Brick stacking device, method for controlling arrangement manner of stacked bricks and brick stacking machine

An arrangement method and stacking machine technology, which is applied in building material packaging, object stacking, transportation and packaging, etc., can solve problems such as high labor intensity, achieve the effect of reducing labor and improving stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

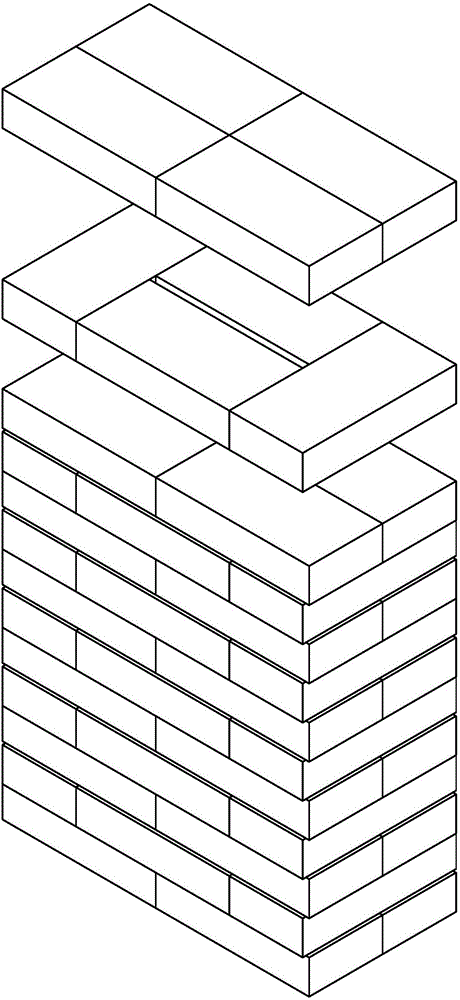

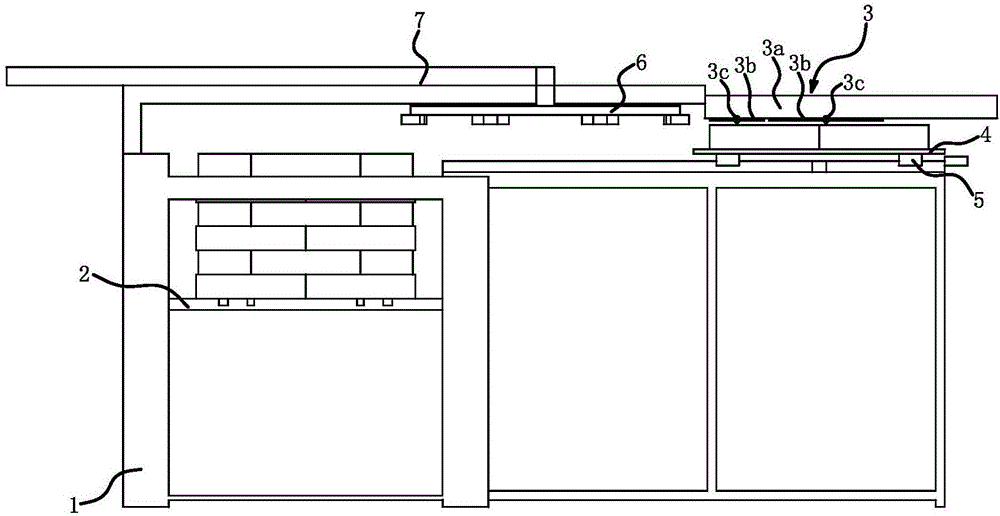

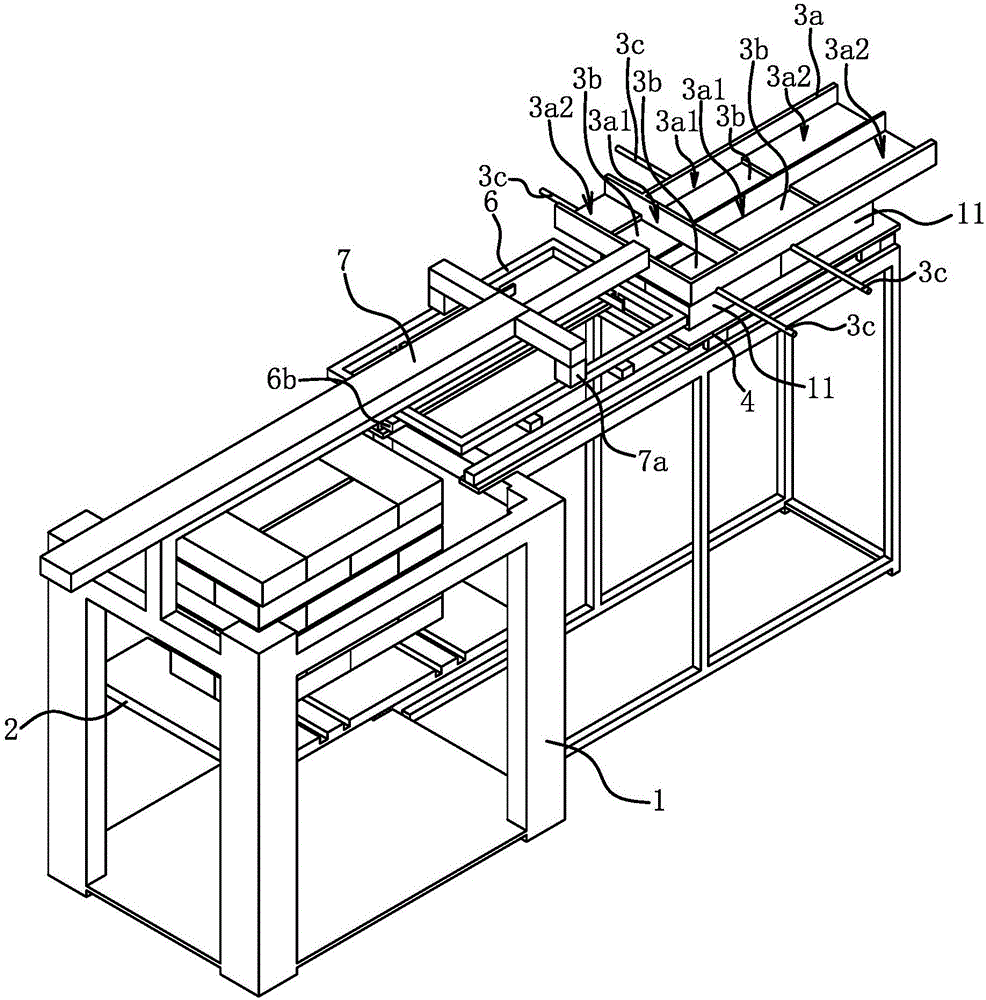

[0032] like figure 2 , image 3 and Figure 4 As shown, the brick stacking machine includes a frame 1, a stacking platform 2 and a brick stacking device 3.

[0033] The frame 1 is a frame mechanism, and the frame 1 is welded by metal pipes and metal plates.

[0034] The stacking platform 2 is connected to the frame 1 through a first guiding and driving mechanism capable of lifting and moving the stacking platform 2; specifically, the first guiding and driving mechanism includes a plurality of sets of vertically arranged first guide rail assemblies and a second A winch, the guide rail of the first guide rail assembly is fixedly connected to the frame 1, and the slider of the first guide rail assembly is fixedly connected to the stacking platform 2; the housing of the first winch is fixed on the frame 1, and the winch wheel of the first winch A lifting rope is connected, and the top of the frame 1 is rotatably connected with a guide wheel, and the lifting rope walks around t...

