L-shaped distribution structure of valve hall converter transformer of extra-high-voltage direct-current converter station

A converter transformer and UHV DC technology, applied in the field of electric power buildings, can solve the problems of large occupation area, long time, and difficult steering of the converter station, reduce the initial investment cost, small footprint, and simplify the square. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

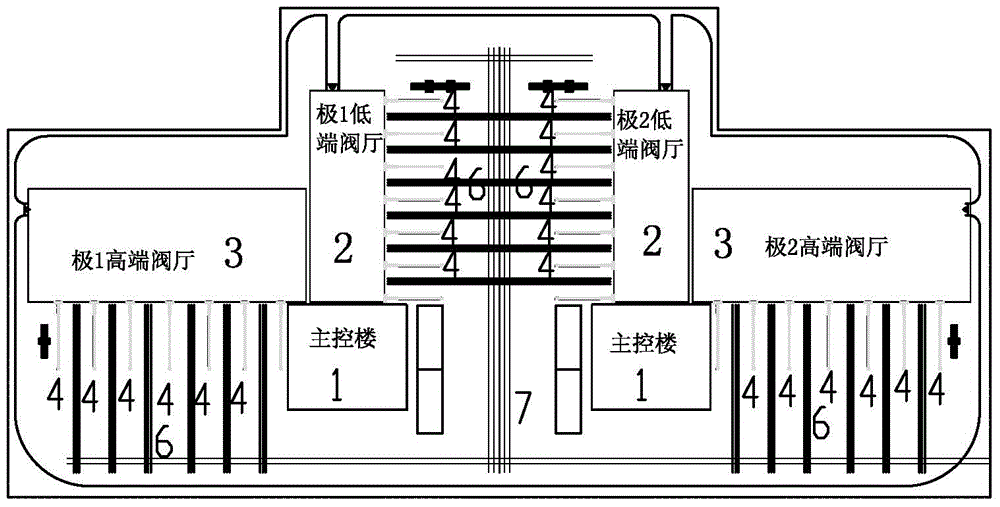

[0024] refer to figure 1 , this embodiment includes two main control buildings 1, two low-end valve halls 2, two high-end valve halls 3 and several converter transformers 4, the main control building 1, low-end valve halls 2, high-end The valve hall 3 and the converter transformer 4 are distributed in left and right mirror images, among which, the low-end valve hall 2 and the high-end valve hall 3 are arranged behind the main control building 1 in an L-shaped distribution, and the bottom-end valve hall 2 is longitudinally distributed in the main control building 1. On the back side of the control building 1, the high-end valve hall 3 is laterally distributed on the outside of the low-end valve hall 3; a part of the converter transformer 4 is distributed on the inner side of the low-voltage valve hall 2 in a horizontal "one" arrangement, and the converter The other part of the converter transformer 4 is distributed on the front side of the high-voltage valve hall 3 in a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com