Feeding and discharging machine tool in full-automatic machine

A technology of automatic machines and machine tools, applied in the directions of metal processing mechanical parts, clamping, support, etc., can solve the problems of inability to realize continuous loading and unloading, low efficiency, etc., and achieve the effect of saving working time and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the drawings.

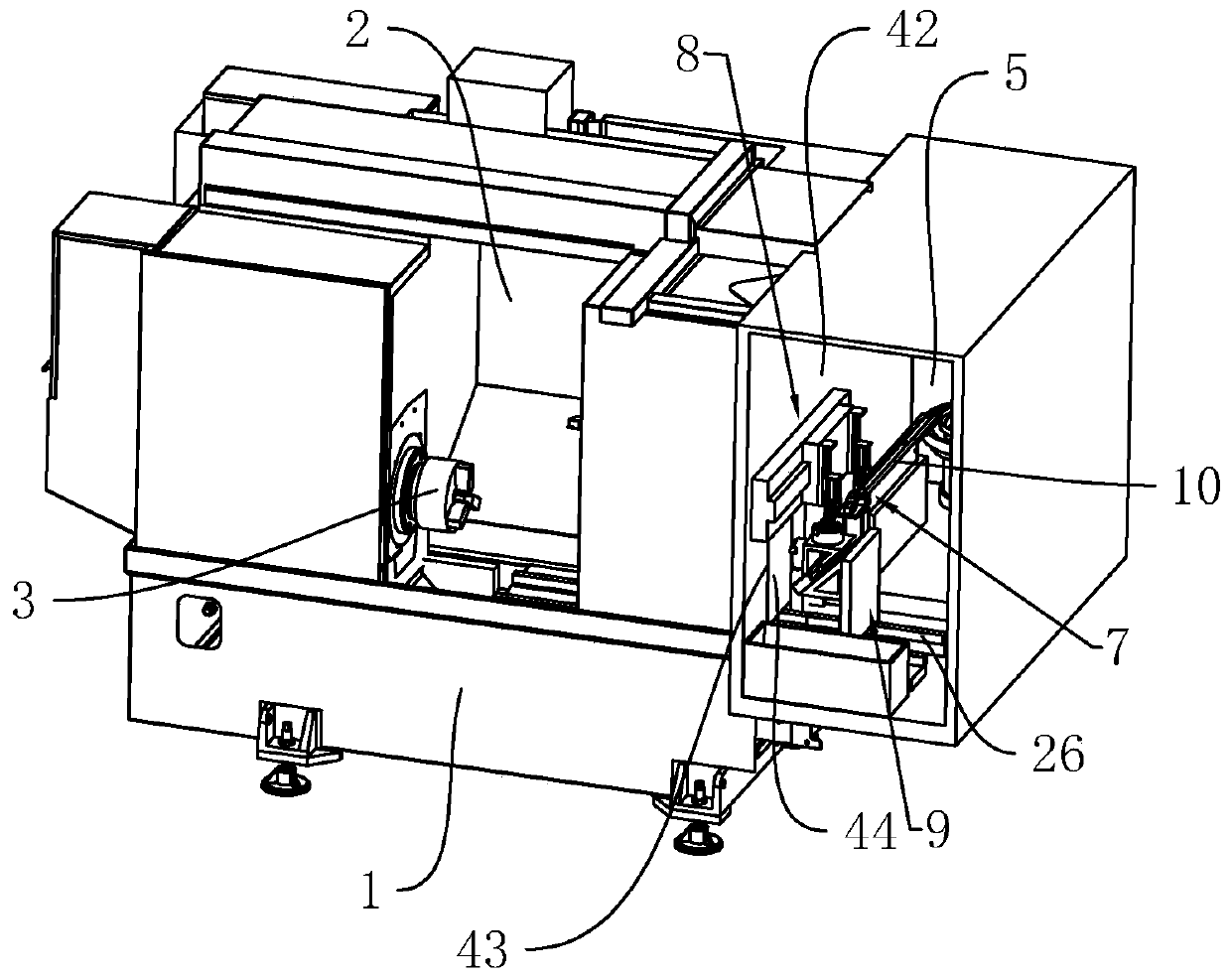

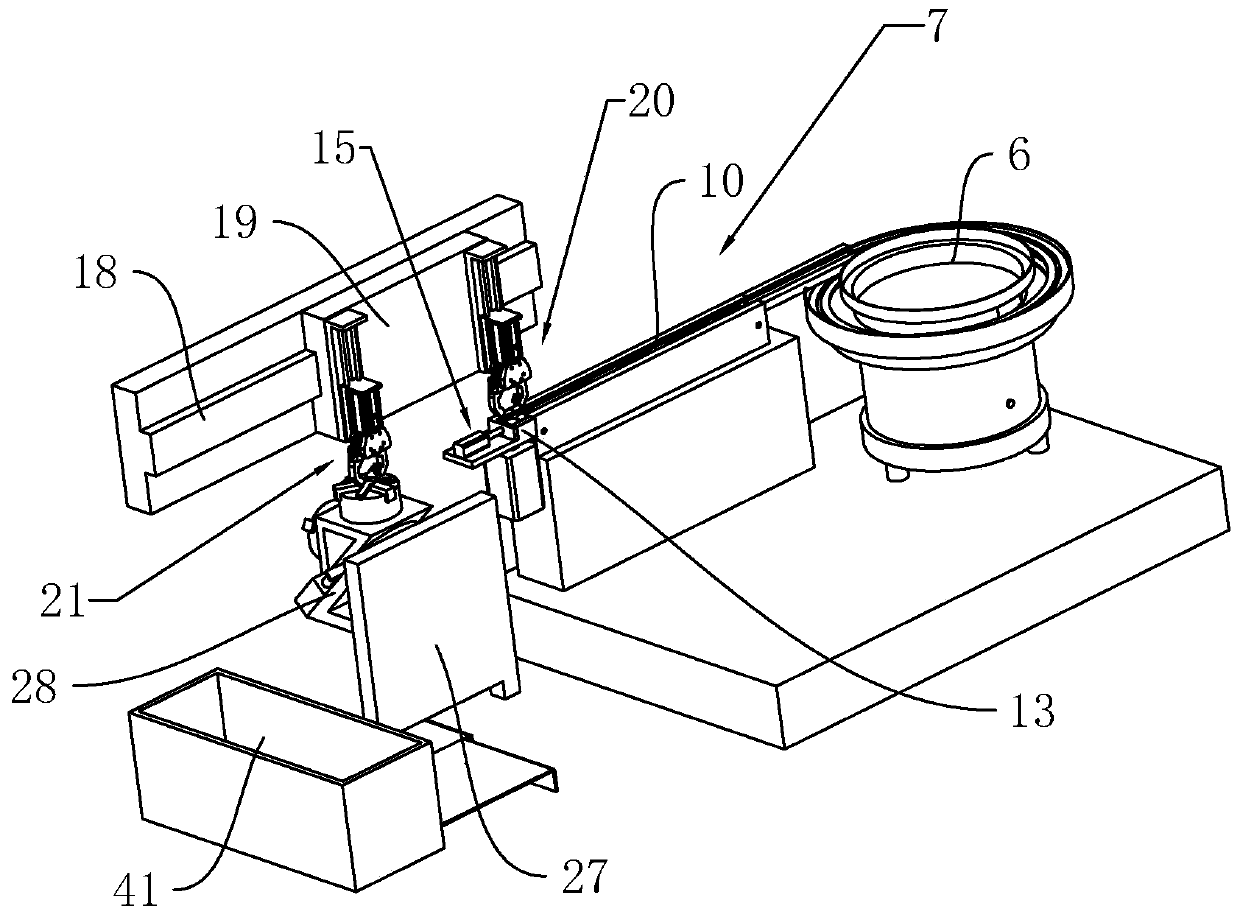

