A Method for Using Alloy Casting to Satisfy the Positioning of Complicated Shaped Workpieces

A technology for complex-shaped workpieces and alloys, which is applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve problems such as unfavorable clamping, small blade body, and lack of clamping means for products, and achieve strong application space and solve assembly problems. The effect of clip positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following non-limiting examples illustrate the invention.

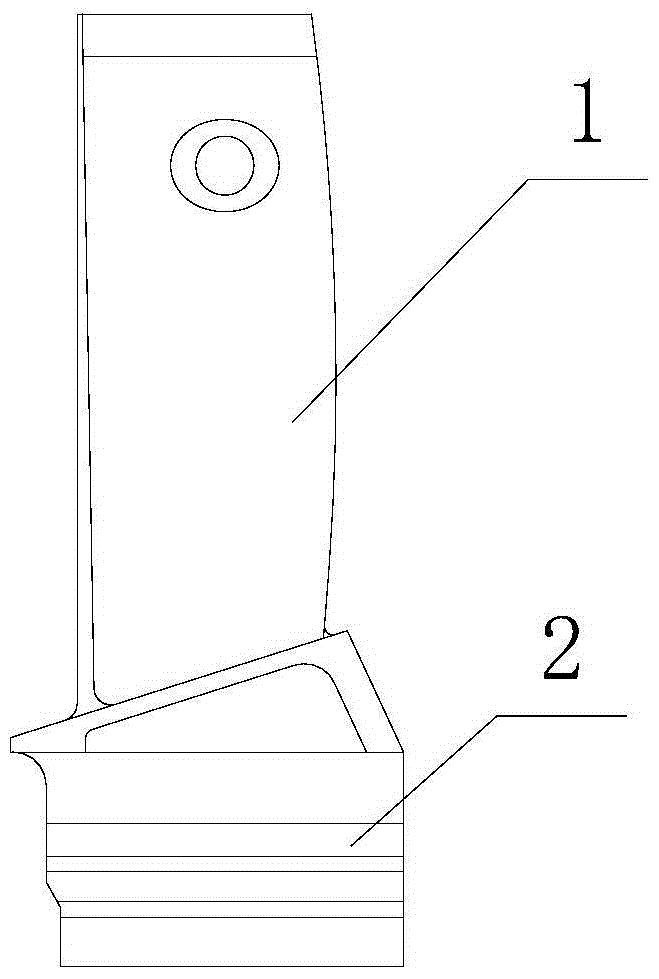

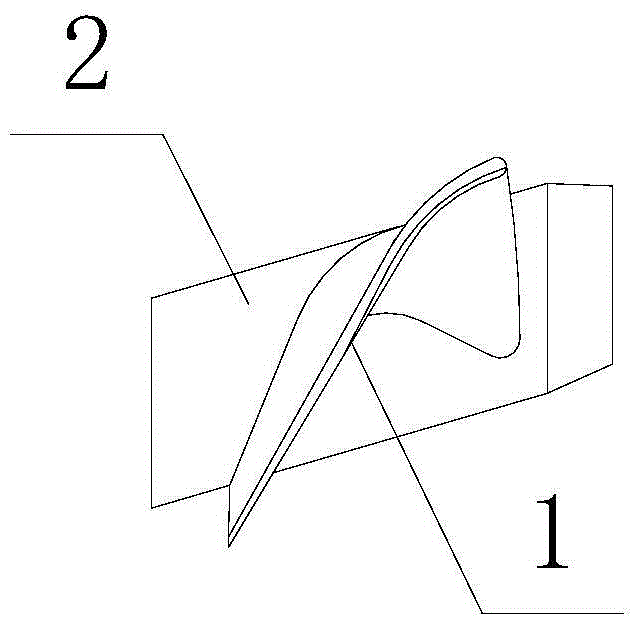

[0034] refer to Figures 1 to 2 As shown, a method of using alloy casting to meet the positioning of workpieces with complex shapes, including turbine blades, the turbine blades are composed of blade body 1 and tenon 2, and includes the following steps in turn:

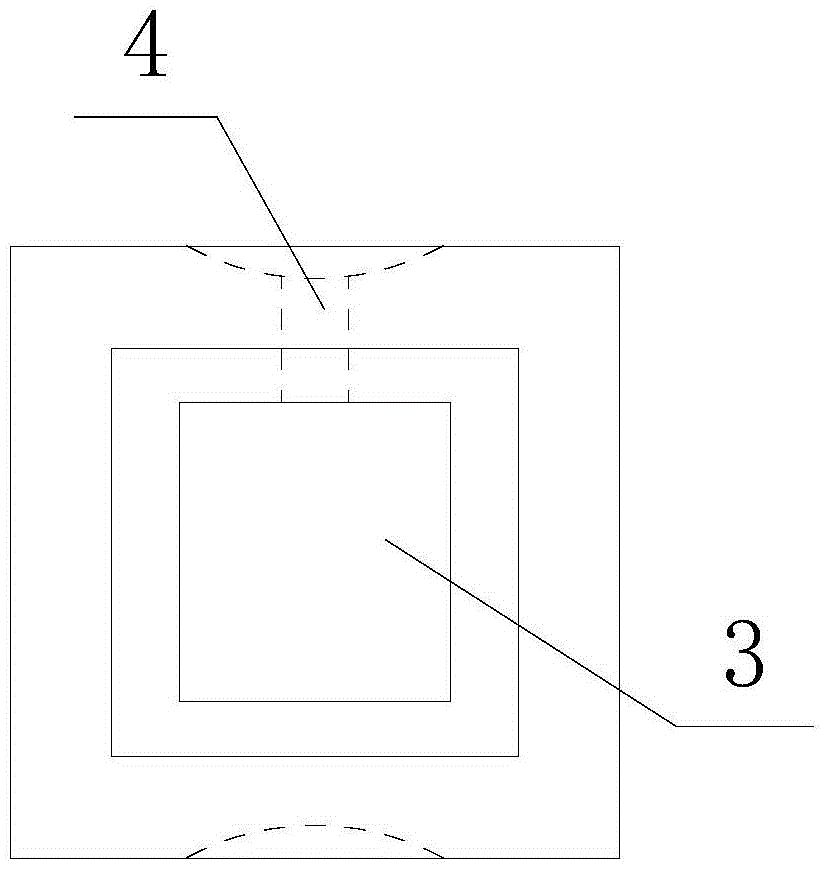

[0035] A. Reference Figures 3 to 9 As shown, the square box and cast tire are prepared: the square box is used to integrate with the turbine blade after pouring to facilitate subsequent processing; the cast tire is used to pour alloys into the other box and the turbine blade.

[0036] The square box is a rectangular frame body, and the hollow part of the rectangular frame body is a square hole 3 for accommodating the airfoil of the turbine blade. The pouring hole 4; the frame body at one end of the square hole on the square box protrudes to form a boss 5, and the frame body at the other end is recessed to form a groove 6.

[0037] The cast tire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com