Drill clamp for connecting rod rest of needle core bed

A technology of connecting rod frame and drilling jig, which is used in clamping, manufacturing tools, and drilling dies for workpieces, etc., can solve the problem that the connecting rod frame of the needle bed cannot be accurately machined holes, etc., and achieve stable positioning and improve production. The effect of efficiency and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

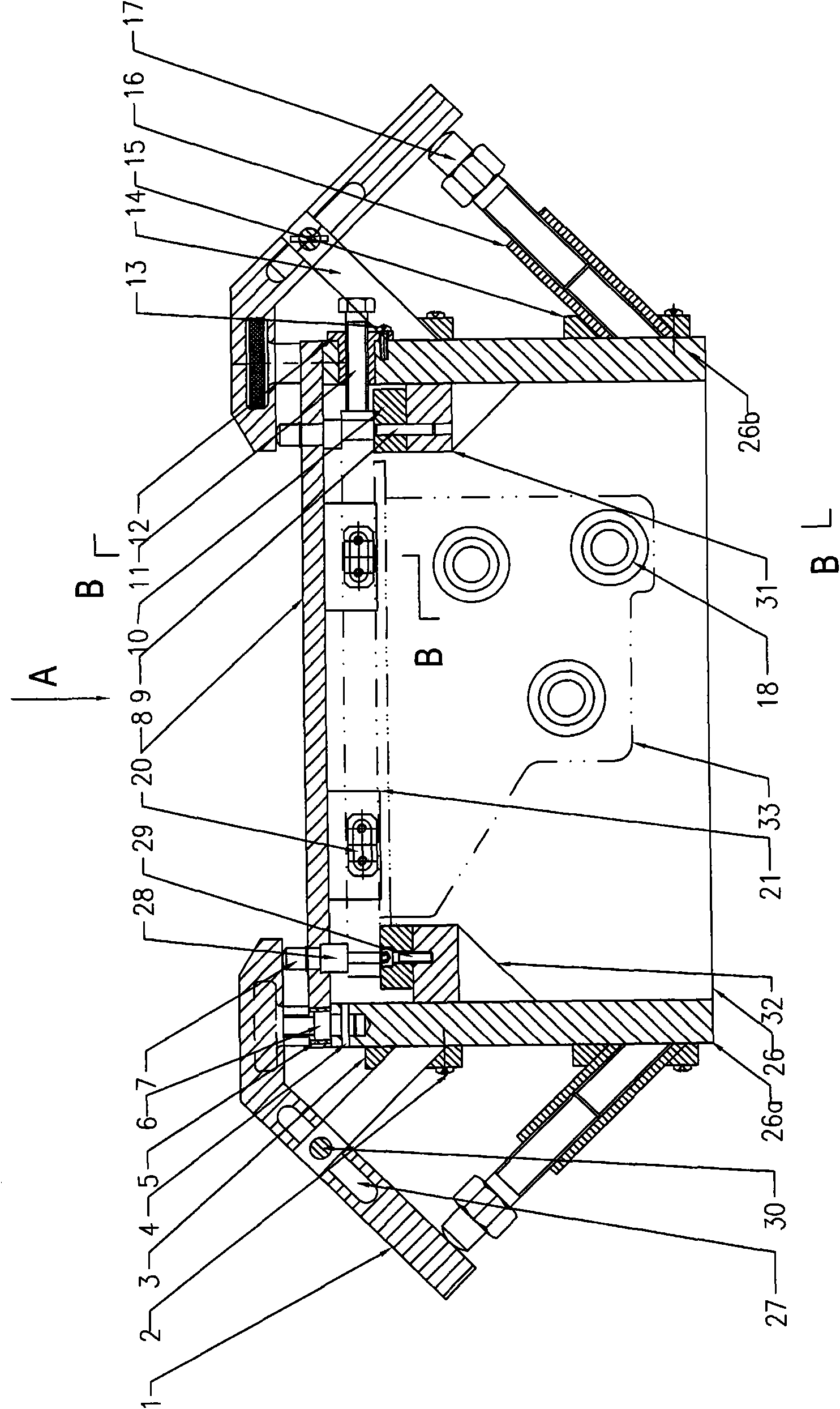

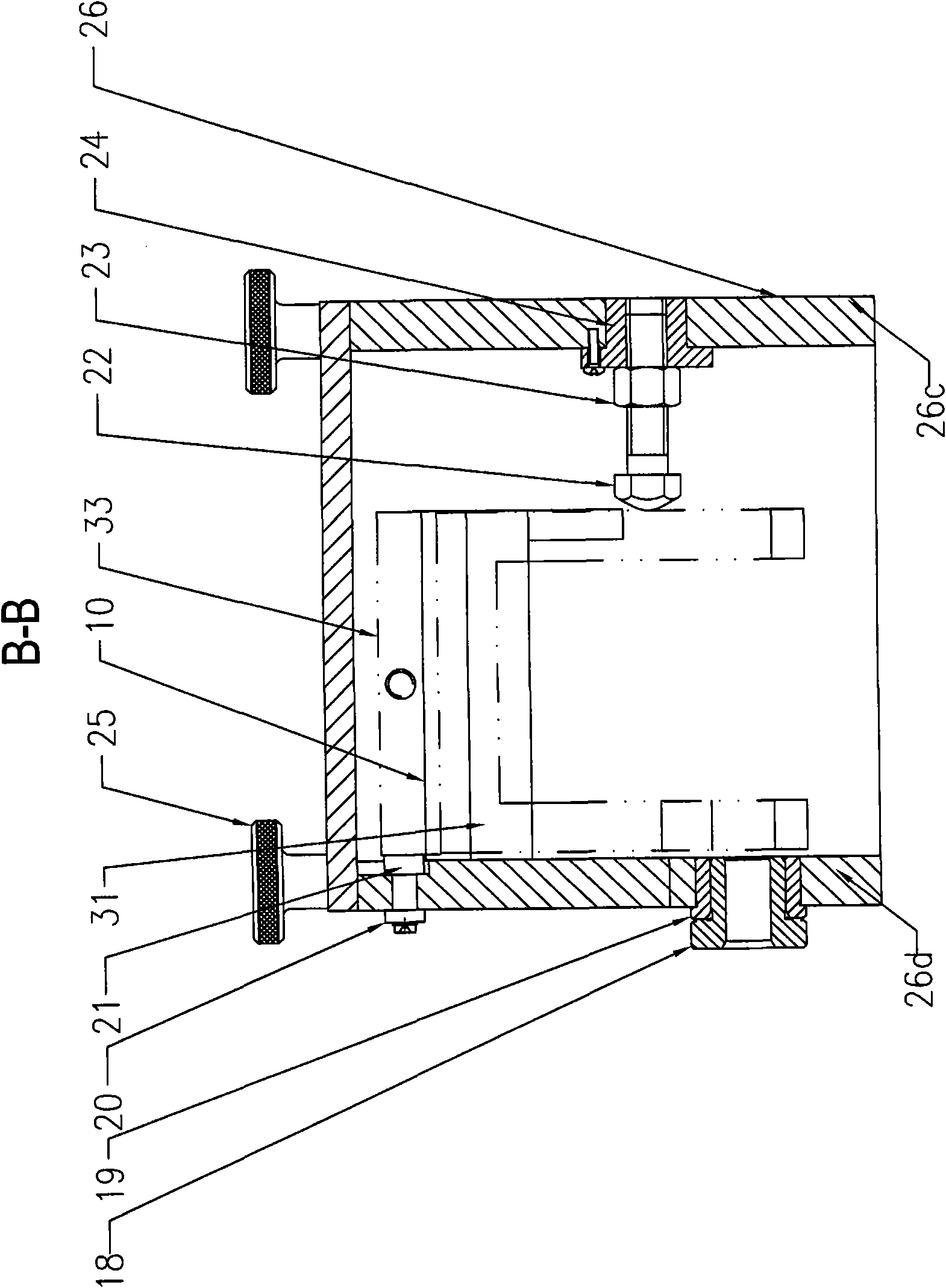

