Tool holding structure

A clamping structure and tool technology, applied in the direction of clamping, tool manufacturing, support, etc., can solve the problems of tool holder installation orientation error, danger, etc., and achieve the effect of simple structure, improved reliability, and precise tool clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

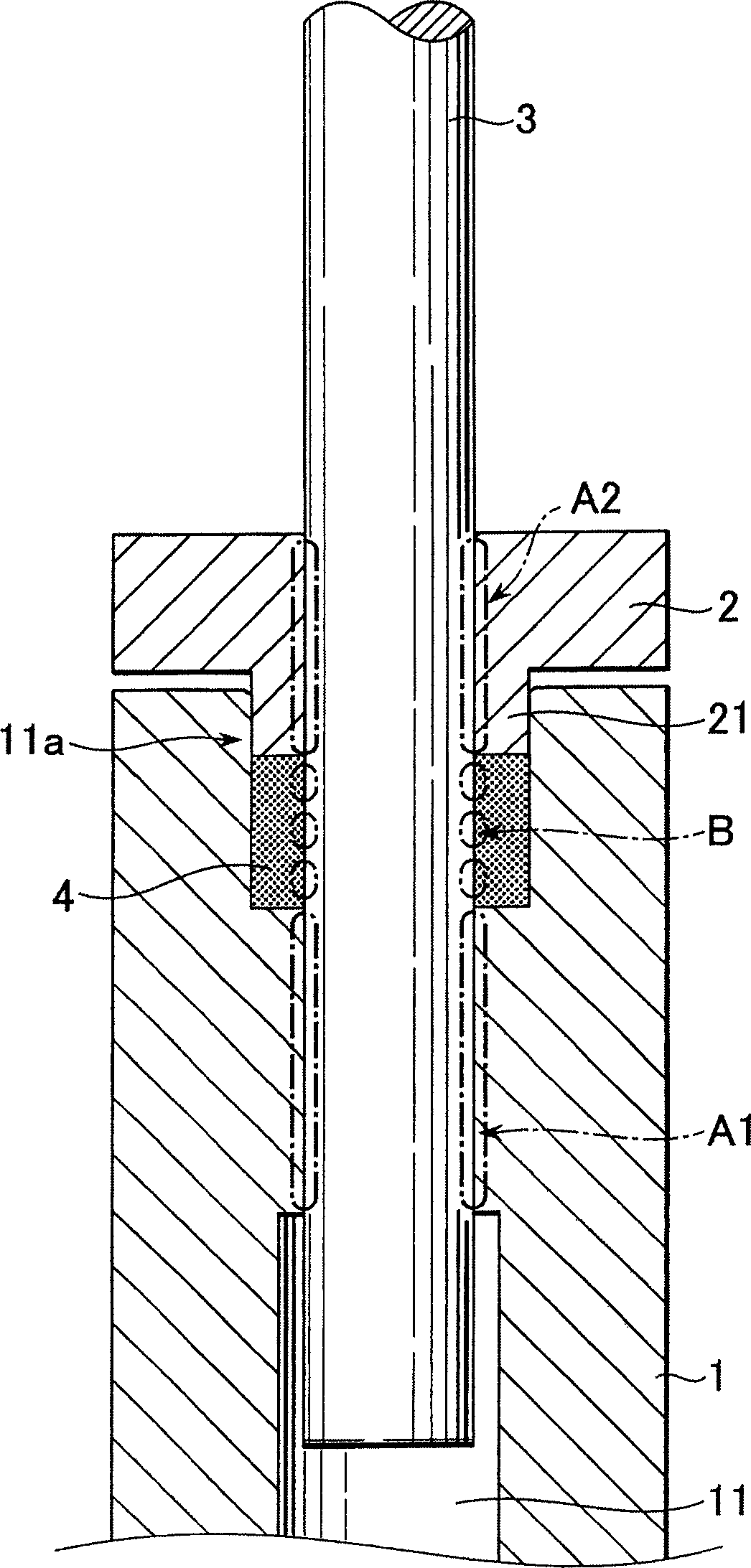

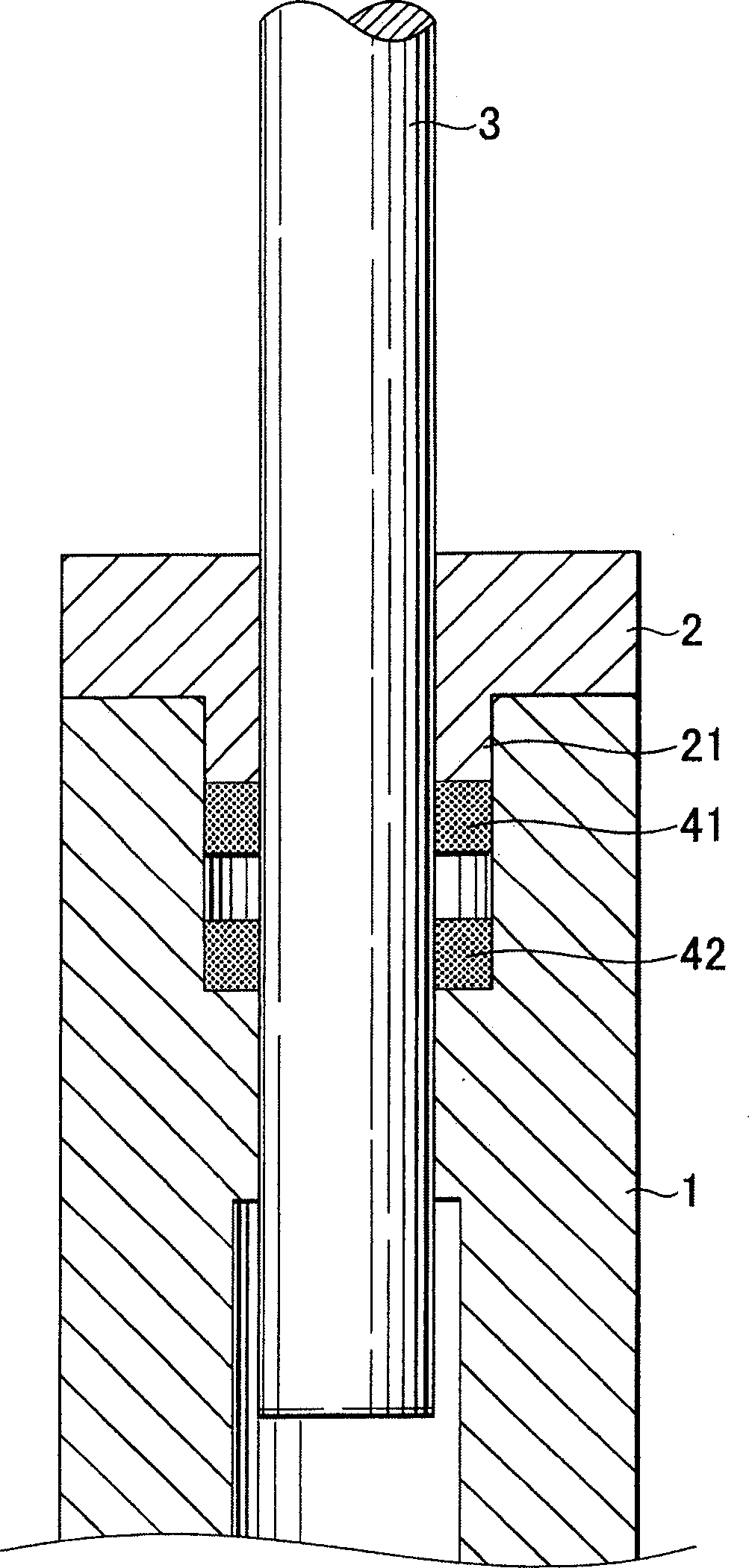

