Method for treating acidic heavy metal wastewater and recycling treated wastewater

A waste water treatment and heavy metal technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of cost saving, small consumption, and high water quality elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

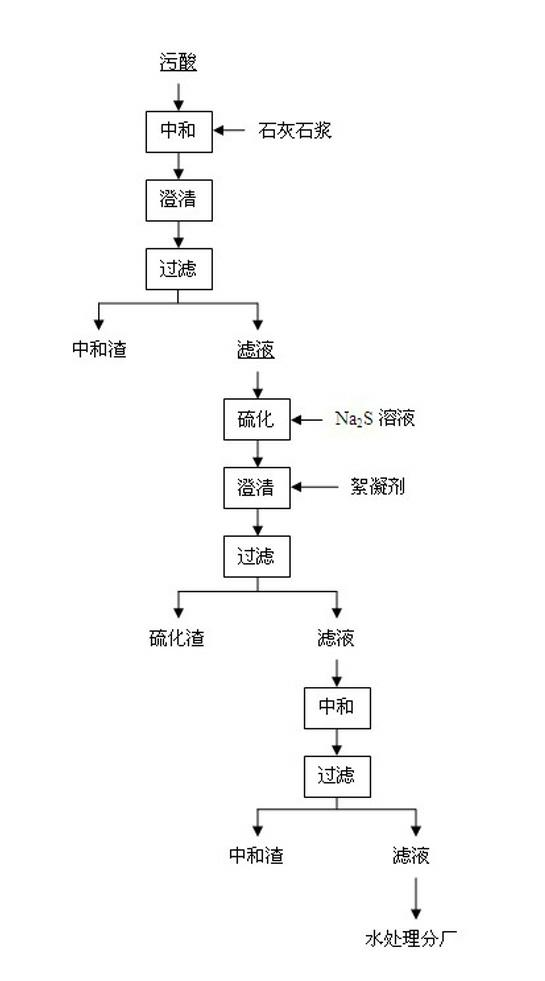

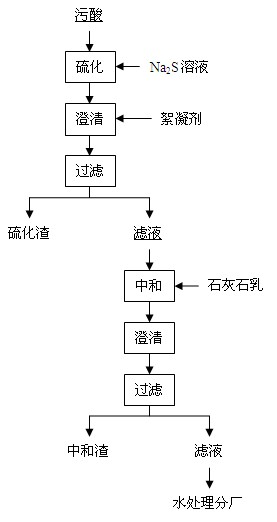

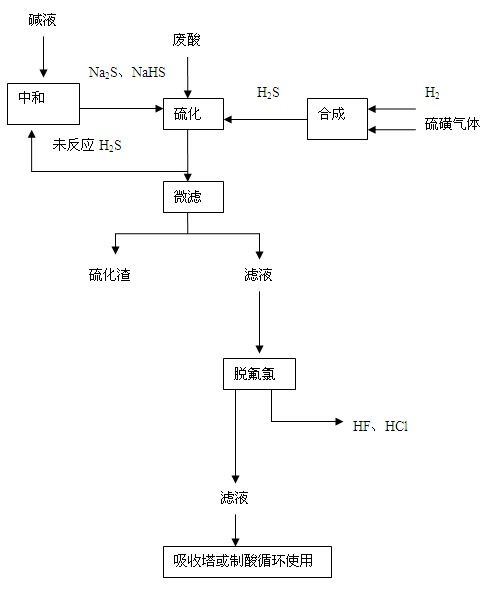

Method used

Image

Examples

Embodiment example 1

[0038] This embodiment technological process is as follows:

[0039] 1) Input the acidic waste water from the sulfuric acid purification process of smelting acid production to the absorption tower circulation tank, in which the content of copper ions is 500 mg / L, the content of zinc ions is 500 mg / L, and the content of lead ions is 200 mg / L. The arsenic content is 3500 mg / L, the chloride ion content is 1000 mg / L, and the fluoride ion content is 1000 mg / L.

[0040] 2) Hydrogen sulfide gas is formed in the mixing tower, and sulfur gas and hydrogen gas are fed into the mixing tower to make sulfur gas and hydrogen gas synthesize hydrogen sulfide gas under the pressure of 0.1-1.2Mpa;

[0041] 3) Send the hydrogen sulfide gas synthesized in step 2) into the three-stage tower tank device for circulation, and vulcanize with the waste acid aqueous solution to be treated in the three-stage tower tank device:

[0042] 4) The unreacted trace amount of hydrogen sulfide gas after step 3) i...

Embodiment example 2

[0048] The acidic wastewater to be treated in the sulfuric acid purification process of smelting acid production is input into the circulation tank of the absorption tower, in which the content of copper ions is 300 mg / L, the content of zinc ions is 300 mg / L, the content of lead ions is 100 mg / L, and the content of arsenic is 1200 mg / L, the content of chloride ion is 300 mg / L, and the content of fluoride ion is 300 mg / L. The subsequent steps are the same as in Example 1. After analysis, the filtered filtrate contains copper, zinc, lead, and arsenic each ≤0.05 mg / L L, that is, the vulcanization efficiency is ≥99.8%, the chloride ion and the fluoride ion are each ≤0.5 mg / L, and the removal effect of fluorine and chlorine is ≥95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com