 in Embodiment 1 are all provided with a plurality of , there is a one-to-one correspondence between a plurality of automatic pallet warehouses 40 , code package equipment 50 and mobile inclined jacking and strapping equipment 10 .

[0088] This embodiment has the following advantages:

[0089] Through a plurality of automatic pallet warehouses 40, packaging equipment 50 and mobile inclined jacking and binding equipment 10, the function of multi-line binding can be realized, and the production efficiency can be effectively improved, and the finished products can be bundled through one logistics conveying equipment 60 Carrying out transportation and improving the use efficiency of the logistics conveying equipment 60 has the advantage of bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com