Processing clamping device for thin-walled framework and clamping method

A clamping device and frame technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the clamping method does not have the transmission of the rotational torque of the machine tool, the main coil frame cannot be processed at one time, and the outer circle of the frame is installed To avoid problems such as clamping deformation, achieve the effect of convenient clamping, avoid concentricity errors at both ends, and avoid clamping and processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

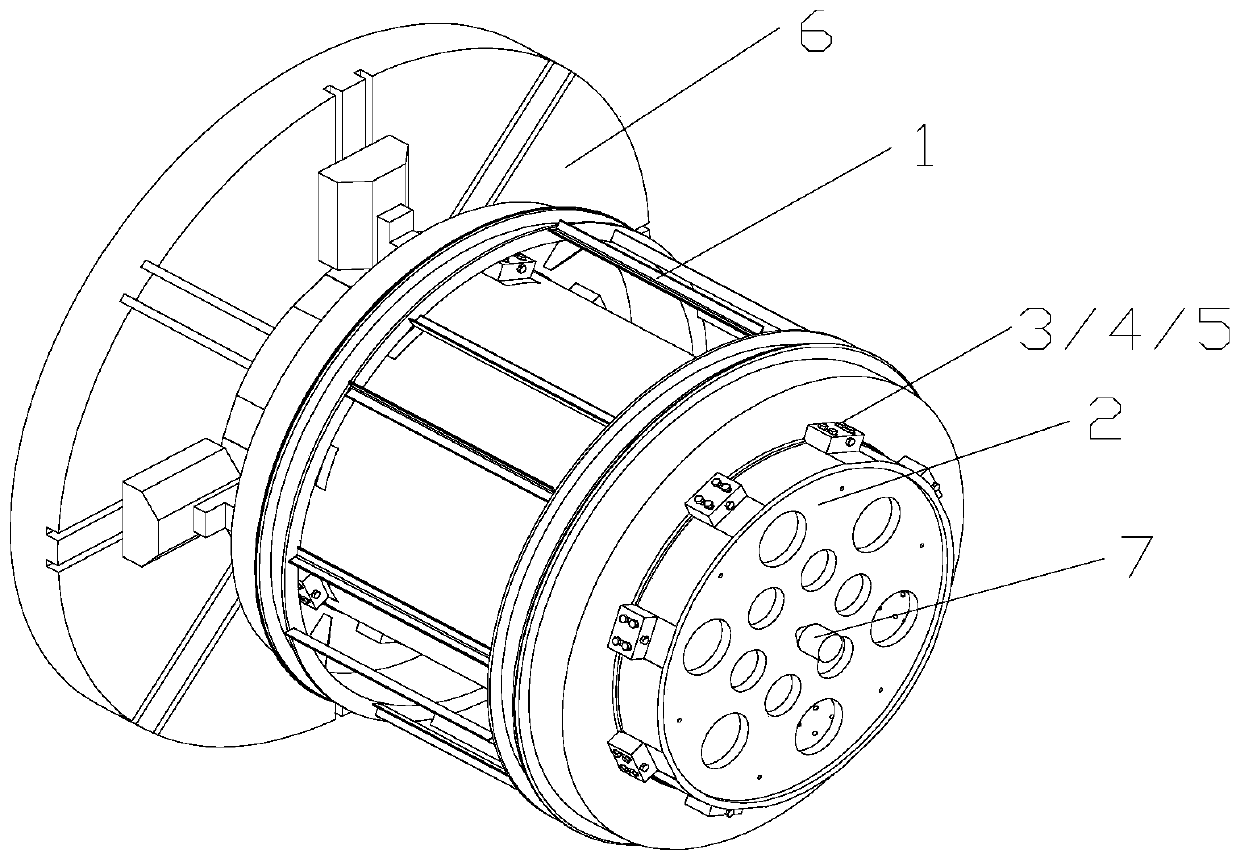

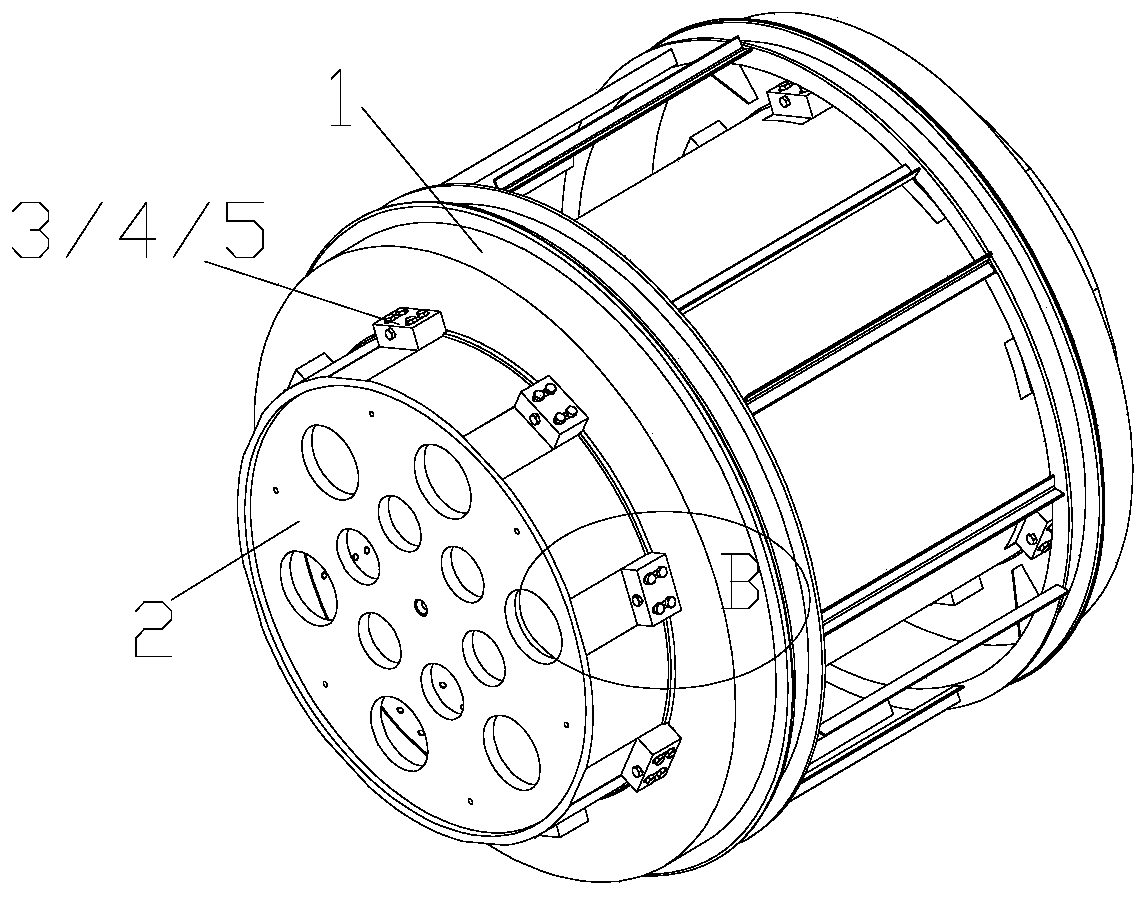

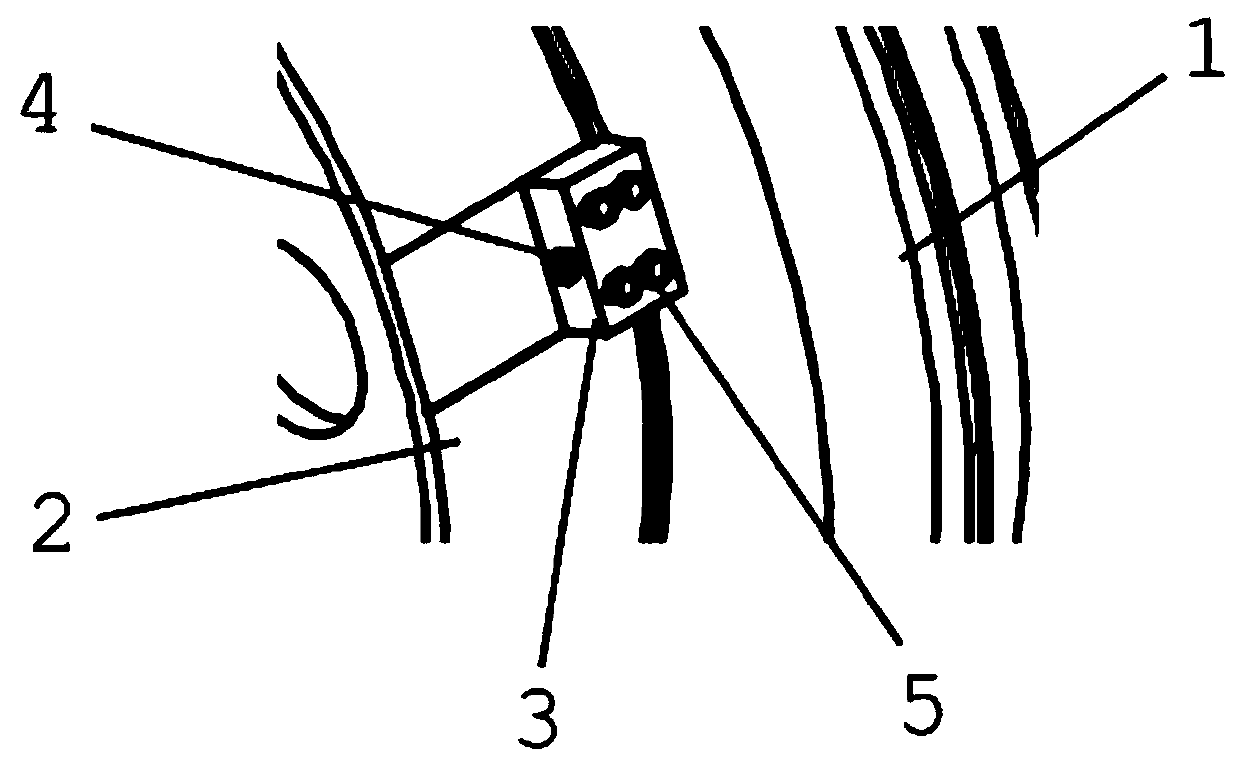

[0041] Such as figure 1 , figure 2 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a processing and clamping device for a thin-walled frame includes a main coil clamping cylinder 2, sixteen positioning block assemblies 3, and sixteen sets of positioning block mounting bolts 5 corresponding to the positioning block assemblies 3 and Sixteen sets of main coil clamping bolts4. Sixteen positioning block assemblies 3 are divided into two groups, which are evenly arranged on the outer circumferential surface of the main coil clamping cylinder 2 along the circumferential direction. The main coil clamping cylinder 2 is installed inside the main coil frame 1, and the main coil clamping The length of the barrel 2 is greater than that of the main coil frame 1 . The positioning block assembly 3 is composed of a symmetrically arranged outer positioning block 301 and an inner positioning block 302. The outer positioning block 301 and the inner positioning block 302 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com