Ceramic tile redundant binding method and binding machine

A ceramic tile and strapping machine technology, which is applied in the field of ceramic tile packaging technology, and the field of automatic strapping of ceramic tiles, can solve the problems of inability to achieve continuous work, low production efficiency, frequent shutdowns, etc., and achieve high-efficiency packaging operations and work efficiency High, solve the effect of high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

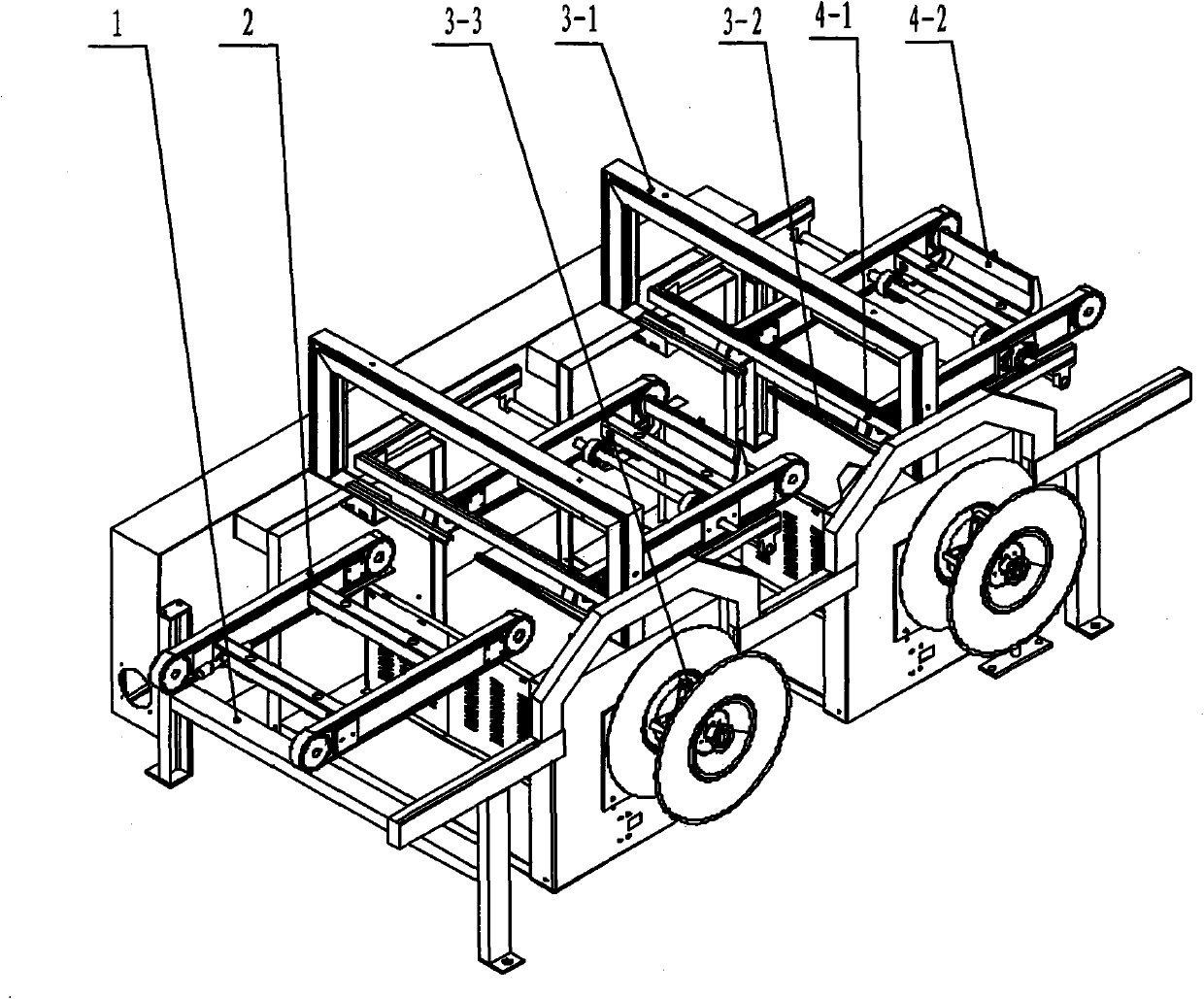

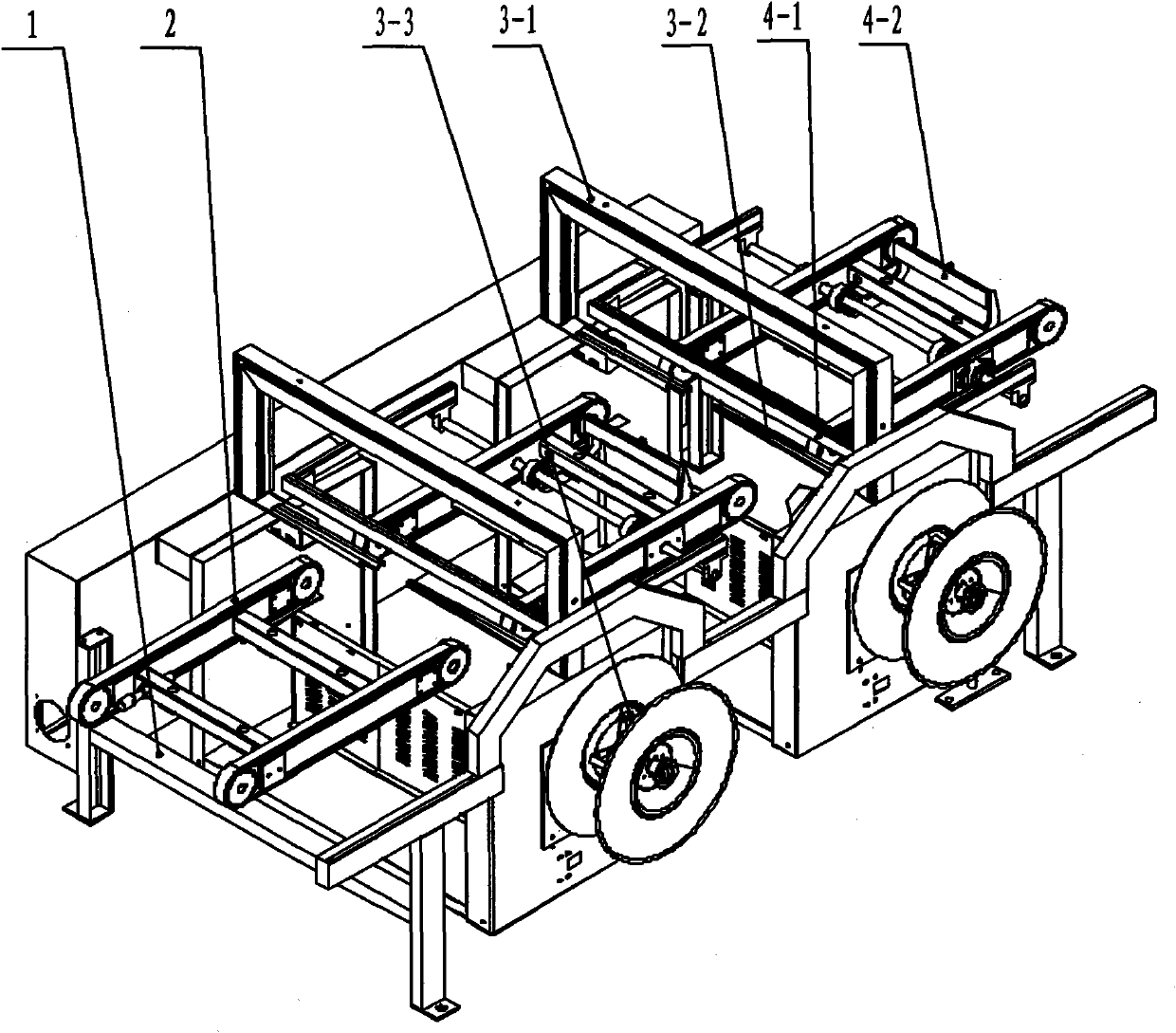

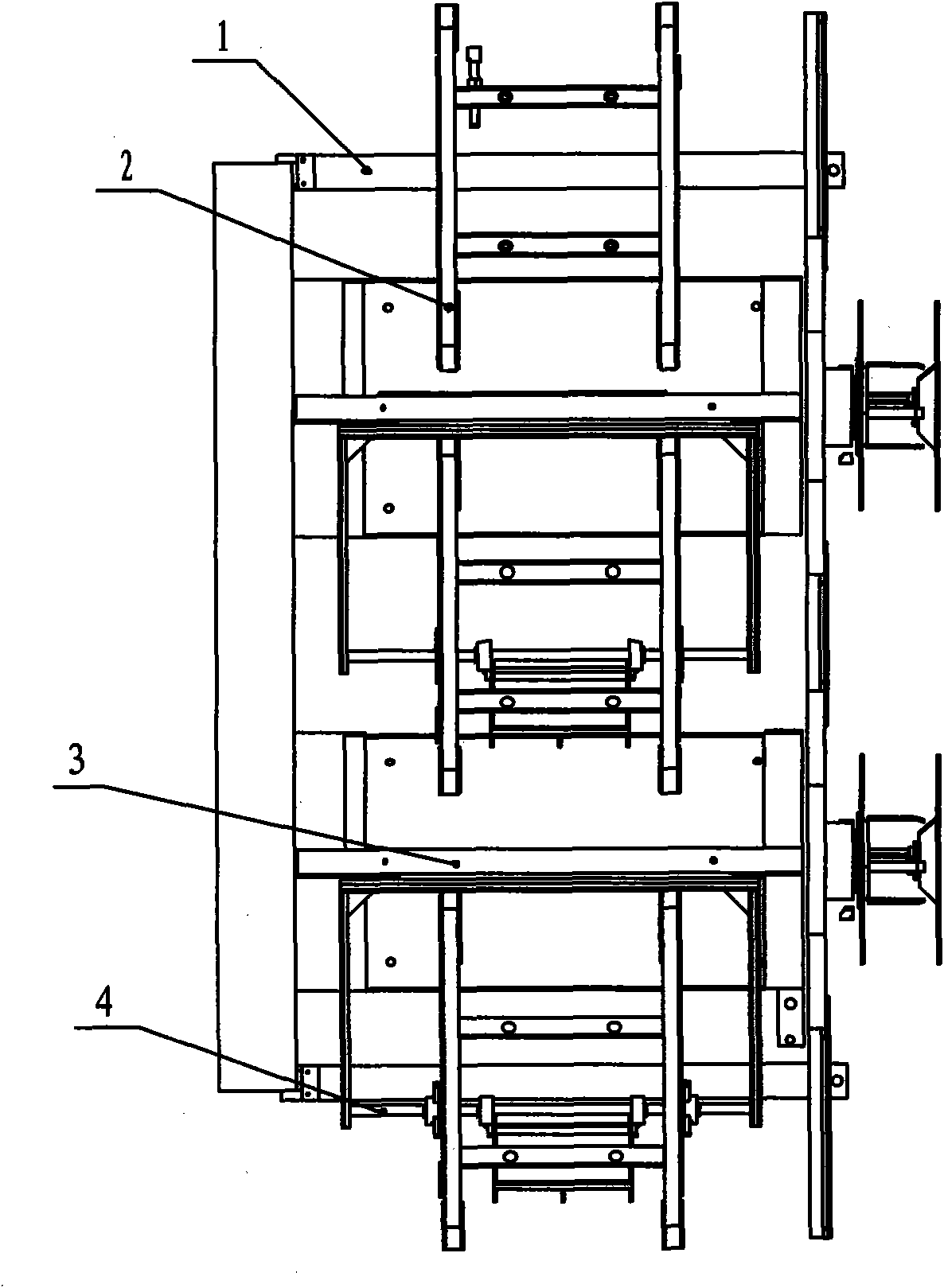

[0015] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, this embodiment comprises frame 1 and the feeding device 2 that is arranged on it, strapping device 3, positioning block brick device 4 and electric control system, it is characterized in that strapping device 3 comprises two or more annular Frame 3-1, movement 3-2 and tape roll 3-3; The positioning block device corresponding to the binding device includes a front block mechanism 4-1 (for positioning when the first band is played) and a rear block mechanism 4-2 (for positioning when playing the 2nd tape).

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the annular frame 3-1 is a rectangular frame arranged in parallel, and there is a belt path inside it so that the packaging tape can be wound on the surface of the brick bag; other composition and connection methods It is the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one is that two or more cores 3-2 are arranged in the same direction, and the core includes a main motor, a worm reducer, and controls each executive member (upper slide plate) , T-shaped slide block, top knife, etc.) cam mechanism, tape feeding mechanism, tape receiving mechanism, tensioning mechanism, bonding mechanism, etc. of coordinated work;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com