Full-automatic clamping hoop used for seabed jacket repairing

A jacket, fully automatic technology, applied in the direction of pipe supports, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of not realizing fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

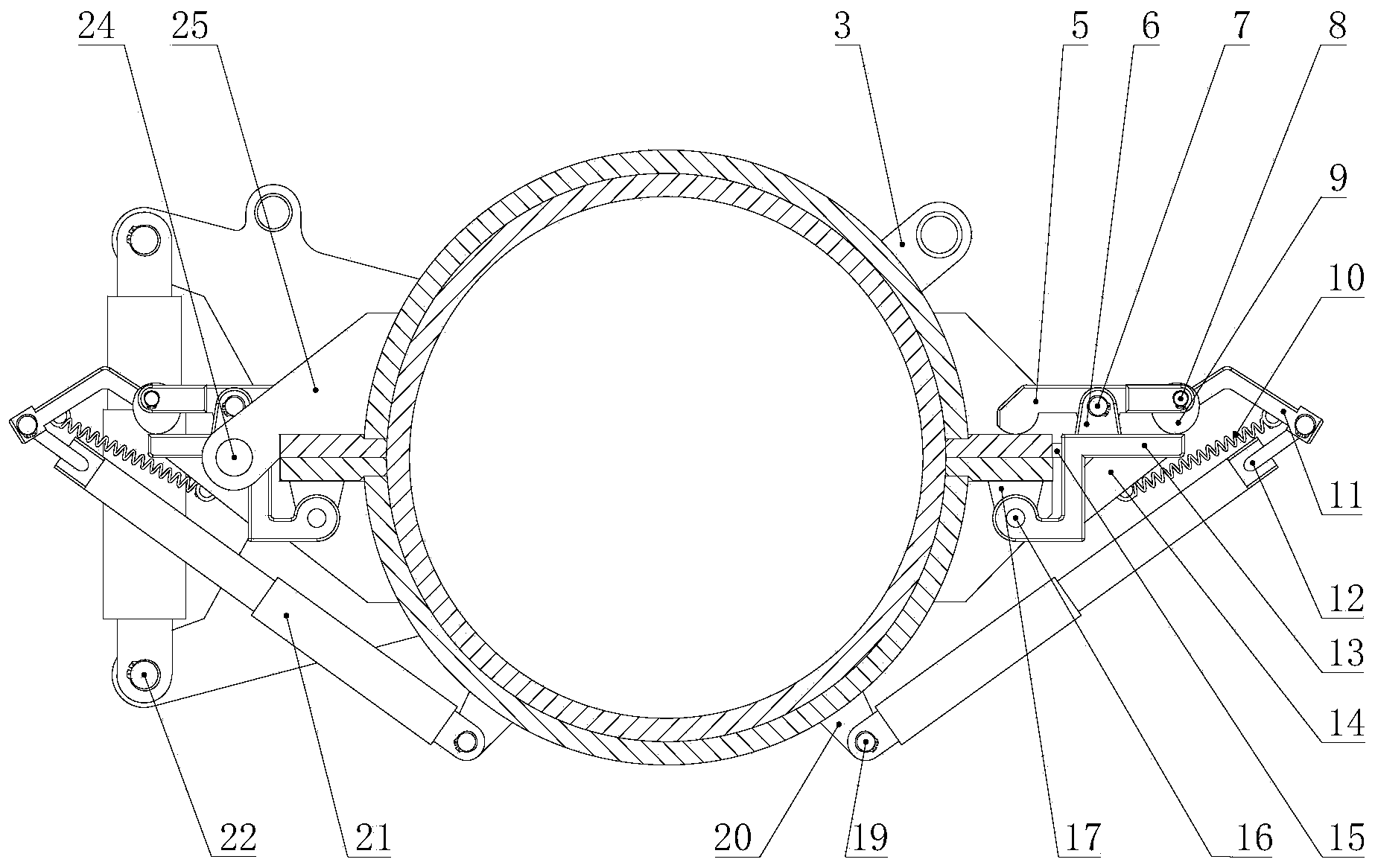

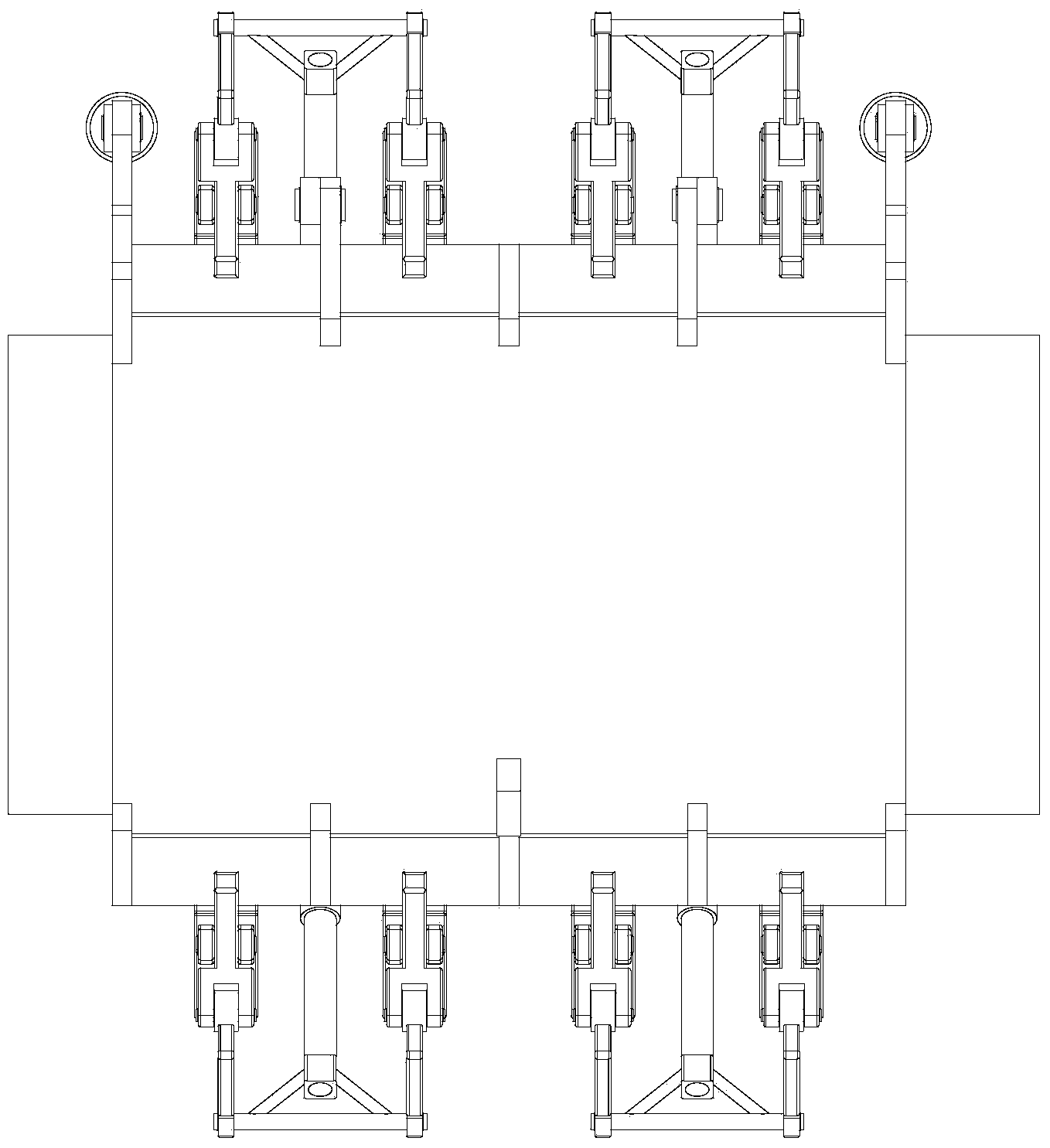

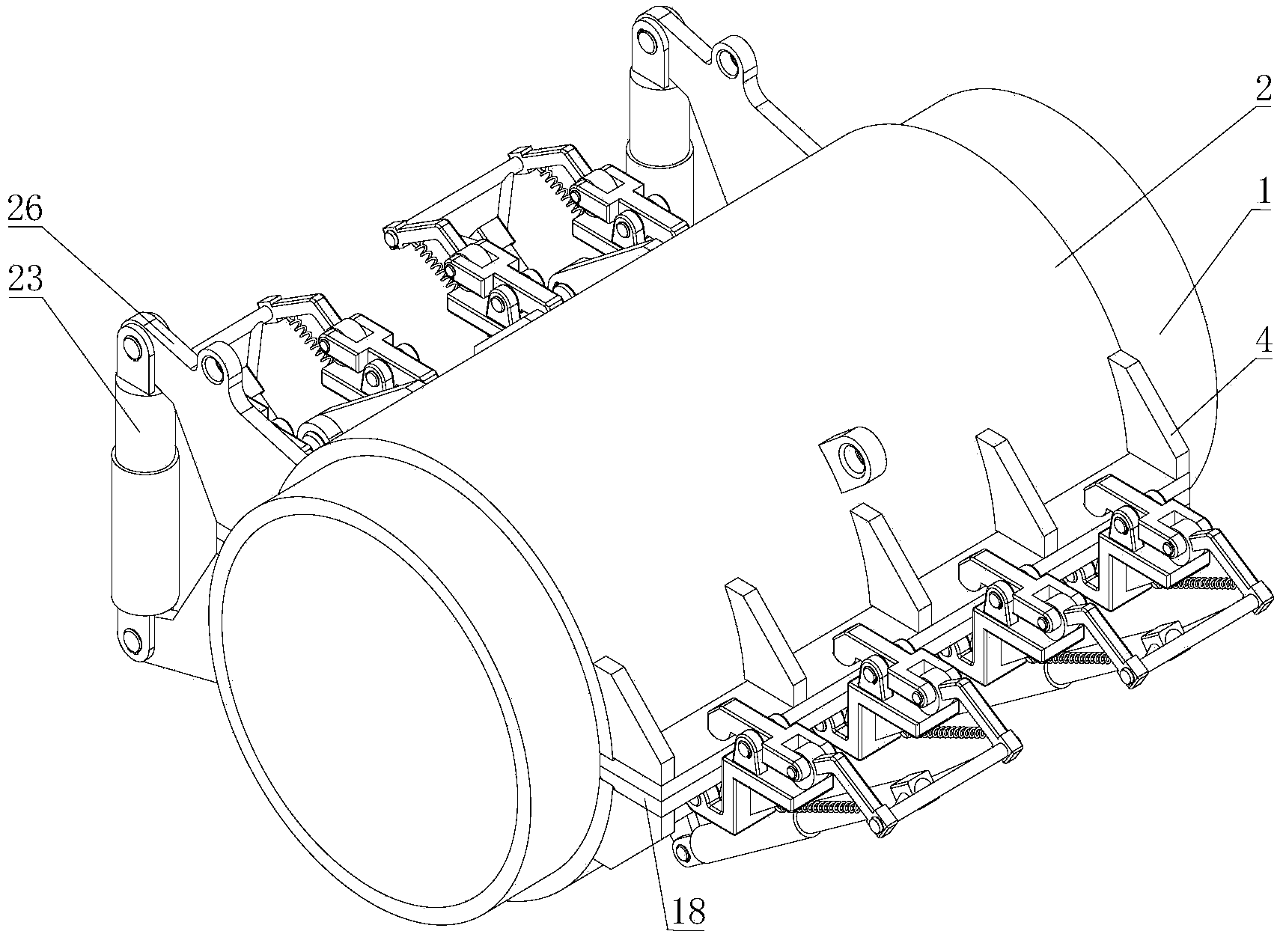

[0020] A fully automatic clamp for the repair of a submarine jacket consists of a jacket 1, a saddle plate 2, a lifting lug 3, a reinforcing rib 4, a compression lever 5, a lever support seat 6, a lever pin 7, a locking cam pin 8, Locking cam 9, spring 10, push rod 11, connecting rod 12, buckle plate 13, buckle plate reinforcement rib 14, limit block 15, buckle plate pin 16, buckle plate base 17, side plate 18, compression hydraulic cylinder pin 19. Compression hydraulic cylinder base 20, compression hydraulic cylinder 21, closed hydraulic cylinder pin 22, closed hydraulic cylinder 23, rotary shaft 24, connecting shaft reinforcing rib 25, connecting closing hydraulic cylinder reinforcing rib 26 and each pin retaining ring .

[0021] The saddle plate 2, the side plate 18, the reinforcing rib 4 and the connecting hydraulic cylinder reinforcing rib 26 are welded to form the clamp main body. The lifting lug 3 is welded on the saddle plate 2 for hoisting of the overall clamp and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com