Automatic brick packaging system and packaging method thereof

A brick and automatic technology, which is applied in the field of brick palletizing and packaging, can solve the problems of low production efficiency, large floor space, easy to scatter bricks, etc., and achieve the effects of improving production efficiency, flexible and compact layout, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

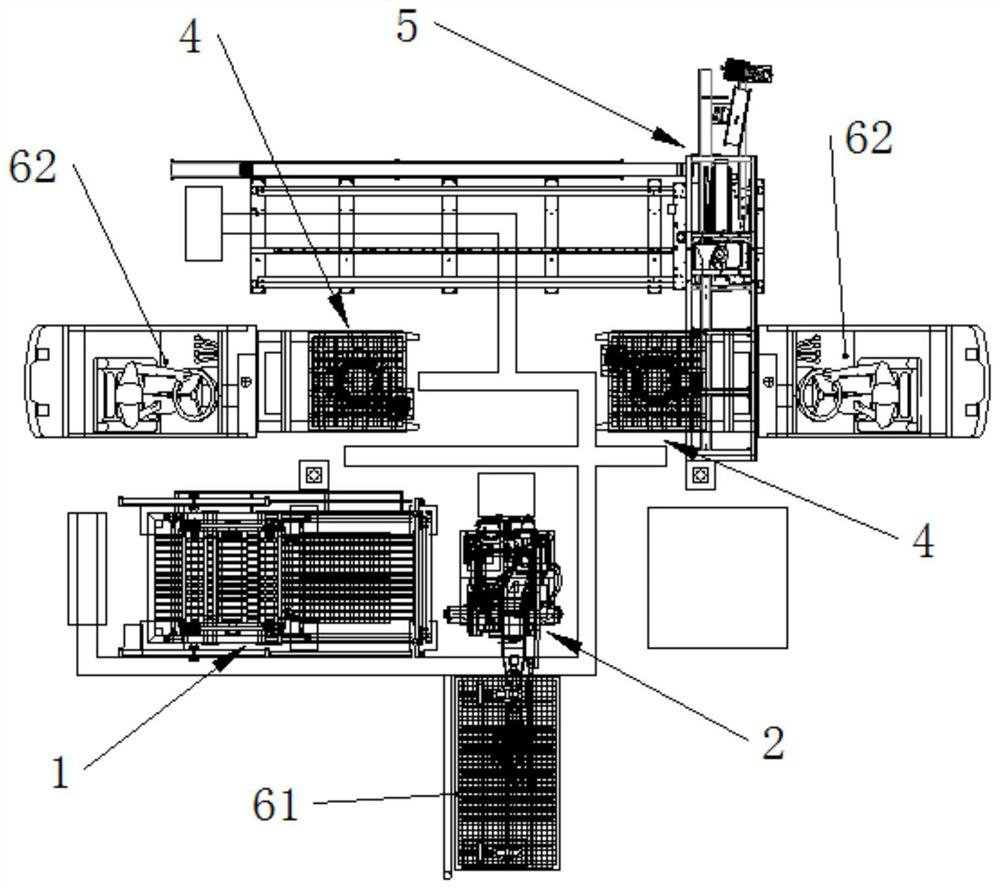

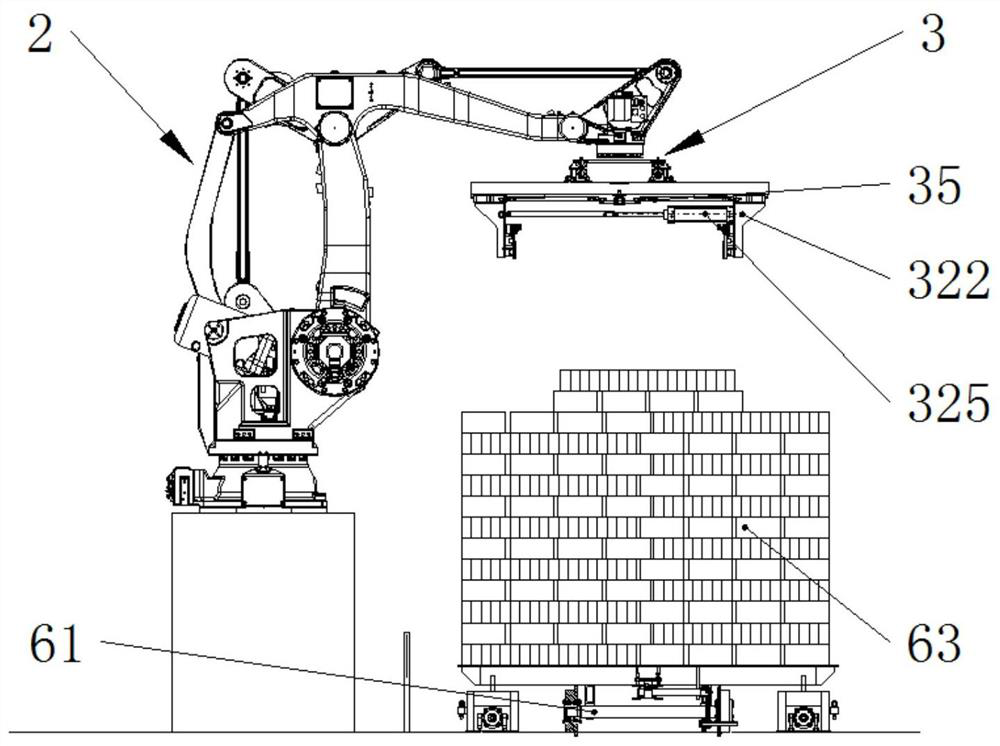

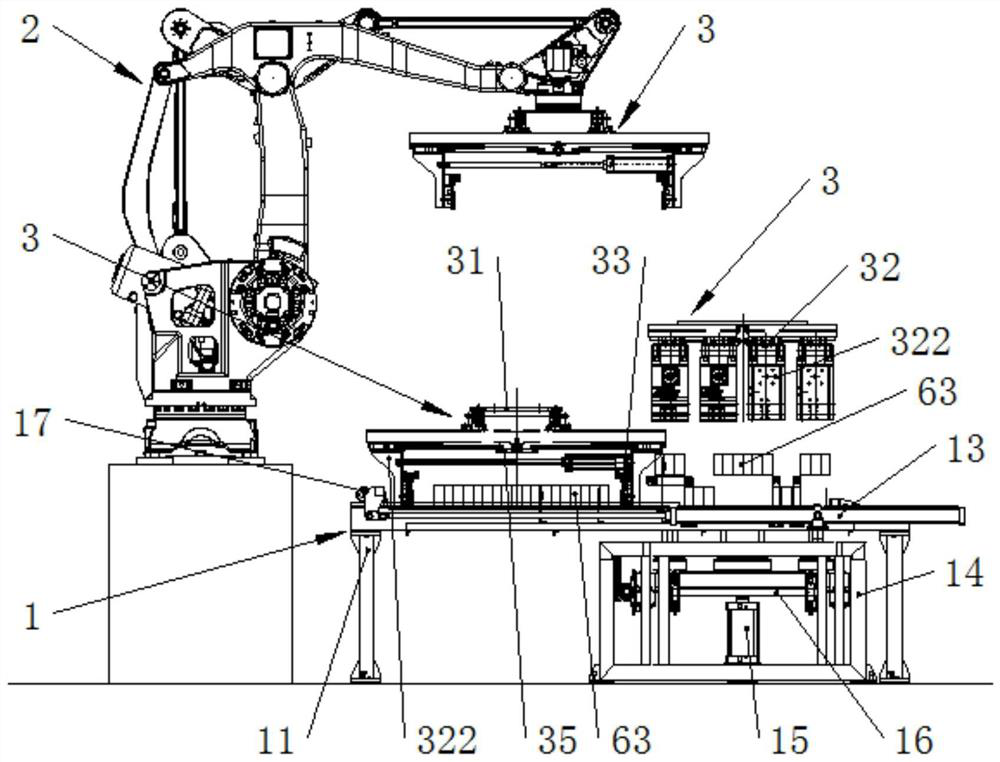

[0049] see Figure 1-13 , an automatic packing system for bricks, comprising a brick splitter 1, an industrial robot 2, a stacking manipulator 3 fixed to the mechanical arm of the industrial robot 2, a turntable device 4, an automatic packing machine 5, a blank car 61 and Forklift 62; bricks 63 are placed on the blank car 61; the brick splitter 1 is used to split the bricks 63 and reserve holes for forklifts; the stacking manipulator 3 can clamp the bricks 63 And close up the gap between the bricks 63; the stacking manipulator 3 can move the bricks 63 on the blank car 61 to the brick splitter 1 or the turntable device 4, or move the bricks 63 on the blank car 61 The bricks 63 that have been reserved for forklift holes on the brick splitter 1 are moved to the turntable device 4; the turntable device 4 can be rotated by 90°, which is convenient for double-sided stacking of the brick stack 64 formed after the bricks 63 are stacked. Packing; the automatic packing machine 5 is use...

Embodiment 2

[0094] see Figure 14-16 The difference between this embodiment and Embodiment 1 is that the horizontal conveying assembly 13 is a conveying mechanism 12 and a power mechanism for driving the conveying mechanism 12 to rotate.

[0095] An automatic packaging system for bricks, comprising a brick dividing machine 1, an industrial robot 2, a stacking manipulator 3 fixed to the mechanical arm of the industrial robot 2, a turntable device 4, an automatic packing machine 5, a blank car 61 and a forklift 62; bricks 63 are placed on the blank car 61; the brick splitter 1 is used to split the bricks 63 and reserve holes for forklifts; the stacking manipulator 3 can clamp the bricks 63 and Close the gap between the bricks 63; the stacking manipulator 3 can move the bricks 63 on the blank car 61 to the brick splitter 1 or the turntable device 4, or move the splitter 63 The bricks 63 that have been reserved for forklift holes on the brick machine 1 are moved to the turntable device 4; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com