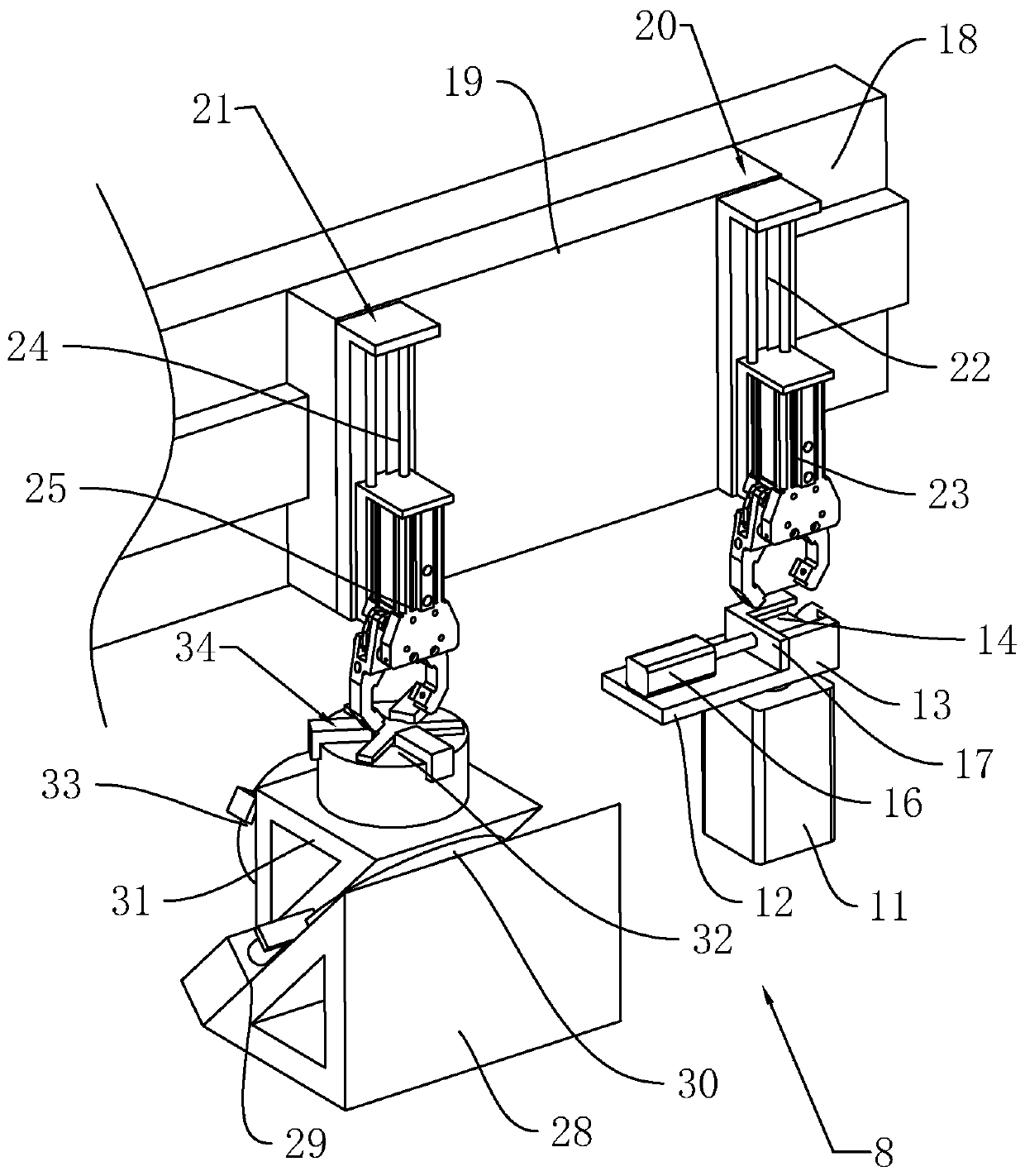

[0040] Reference figure 1 with figure 2 , Is a fully automatic machine loading and unloading machine tool disclosed in the present invention, including a bed 1 and a processing warehouse 2 arranged on the bed 1. A spindle 3 and a cutting assembly for processing workpieces are arranged in the processing warehouse 2 4. On the bed 1 and at a position on the side of the processing warehouse 2, there is a feeding silo 5 connected to the processing silo 2. A vibrating disk 6 is provided in the feeding silo 5, and the discharge end of the vibrating disk 6 is provided with a feeding end Mechanism 7, the upper end of the bed 1 is provided with a transfer assembly 8 for clamping the workpiece, and the bed 1 is provided with a feeding mechanism 9 for sliding movement on the side of the feeding mechanism 7, and the transfer assembly 8 can transfer the feeding mechanism The blank part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com