Automatic tube-inversing and loading device of tube bending machine and using method of automatic tube-inversing and loading device

A technology of automatic turning and bending machine, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of safety accident, low efficiency, time-consuming and laborious, etc., and achieve the effect of improving production efficiency and improving feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

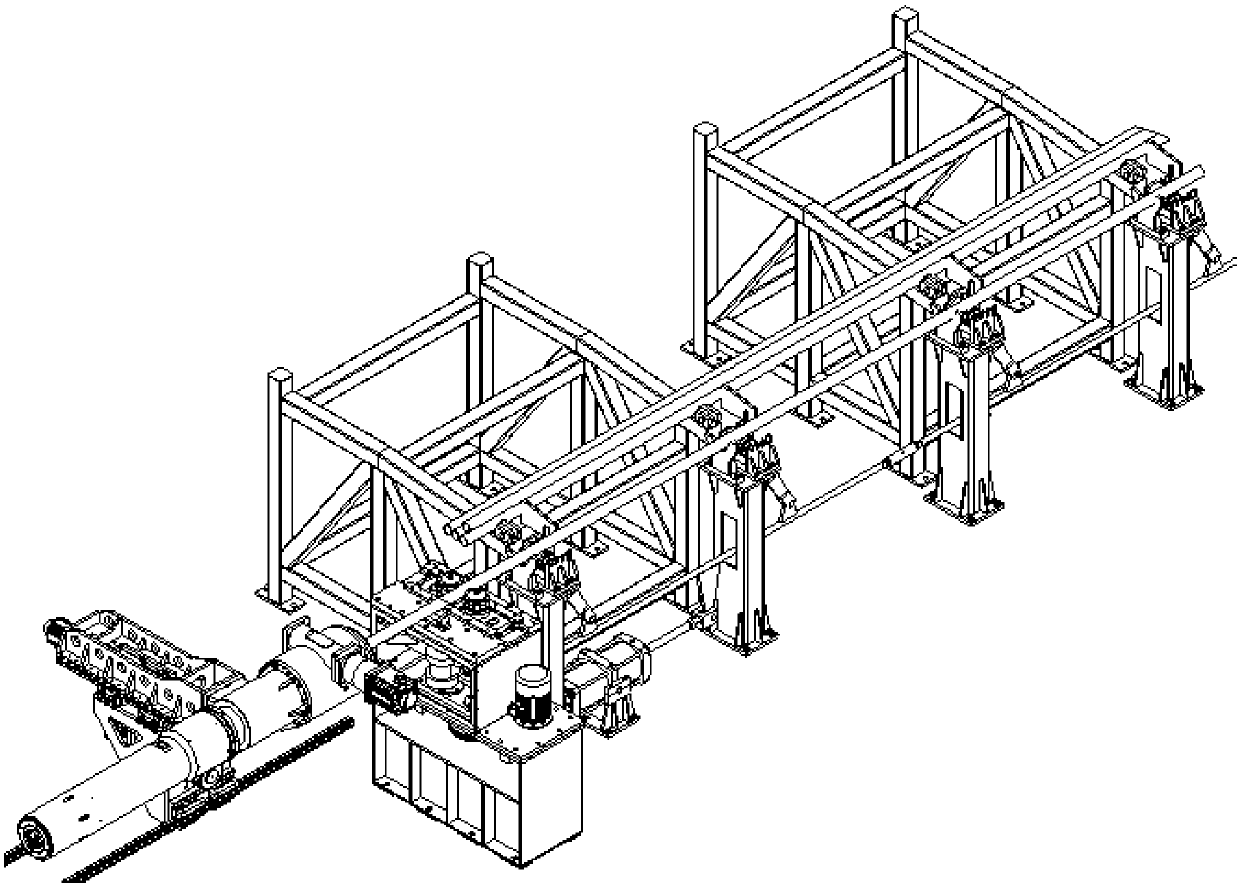

[0060] Such as figure 1 As shown, this embodiment provides a pipe bending machine, which is mainly composed of a worktable, a pipe bending die, a flexible feeding device, a feeding push device, and an automatic pipe turning and feeding device, wherein the workbench and the pipe bending die are The common parts in the existing industry are not shown in the figure. Both the flexible feeding device and the pipe bending die are set on the workbench. The flexible feeding device is used to clamp the pipe to be bent and send it to the pipe bending die for bending operation ; while the automatic pipe turning and feeding device is used to place the pipes to be bent in batches, and prepare the feeding of the pipes to be bent one by one, and transfer the pipe fittings to the feeding pushing device, and then the feeding pushing device will further send the pipe fittings to the flexible feeding device, Complete the loading operation. Through the cooperative operation of the above-mentione...

