Automatic nut and screw assembling mechanism

An automatic assembly and screw technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to adjust the position of the mechanism in the X-axis direction and Z-axis direction, limit the use range, and time-consuming and labor-intensive assembly. Simple, efficient, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

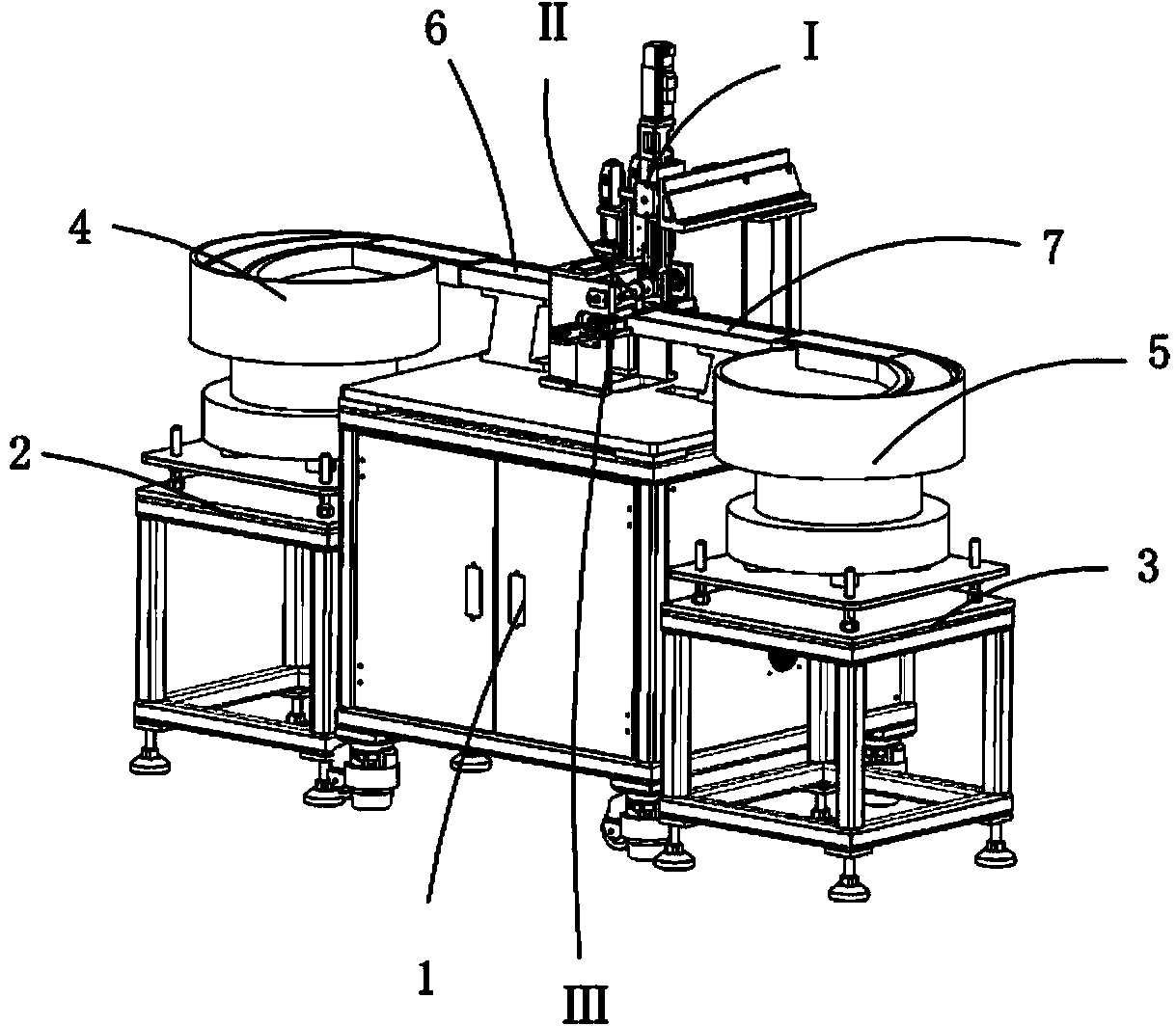

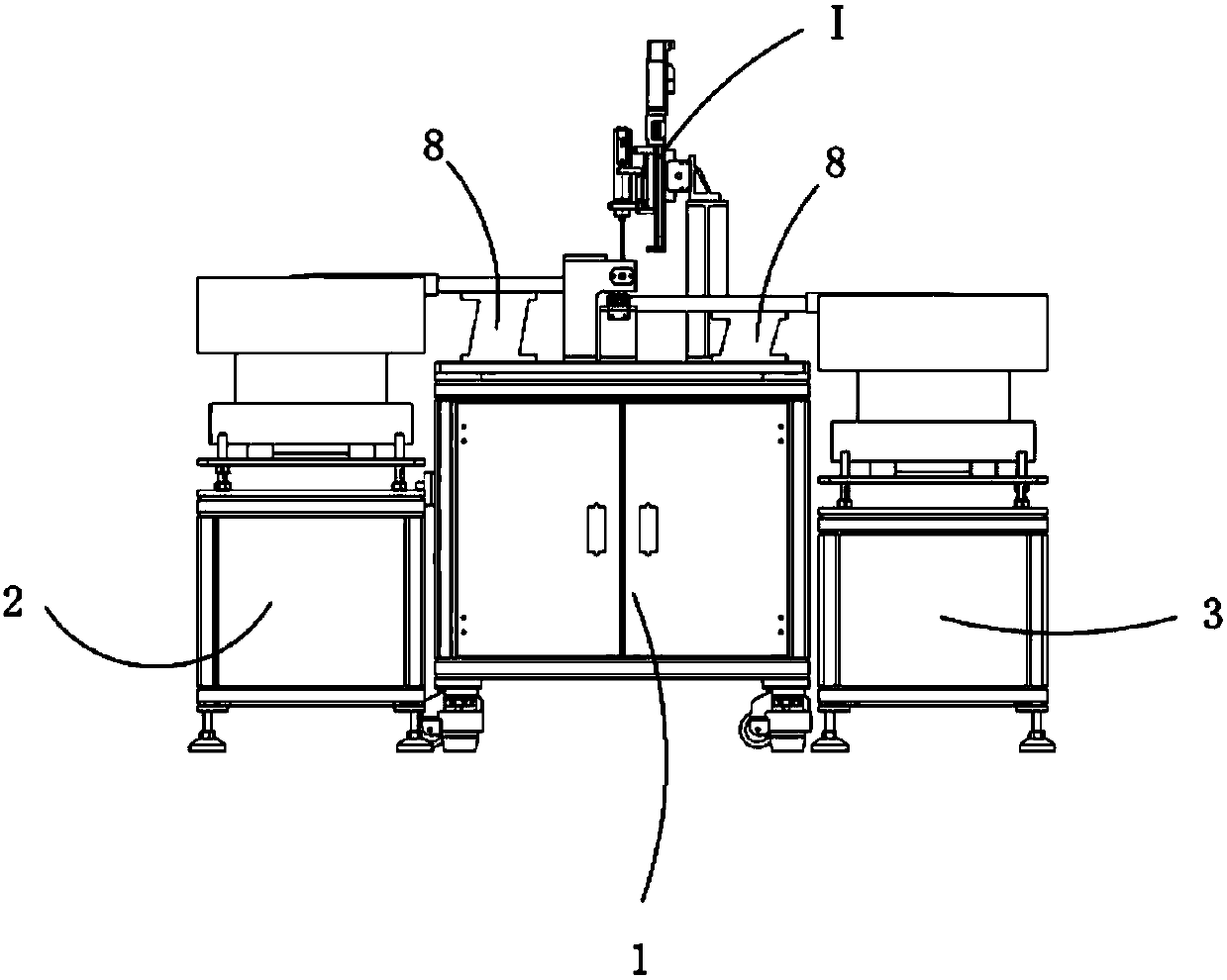

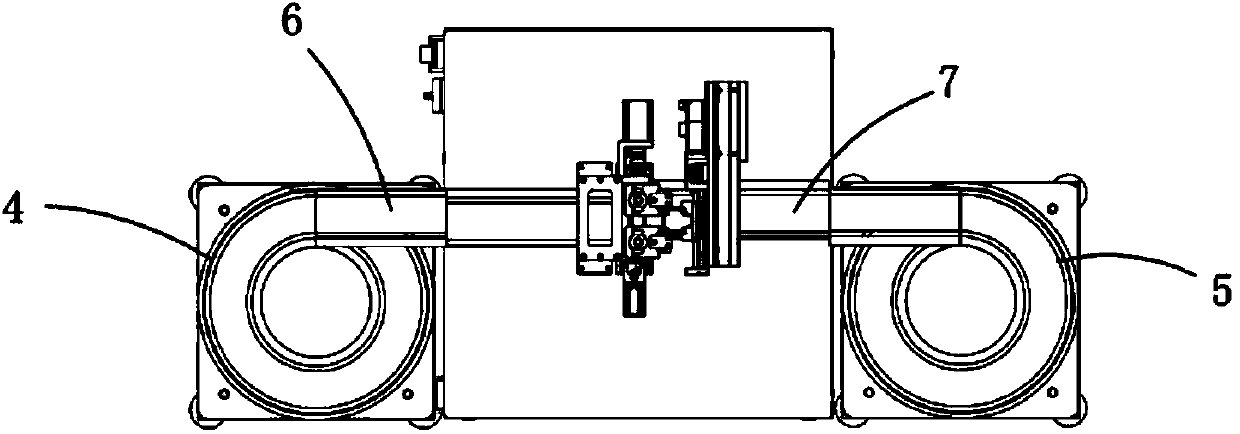

[0030] Examples, see attached Figure 1-8 , an automatic assembly mechanism for nuts and screws, which includes a chassis 1, a left vibrating plate lower frame 2, a right vibrating plate lower frame 3, a left vibrating plate 4, a right vibrating plate 5, a left direct vibrating plate 6, a right direct vibrating plate 7, Locking mechanism I, rotating material distributing mechanism II and material distributing and blanking mechanism III. The material mechanism and the material distribution and blanking mechanism, the left vibration plate is installed on the lower frame of the left vibration plate, the left vibration plate is connected with the left direct vibration, the front end of the left direct vibration is connected with the material distribution shaft of the rotary material distribution mechanism connected; the right vibration plate is installed on the lower frame of the right vibration plate, and the right vibration plate is connected with the right direct vibration, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com