Brick stacker system

A brick stacker and palletizer technology, which is applied in the stacking, loading/unloading, building materials packaging and other directions of objects, can solve the problems of easy collapse, damage to small bricks, and potential safety hazards, and achieves stable bricks and structures. Simple, labor-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

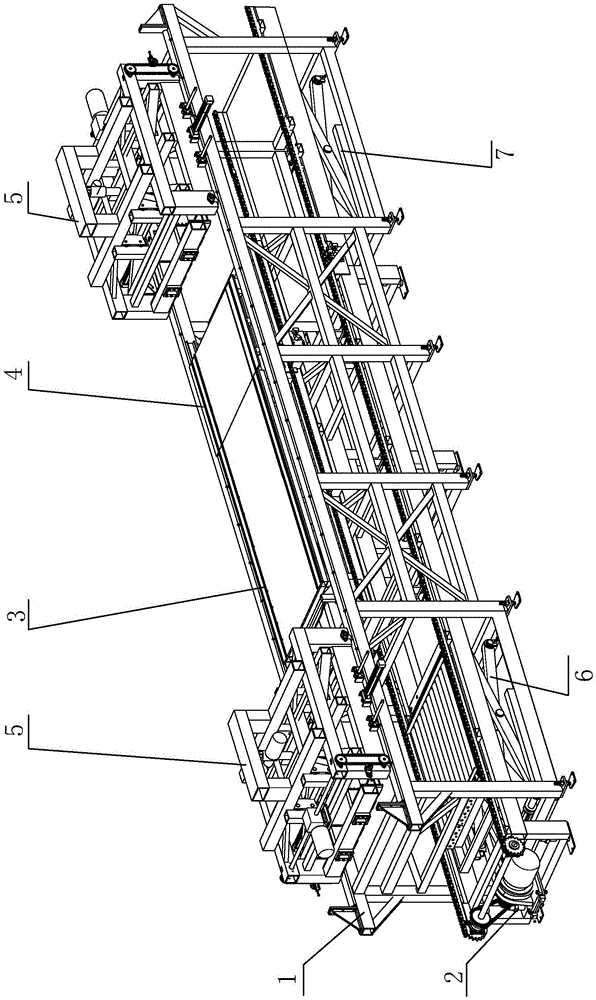

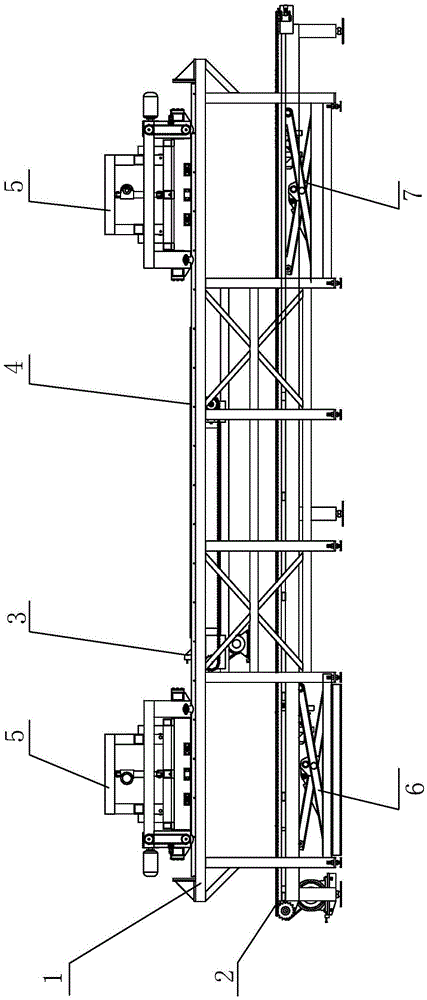

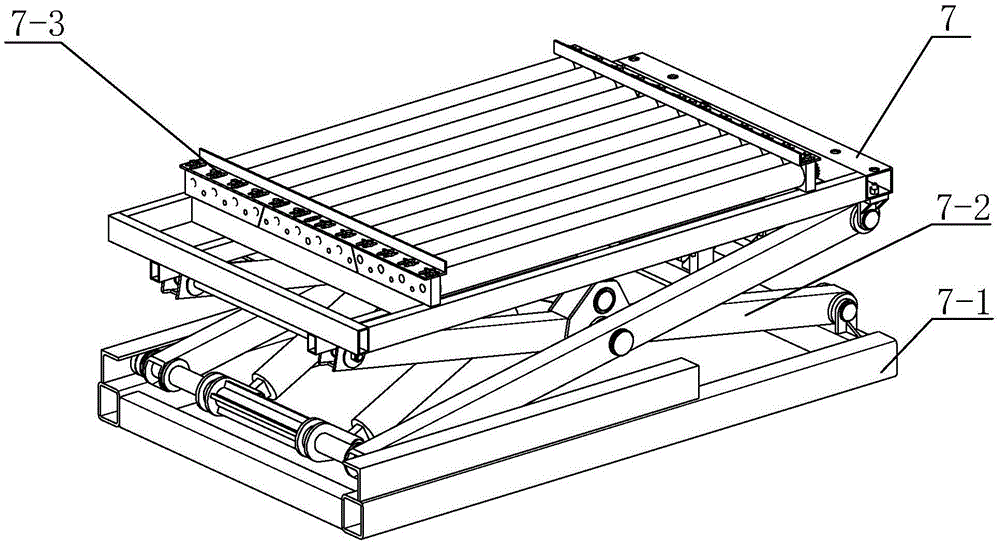

[0030] The present invention is a brick stacker system, such as figure 1 , 2 As shown, it includes a frame 1, a conveyor 2, a brick pushing mechanism 3, a brick counting mechanism 4, 2 fixture trolleys 5, a lifting roller machine 6, and a lifting rotary platform 7. The conveyor 2 is arranged on the bottom of the frame 1, the lift roller machine 6 is arranged directly below the conveyor 2, and the first clamp trolley is arranged on the top of the frame 1, and is positioned at the bottom of the lift roller machine 6. Above, the brick pushing mechanism 3, the brick counting mechanism 4, and the second clamping trolley are all arranged on the upper part of the frame 1, and are sequentially located in front of the conveying of the first clamping trolley, and a lifting rotary platform 7 is set below the second clamping trolley . The conveyor 2 is used to transport the pallet bricks to the lifting roller machine 6, and the lifting roller machine 6 is used to lift the pallet bricks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com