Device for producing complete empty eggshell

An empty eggshell and complete technology, which is applied in special decorative structures, decorative arts, household appliances, etc., can solve the problems of pinching raw eggs, difficult to locate holes, and difficult to clean empty eggshells, and achieve the effect of accurate hole piercing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

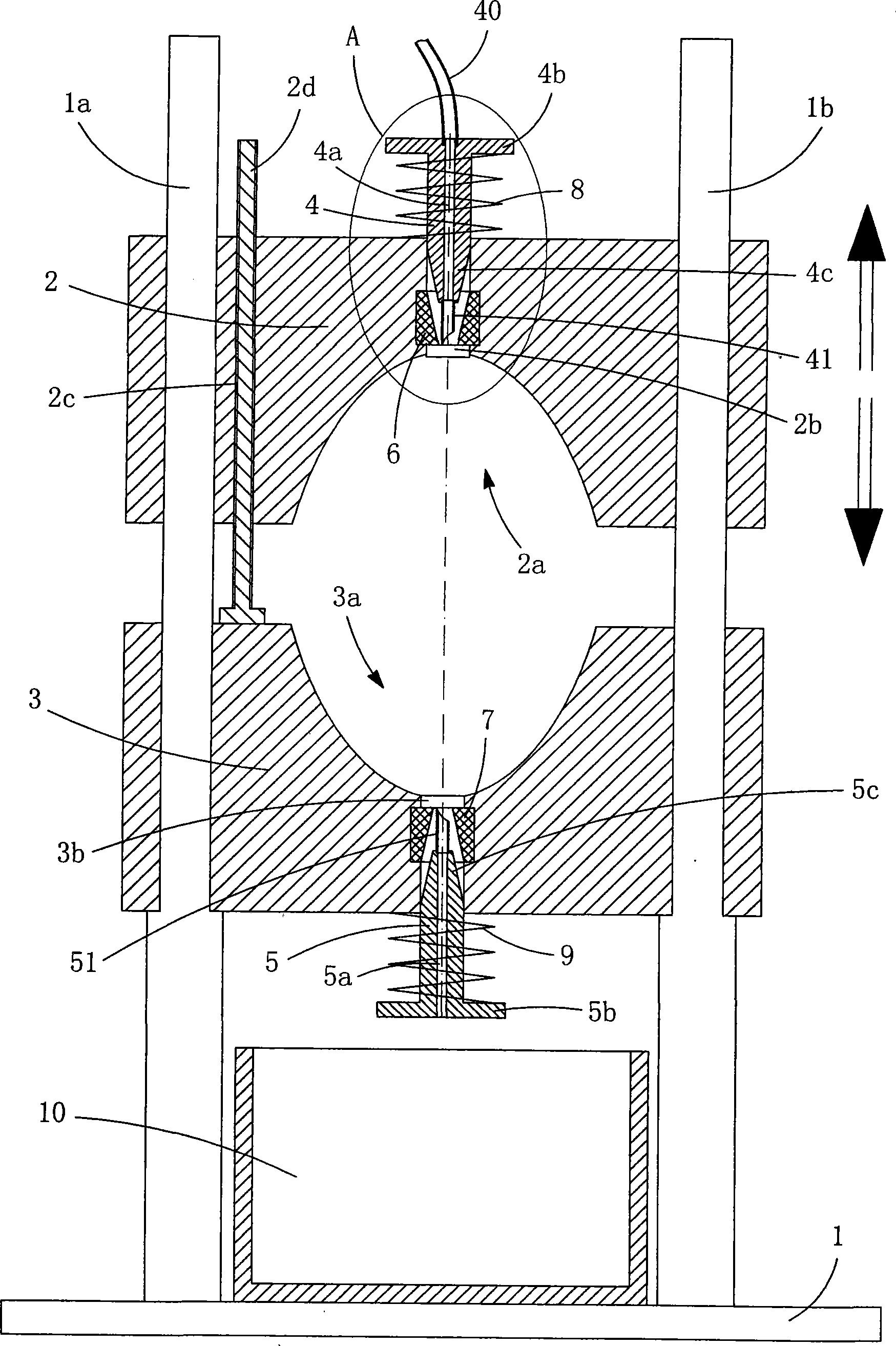

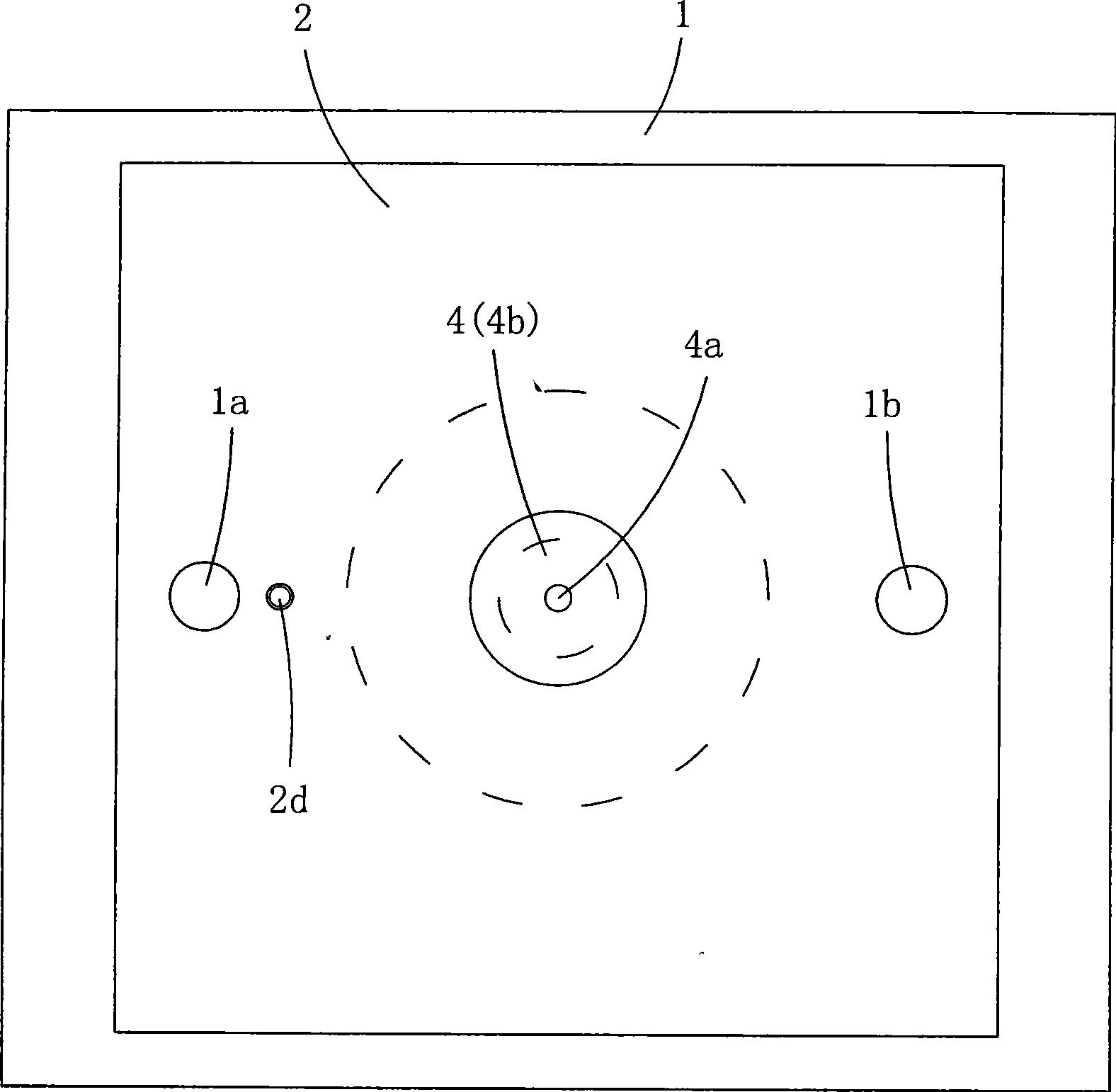

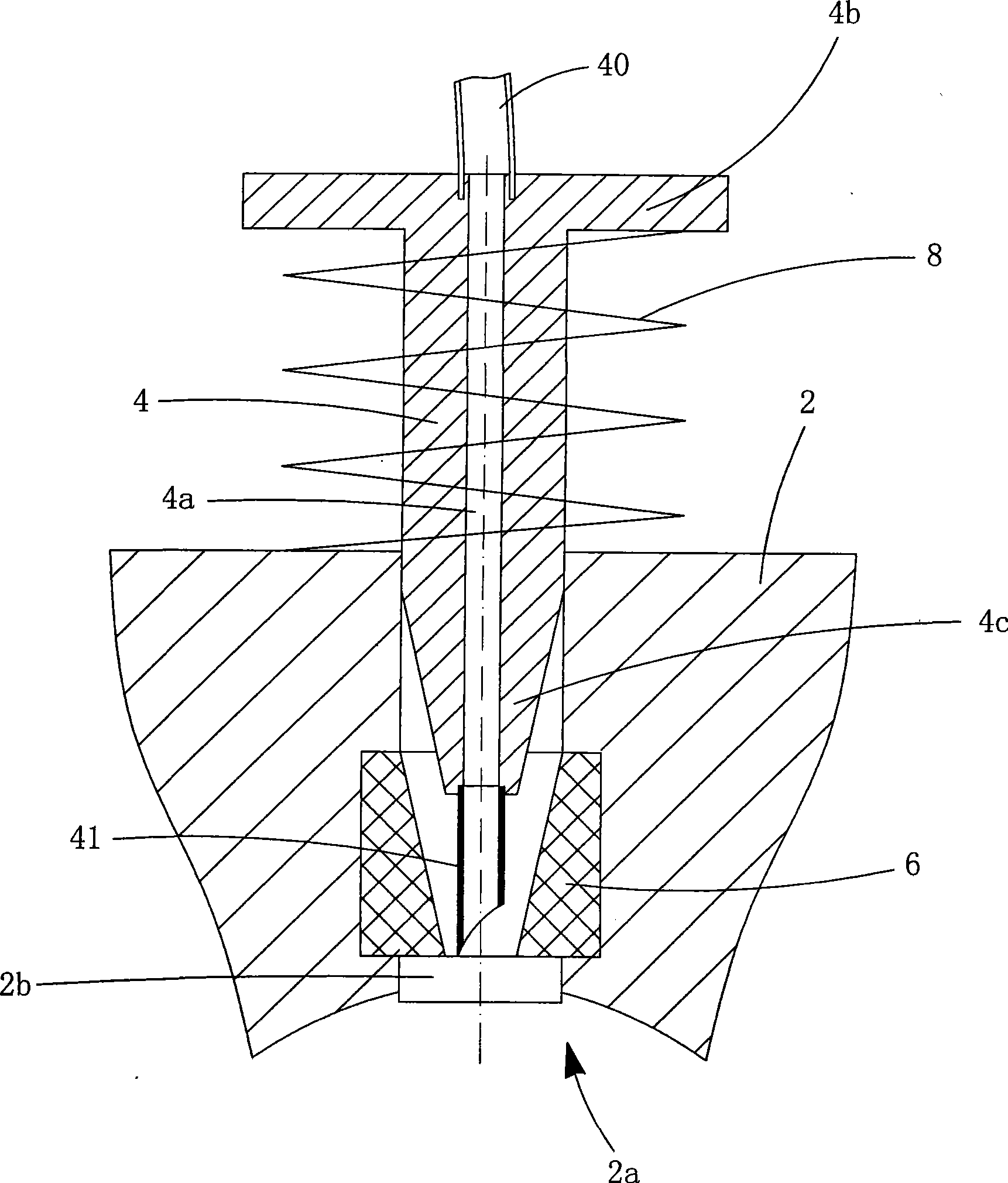

[0017] Such as figure 1 and combine figure 2 , image 3 and Figure 4 shown. A device for making complete empty eggshells, mainly comprising a horizontal base plate 1, left and right polished rod columns 1a, 1b symmetrically and vertically fixed on both sides of the top surface of the horizontal base plate 1, and corresponding devices on the upper and lower parts of the columns 1a, 1b , The lower seat body 2,3, is respectively installed on the upper and lower seat body 2,3 correspondingly plugged with the manual push rod 4,5 of the hollow needle head 41,51 of pricking holes. The vertical columns on the top surface of the horizontal base plate 1 are not limited to two, but can be arranged symmetrically as three or four columns, which will not be described in detail here.

[0018] Such as figure 1 and combine Figure 2 to Figure 4 shown. Both sides of the upper and lower bases 2, 3 are provided with longitudinal guide holes corresponding to the left and right uprights 1a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com