Full-automatic steel-bead butt welder

A fully automatic, butt welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficulty in ensuring product consistency and pass rate, inability to fully automate, and low production efficiency. Improve production efficiency and quality, easy operation, and the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

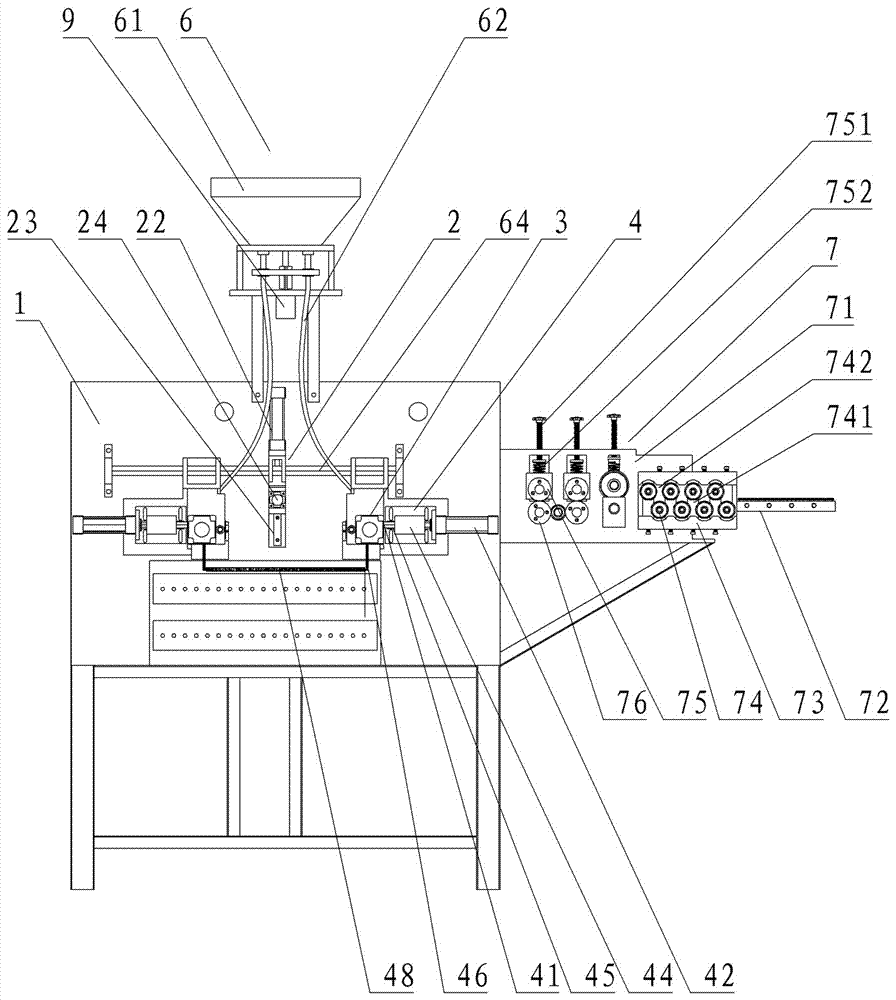

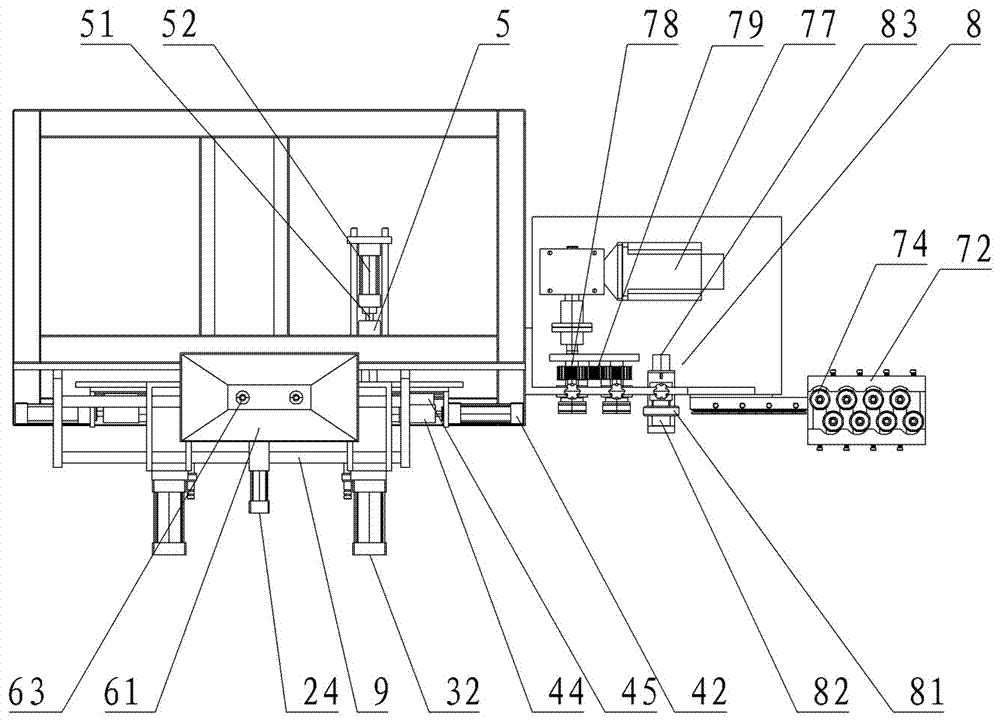

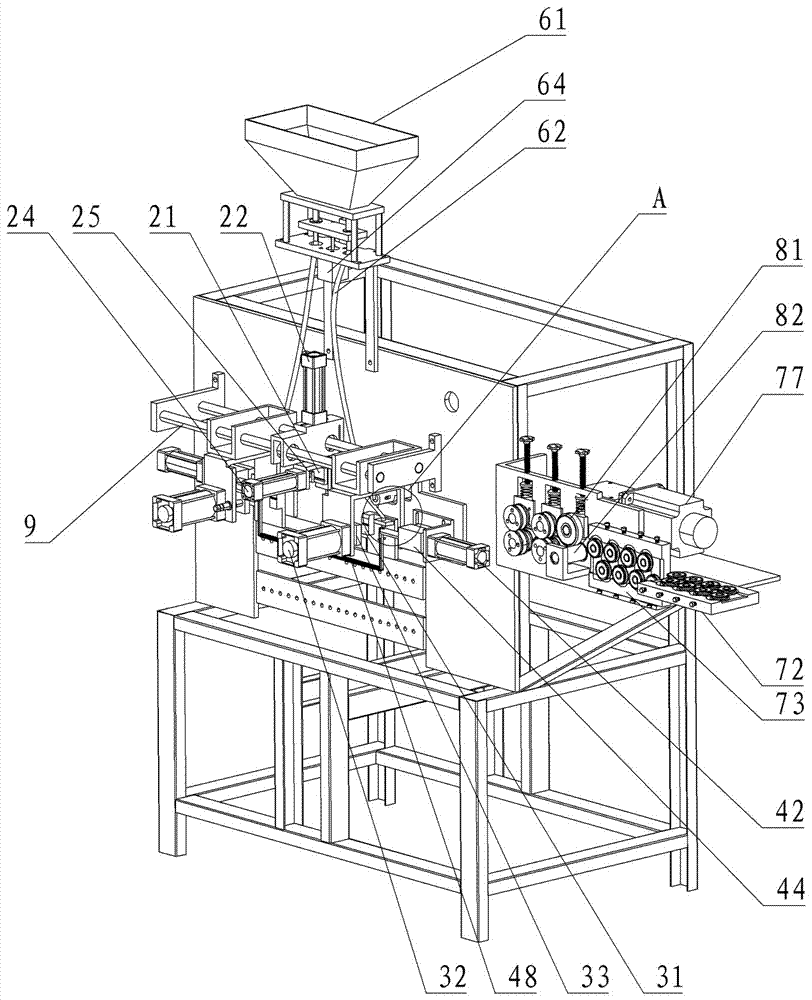

[0024] Such as Figure 1 to Figure 3 As shown, the fully automatic steel ball butt welding machine includes a frame 1. The frame 1 is at least provided with a clamping mechanism 2, a welding mechanism and a thread cutting mechanism. At least one side of the clamping mechanism is provided with a welding mechanism. The welding mechanism is at least composed of an electrode The wire clamping assembly 3 and the electrode clamping bead assembly 4 are composed of the electrode clamping bead assembly 4, which is horizontally arranged on one side of the electrode clamping assembly 3; Cutting iron wire; at the same time, through the installation of wire clamping mechanism 2 and welding mechanism, it realizes accurate clamping of iron wire and steel balls and fast and accurate butt welding, which replaces manual cutting and butt welding process, and improves production efficiency and quality. The cost of consumables and labor costs are reduced, the operation is easier, and it is more su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com