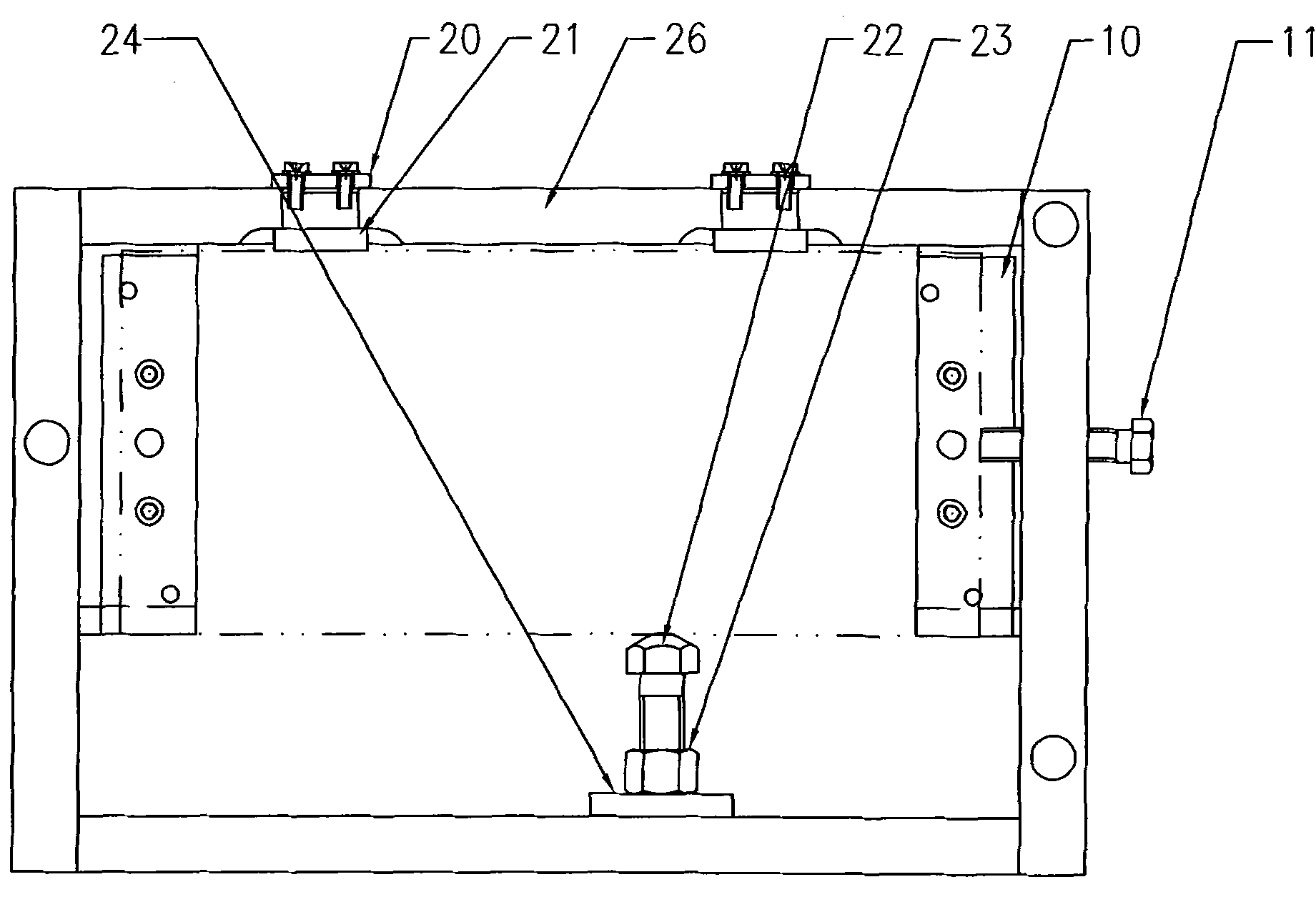

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the needle core bed connecting rod frame drilling jig is a fixture used for processing the holes of the needle core bed connecting rod frame on a drilling machine. It mainly includes a rectangular parallelepiped main body 26 with one end open, and the opening is in any direction of the main body 26. When the core bed connecting rod frame enters the main body 26, the opening is in the upward direction of the main body 26, and its surroundings are divided into two side surfaces 26a, 26b, a main surface 26c, and a back surface 26d. The main body 26 is provided with a top plate 31, and the top plate 31 has two Block, it is elongated shape, and two top plates 31 are respectively arranged on the side 26a of main body 26 and side 26b, and under the top plate 31 and between the side 26a of main body 26 and side 26b, be respectively provided with triangular rib plate 32, support plate There are also two pieces of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com