Air bag clamping device used for lossless clamping of low-rigidity framework type part

A low-stiffness, gripper technology, applied in chucks, metal processing, manipulators, etc., can solve problems such as inability to grip small parts, non-destructive gripping of low-rigidity skeleton parts, and parts deformation, etc., to improve assembly Precision efficiency, convenient operation, and the effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

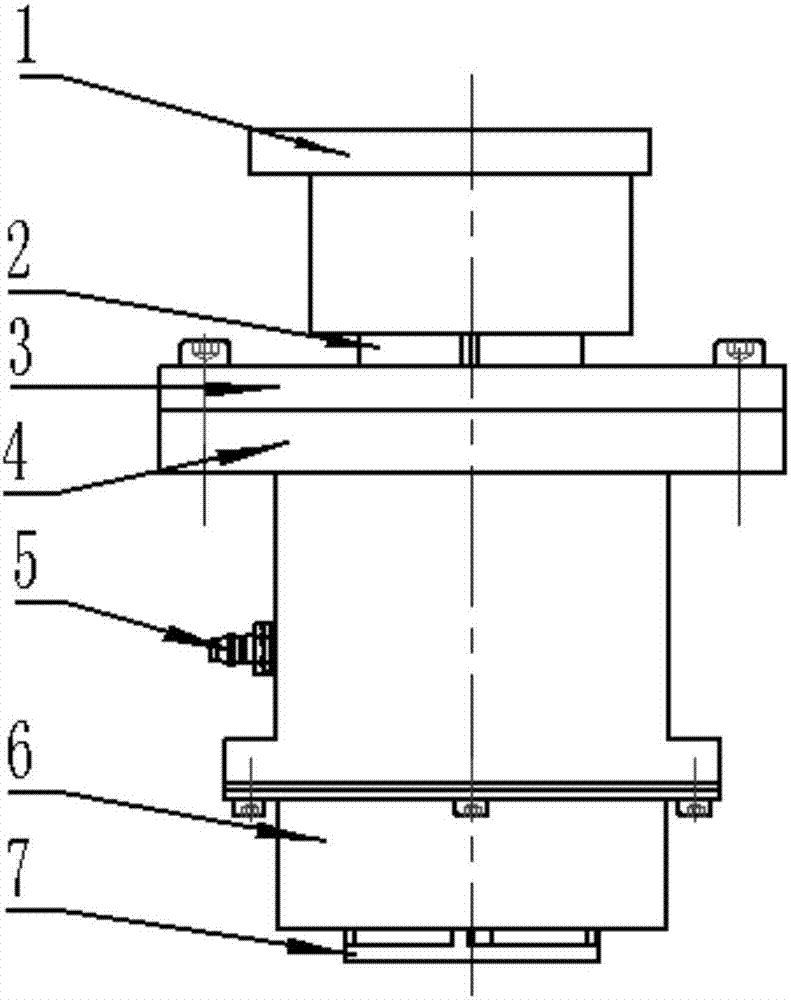

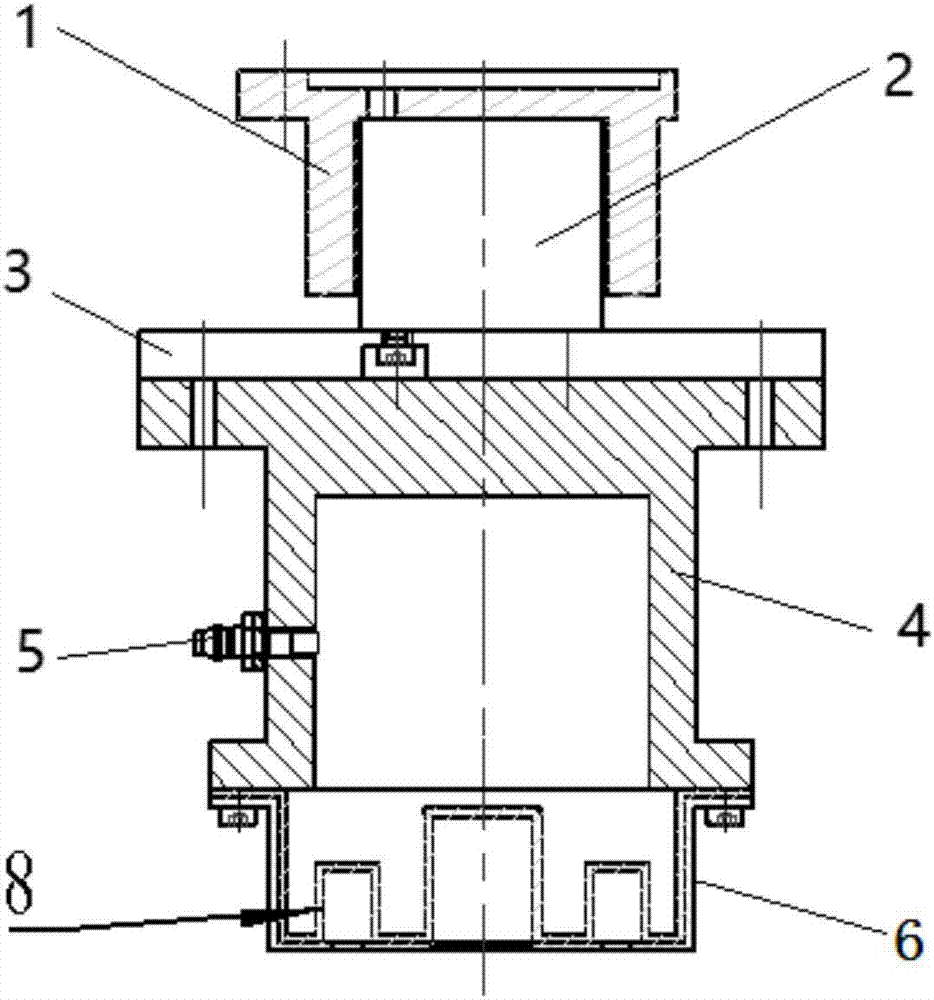

[0033] The invention provides an air bag holder for non-destructive clamping of low-rigidity skeleton parts, see the attached figure 1 and 2 , including: sensor protection fixture 1, six-dimensional force