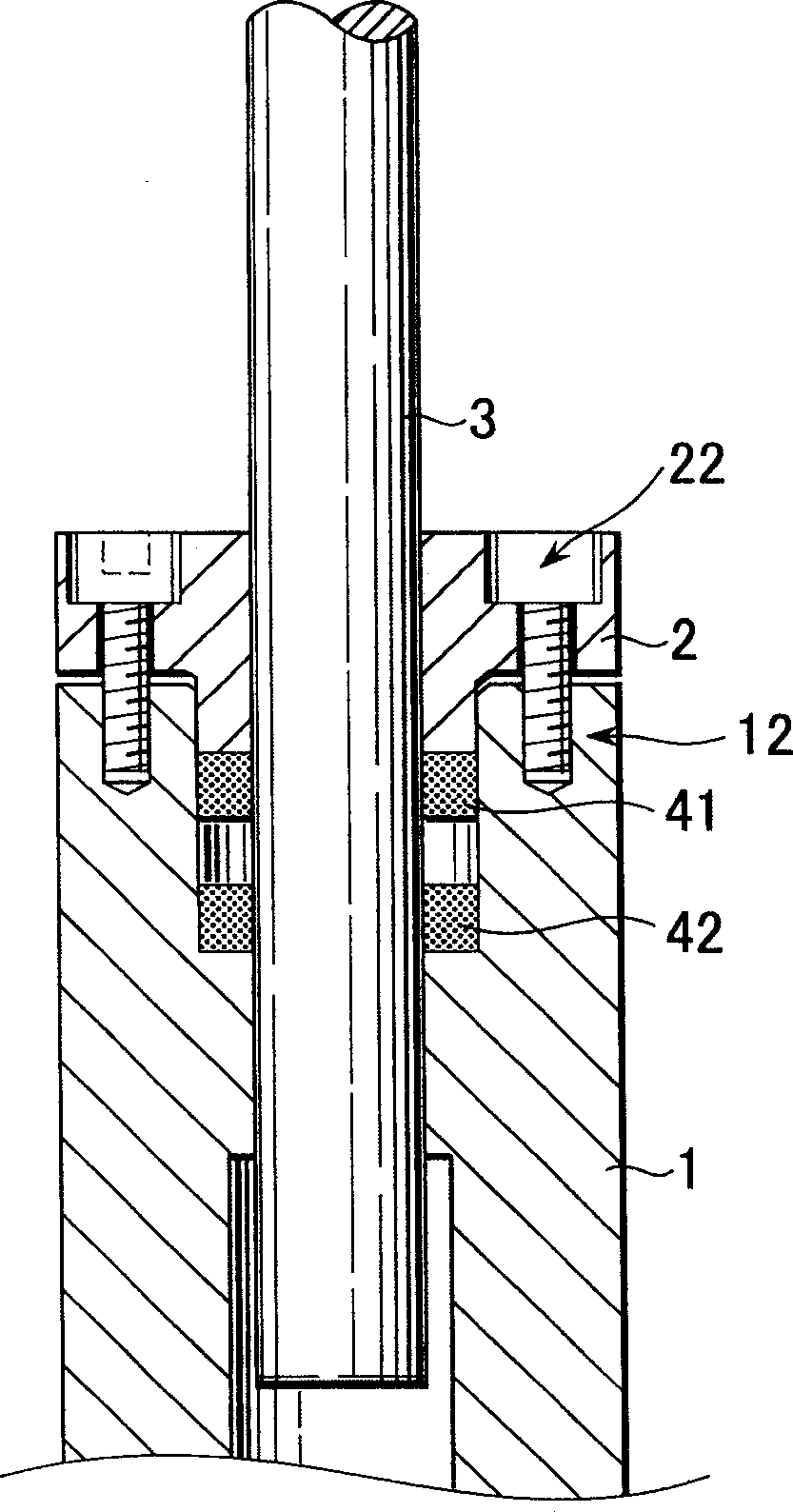

[0021] figure 1 is a sectional view showing a section along the axis of the main shaft, showing main parts of a tool holding structure according to an embodiment of the present invention. exist figure 1 In , reference numeral 1 denotes a main shaft of a machine tool, and main shaft 1 has a tool shank insertion hole 11 extending in the axial direction of main shaft 1 . Reference numeral 2 denotes a sleeve coaxially mounted on the main shaft 1 , the sleeve 2 having an insertion portion 21 inserted into a large diameter portion 11 a formed on the entry side of the shank insertion hole 11 .

[0022] Both the shape and size of the inner peripheral surface of the large-diameter portion 11a and the outer peripheral portion of the insertion portion 21 are precisely matched to each other. The sleeve 2 also has a through hole through which the tool shank 3 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com