Brick stacking and packaging system and brick row placing and conveying method

A packaging system and brick row technology, applied in the field of balers, can solve the problems of difficult forklift insertion, complex structure of manipulator, poor reliability, etc., and achieve the effect of improving the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the present invention provides a brick row placing and conveying method, wherein, such as Figure 17 As shown, the bricks formed by stacking include a layer of bricks, each layer of bricks includes b rows of bricks, and each row of bricks includes m or n bricks, where m>n;

[0032] The method for placing and transporting brick rows includes: for the brick rows transported by the conveyor line, in the b row of brick rows in a layer of bricks used to form forklift holes, place n bricks in each row; and in the remaining layers of brick layers In the b row of bricks, m bricks are placed in each row; after the brick layer of a layer is stacked to form a brick stack, a forklift hole is formed in the corresponding brick layer where n bricks are placed in each row.

[0033] Specifically, during the brick stacking process, the forklift hole A is formed in a specific layer of bricks as required. For this reason, in the conveying process of the brick row, a relative...

Embodiment 2

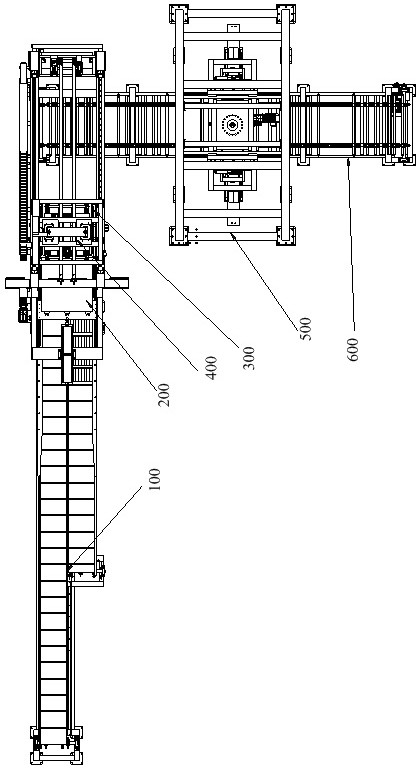

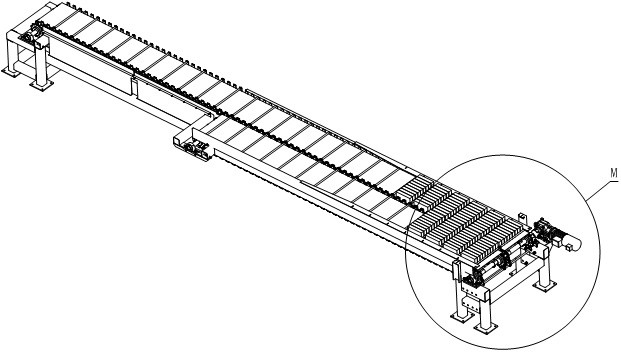

[0040] Embodiment two, such as Figure 1-Figure 7 As shown, the present invention provides a kind of code brick packing system, comprises:

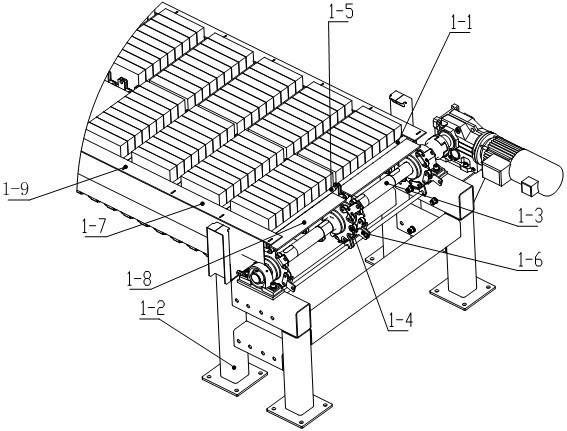

[0041] The first conveying line 100, the first conveying line 100 is equipped with a plurality of pushing parts 1-1 that can move cyclically, and a pushing space for pushing brick rows is formed between two adjacent pushing parts 1-1, and the pushing parts 1 -1 is also used for continuing to push the brick row for a set distance after the brick row leaves the tail end of the first conveying line 100;

[0042] The loading platform 300, the loading platform 300 is arranged at the tail end of the first conveying line 100 and is used to receive the brick rows output by the first conveying line 100 in sequence and form a brick layer;

[0043] The grabbing and palletizing mechanism 400 is used to grab the bricks on the loading platform 300 and stack them to form bricks;

[0044] The second conveying line 600, the second conveying line 600 is ...

Embodiment 3

[0072] Embodiment three, for packing equipment 500, it can adopt conventional packing equipment 500, and in order to realize cross-packing, then can be configured with two packing equipment 500, wherein one packing equipment 500 can pack bricks back and forth, and the other A packaging device 500 realizes packaging in the left and right directions, for details, please refer to the configuration method of a conventional packaging device 500 .

[0073] In order to effectively reduce the space occupied, the packing device 500 can adopt the method of rotation and translation packing, so that a single packing device 500 can complete the packing process in the cross direction, and the specific structure will be described in conjunction with the drawings.

[0074] Such as Figure 8-Figure 15 As shown, the packaging equipment 500 includes: a support frame 1 , a rotating module 2 and a translation packaging module 3 . The rotation module 2 includes a rotation guide 21, a rotation fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com