Embodiment 2

[0068]In this embodiment, on the basis of Embodiment 1, the structure of the feeding and pushing device of the pipe bender is optimized to solve the problem of time-consuming, labor-intensive and labor-intensive alignment of the pipe material and insertion into the clamping part 1 of the existing pipe bender. , Low efficiency and other issues. The feeding and pushing device of the pipe bender in this embodiment mainly includes a shell frame, a wheel rotation driving part 8, a roller translation driving part 9 and a roller clamping part 10; A pair of rollers 1020 above the shell frame; the roller rotation drive part 8 is used to drive a pair of rollers 1020 to rotate synchronously; the roller translation drive part 9 is used to drive a pair of roller slides 1010 to approach or move away, so that a pair of rollers 1020 clamp Tighten or loosen the pipe to be bent.

[0069] For the province of material feeding, it is not difficult. There are also many structures in the prior art....

Embodiment 3

[0081] Although Embodiment 2 has well solved the problem of aligning and sending the pipe material into the clamping part 1, the feeding pushing device needs to put the pipe material between a pair of rollers 1020 before conveying the pipe material. Feeding is time-consuming, labor-intensive, and inefficient. Therefore, it is undoubtedly the best way to use feeding equipment to improve manual feeding. This embodiment just provides such a device to solve the feeding problem of the feeding push device.

