Production line capable of separating building blocks and supporting plates and stacking building blocks

A production line and block technology, which is applied in the field of block making, can solve the problems of easy loosening of brick stacks, low production efficiency, and excessive size, and achieve the effects of simple process, small clamping force, and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

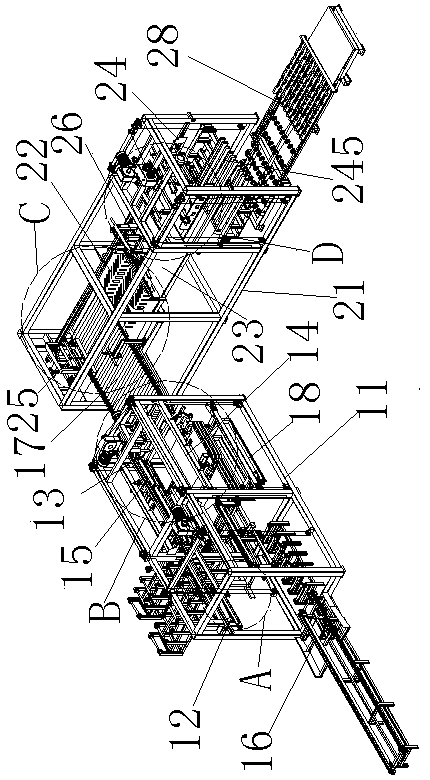

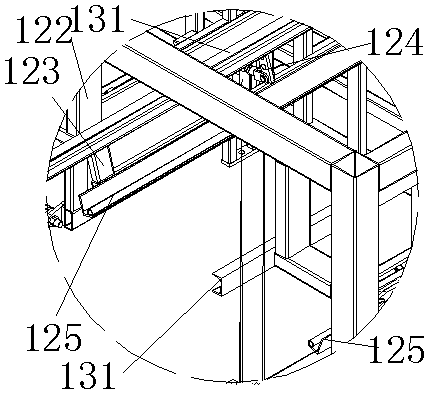

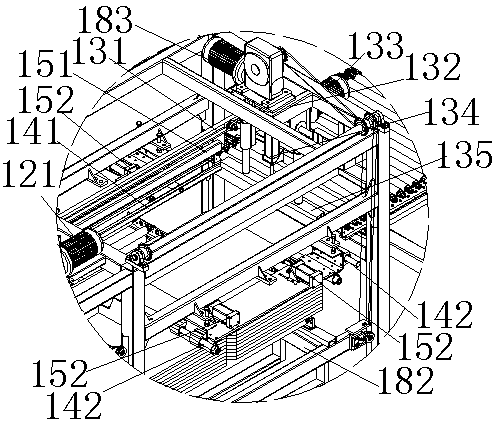

[0032] Example 1. Such as Figure 1-35 As shown, a production line capable of separating blocks from pallets and stacking blocks includes a block pallet separation system, a block stacking system, and a control device. The block pallet separation system includes a block pallet separation system frame 11, a liftable grab board mechanism 12 installed on the block pallet separation system frame 11, a third liftable push device 13 that can move forward and backward, Movable supporting plate mechanism 14, shaping mechanism 15, plate pile conveying device 16, building block conveying roller group 17, block board conveying device 18. The controls are not shown in the drawing.

[0033] The plate stack conveying device 16 is located on the ground at the front end of the frame and a part is inserted into the bottom end of the front end of the frame 11 of the block pallet separation system. top. The pallet grabbing mechanism 12 is installed above the insertion part of the pallet conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com