sensor 2, adapter plate 3, air cavity seat 4, cage 6, air bag 8, force monitoring component and air circuit component;

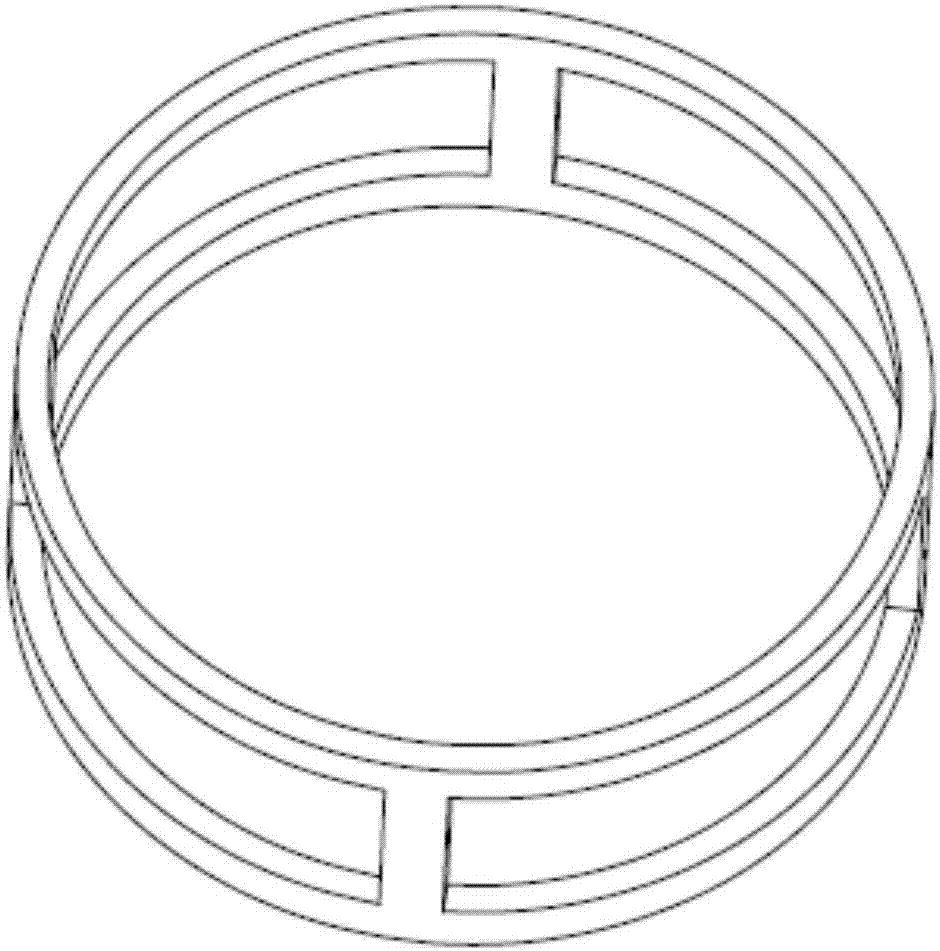

[0034] The parts to be clamped are skeleton parts 7 with low rigidity, and the skeleton parts 7 are integrally formed, see attached image 3 , consisting of two coaxial rings and four support columns connecting the two rings;

[0035] The inside of the air cavity seat 4 is processed with a cylindrical cavity, forming a structure with one end open and one end closed, which plays the role of air path conduction. The lower end surface of the air cavity seat 4 is provided with threaded holes for fixing the air bag 8 And the cage 6, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com