Fully-automatic gluing equipment suitable for various parts

A fully automatic, parts-based technology, applied in coatings, devices for coating liquid on the surface, etc., to achieve high production efficiency, good versatility, and uniform glue coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

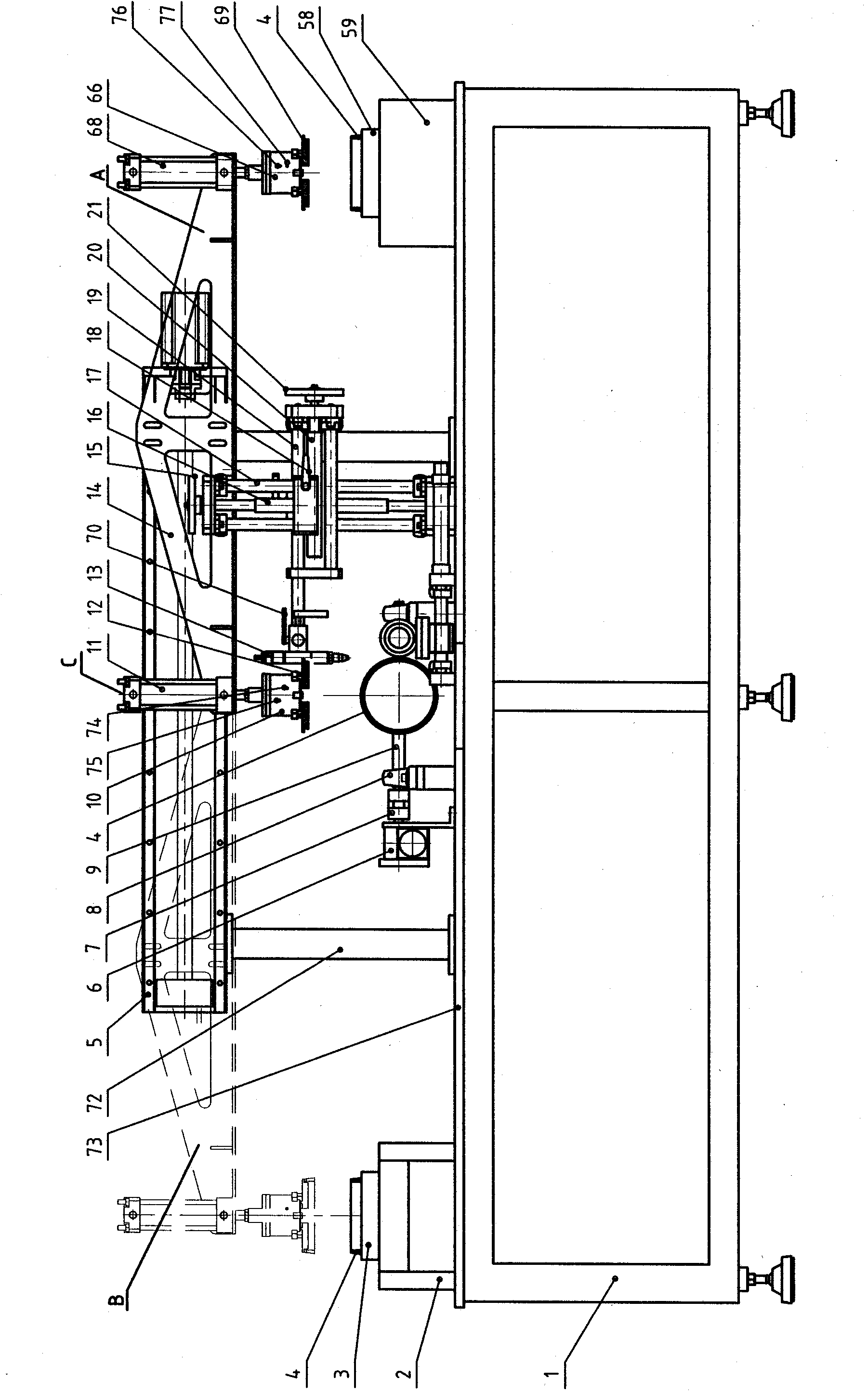

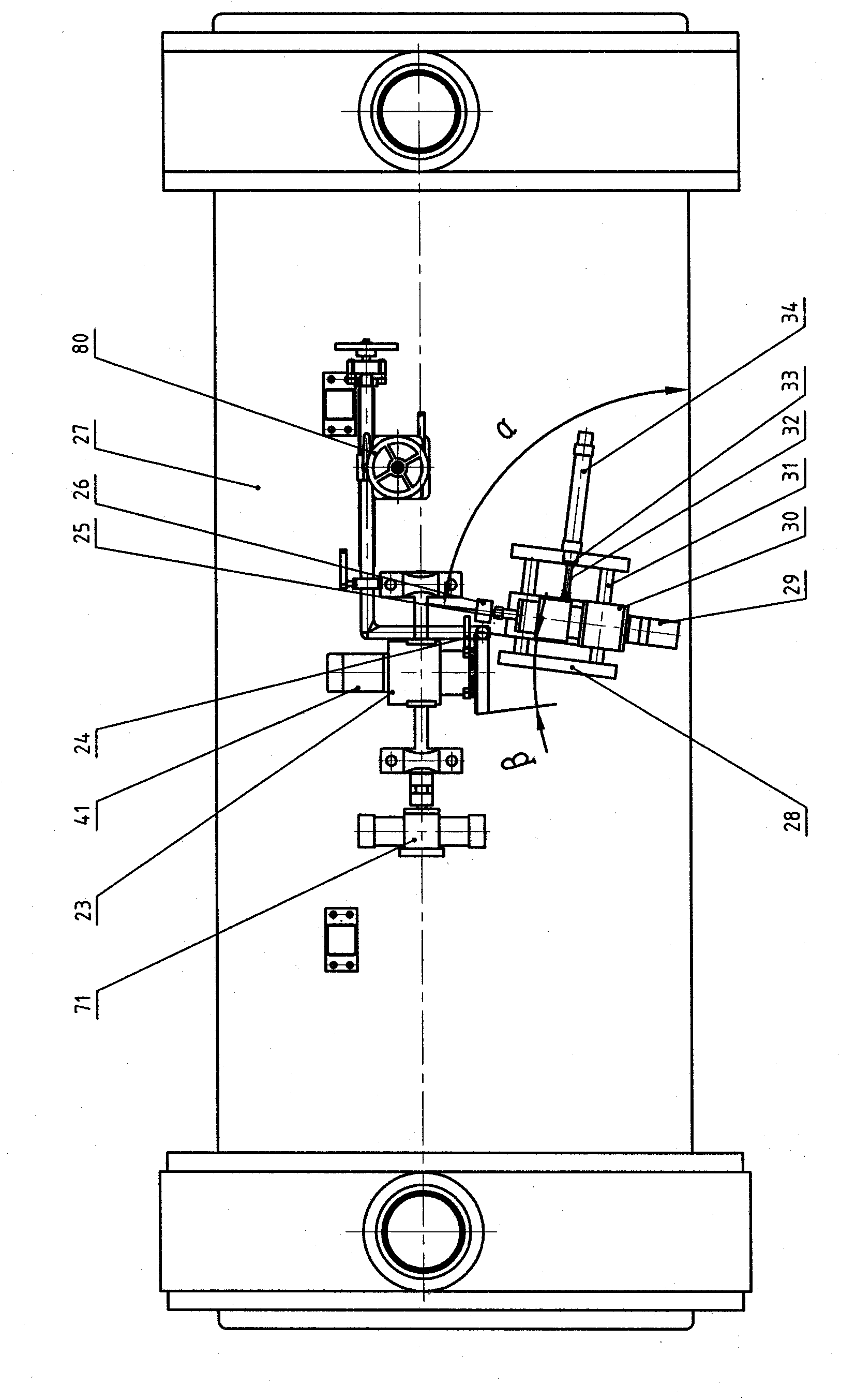

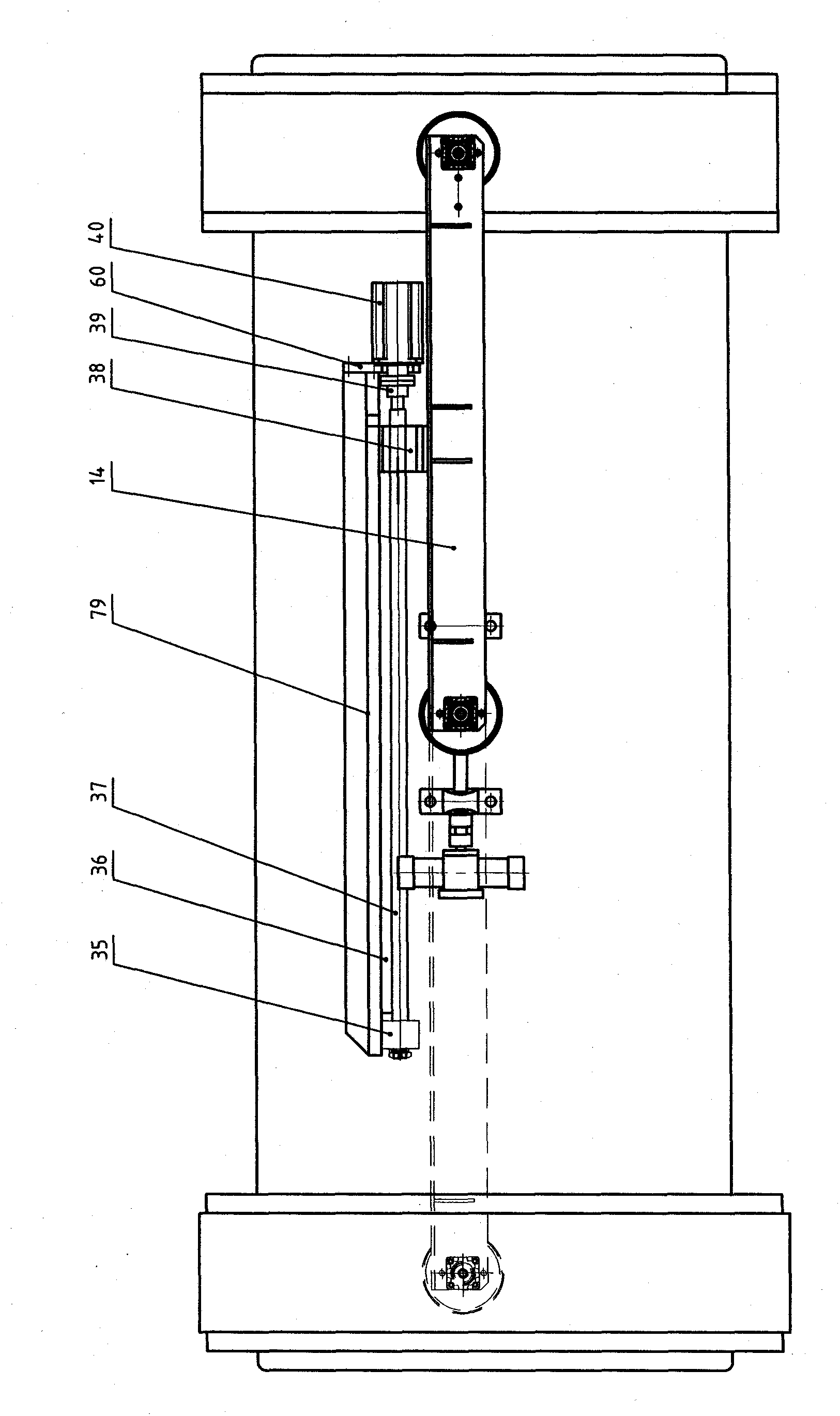

[0014] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 8 As shown, the fully automatic gluing equipment suitable for various parts described in this embodiment includes a feeding table 59, a transfer table 2, a parts lateral transfer device 5, a tensioning chuck A10, a tensioning chuck C10, a rotating The chuck device 23, the swing device, the rubber head adjusting device, the rubber scraping device, etc. are fixedly connected on the frame to form an integral body, the loading positioning mold 58 is fixed on the loading table panel 