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described. The difference is that the brick sorting and clamping mechanism 6 includes a rectangular outer frame 6a And be positioned at outer frame 6a inside two finishing clamping rods, two finishing clamping rods are vertically arranged and two finishing clamping rods and two inner sides of outer frame 6a are arranged in parallel, arrange between clamping rods and outer frame 6a The room is connected by the third cylinder and the guide rod. By controlling the piston rod of the third cylinder to stretch out, the clamping rod pushes the bricks 11 and cooperates with the outer frame 6a to realize orderly arrangement of the four bricks 11 and clamping of the four bricks 11; by controlling the third The piston rod retraction of cylinder realizes releasing brick 11.

Embodiment 3

[0050] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the differences lie in:

[0051] like Figure 10 As shown, the brick stacking machine includes a frame 1, a stacking trolley 8 and a brick stacking device 3.

[0052] The frame 1 is fixed on the ground, the frame 1 is flat, the top of the frame 1 has a slide rail 1a, the wheels of the stacking trolley 8 are arranged on the slide rail 1a, and the frame 1 is provided with a second winch and a reversing wheel , the winch of the second winch is connected with a traction rope, and the traction rope is connected with the stacking trolley 8 through the reversing wheel, and then the stacking trolley 8 moves horizontally along the slide rail 1a by manipulating the second winch.

[0053] The brick stacking device 3 includes a brick temporary storage platform 3 a and a brick carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com