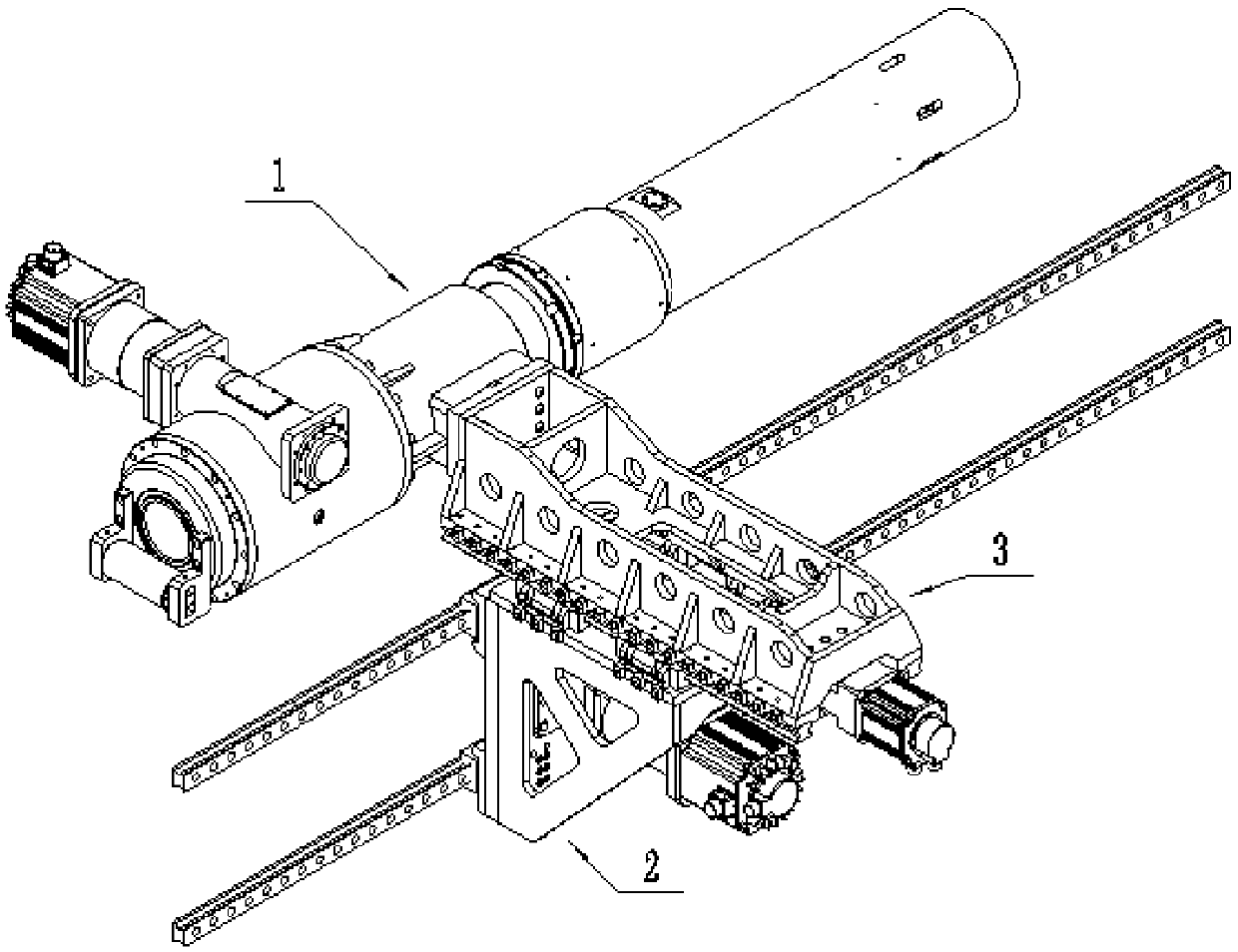

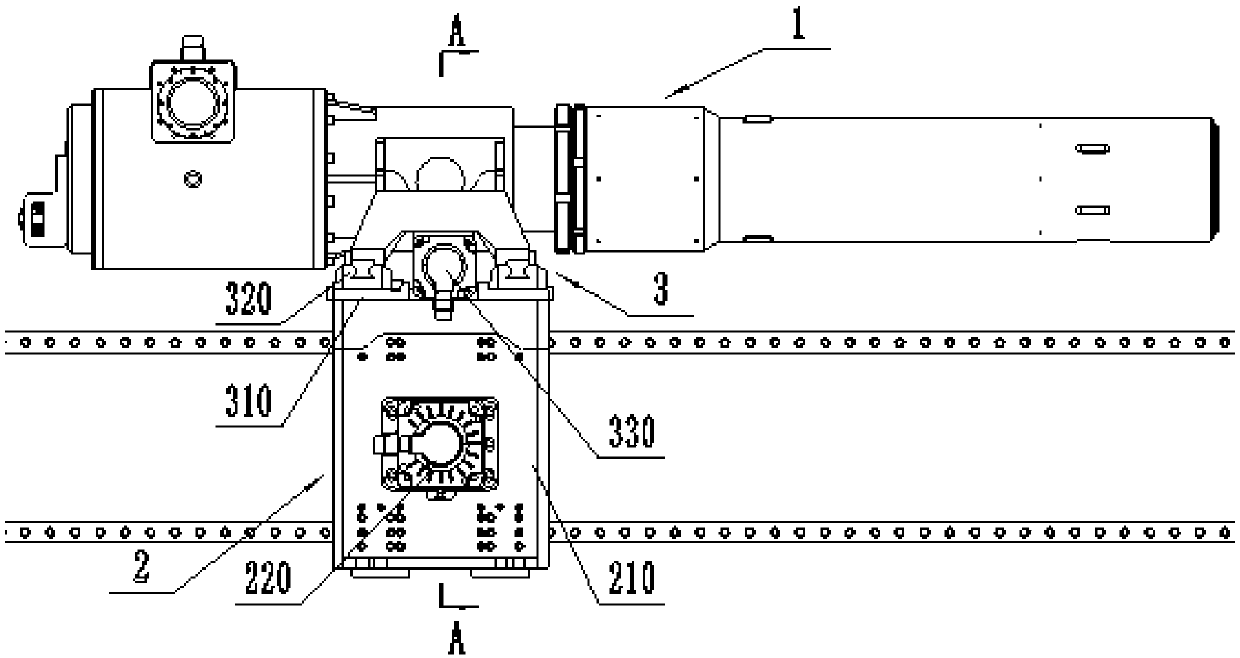

[0082] combine Figure 12 to Figure 16 As shown, this embodiment provides an automatic pipe turning and feeding device for a pipe bending machine, which mainly includes a pipe rack 4 for placing the pipe to be bent, a material supporting part 5 , a pipe turning driving part 6 and a pipe turning mechanism 7 . Wherein, the material pipe frame 4 adopts the frame welded by steel pipes to place the pipes to be bent, and has a pair of end-to-end connecting beams 410 and distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com