Pallet-free building block stacking and packaging assembly line

A pallet-less, assembly-line technology, applied in the field of assembly lines, can solve the problems of manufacturers increasing costs and wasting pallets, etc., and achieve the effect of saving expenses and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

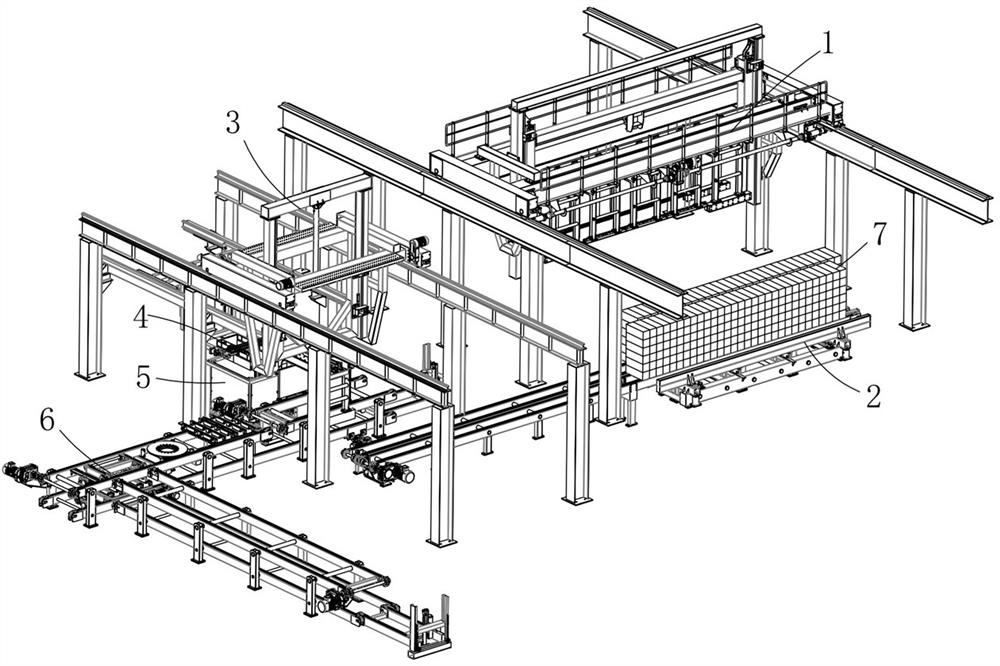

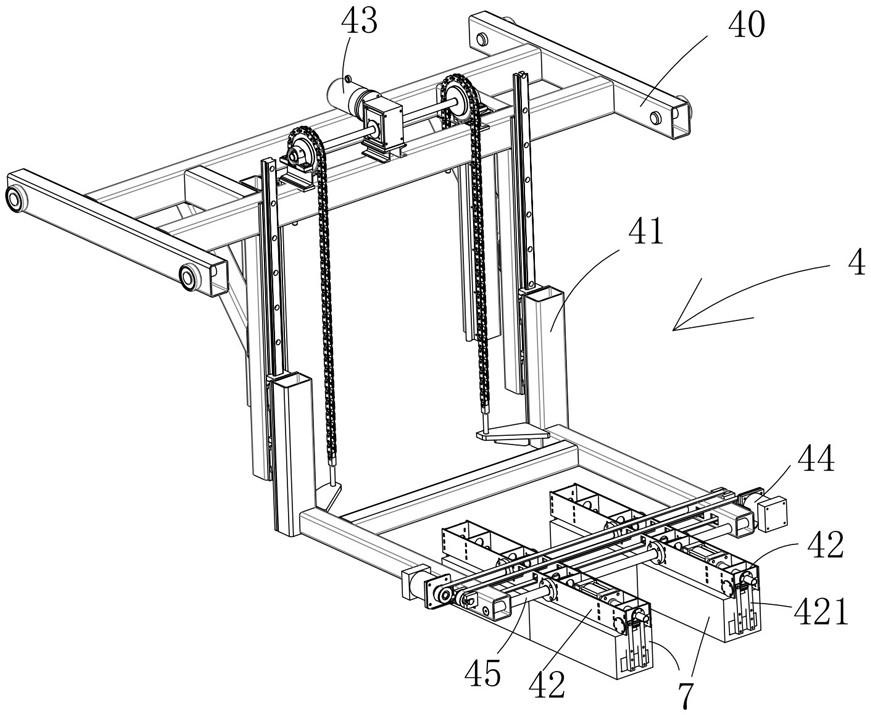

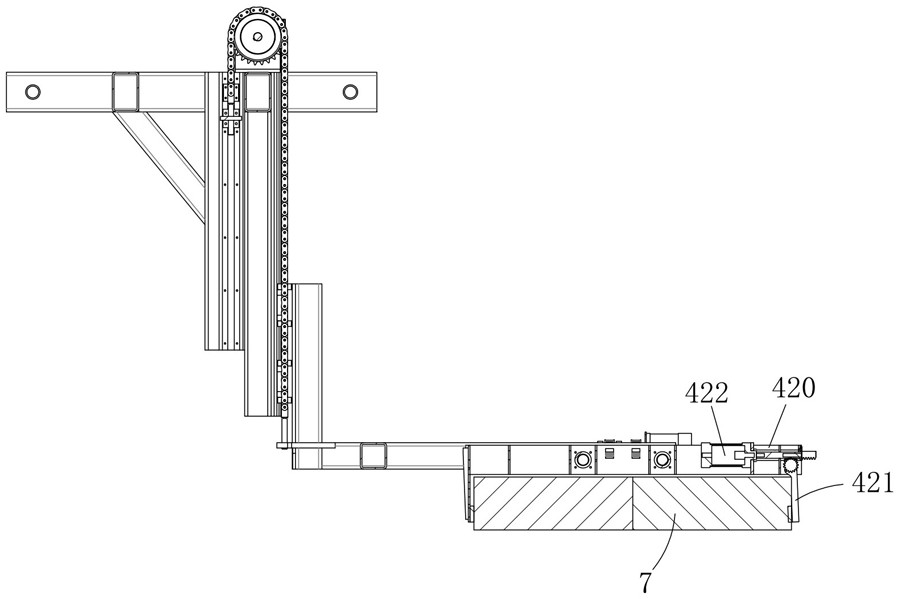

[0033] Such as figure 1 As shown, this pallet-less block stacking and packaging line includes a block transfer spreader 1 , a double-mode conveying device 2 , a block rotating spreader 3 and a pallet circulation conveying device 6 . The block transfer spreader 1 is used to transfer a row of blocks 7 to the dual-mode conveying device 2, and the dual-mode conveying device 2 merges the two rows of blocks together and transports them to the front; the block rotating spreader 3 is used to transfer The double-row blocks on the dual-mode conveying device 2 are partially transferred to the pallet 8 of the pallet circulating conveying device 6, and the pallet circulating conveying device 6 transports the blocks into the binding station.

[0034] In order to solve the problems existing in the prior art, the present invention proposes a brand-new bundling scheme: use the block rotating hanger 3 to stack the blocks 7 into such Figure 8 A pile of blocks shown (blocks of the layer with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com