73, and the parts 4 are placed on the loading table manually. On the positioning mold 58, the function is to accurately position the parts 4, which is convenient for accurate and automatic handling of the parts 4. The conveyor belt 3 that can rotate continuously is installed on the conveyor table 2. Every time the parts are glued, it is a beat, and each time a beat is used, the chuck is te...

specific Embodiment approach 2

[0024] Specific implementation mode two: as Figure 6As shown, in this embodiment, the front view of the situation in which the feeding table 58 and the cylinder B68 are removed, the swing device 71, the rotating chuck device 23, the rubber head adjustment device 80, the rubber head adjustment device, and the rubber coating device 28 is exactly the same as the specific embodiment one, except that the loading workbench 58 and the cylinder B68 etc. are removed, the frame 1, the workbench panel 73, the parts transverse transfer device 5, and the mobile frame 14 are shortened, and the working position becomes C , B two, its principle of action is basically the same as the specific embodiment one. The conveying table 2, parts transverse conveying device 5, tensioning chuck A10, tensioning chuck C10, rotating chuck device 23, swinging device 71, rubber head adjusting device 80, rubber coating device 28, etc. described in this embodiment It is fixed and integrated on the frame, and ...

specific Embodiment approach 3

[0025] Specific implementation mode three: as figure 1 , Figure 6 As shown, in this embodiment, the conveyor belt 3 is stopped or removed, and the other action principles are basically the same as those in Embodiment 1 and Embodiment 2. It is just that after the parts transverse conveying device 5 transports the parts 4 from the C position to the B position, it is released onto the conveyor belt 3, and the parts 4 are manually removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com