Device and method for measuring parallelisms and flatness of circular low-stiffness workpiece

A technology of parallelism and flatness, which is applied in the field of measurement, can solve problems such as inconvenient clamping, large computer resources, and influence on the measurement results of low-rigidity workpieces, and achieve the effect of increasing versatility and smooth motion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings, but the specific embodiment of the present invention is only illustrative rather than restrictive. Processes and ideas, or directly or indirectly used in other related fields, are equally included in the scope of patent protection of the present invention.

[0037] The left and right directions in the present invention are only for convenience of description, and do not constitute a limitation to the present invention.

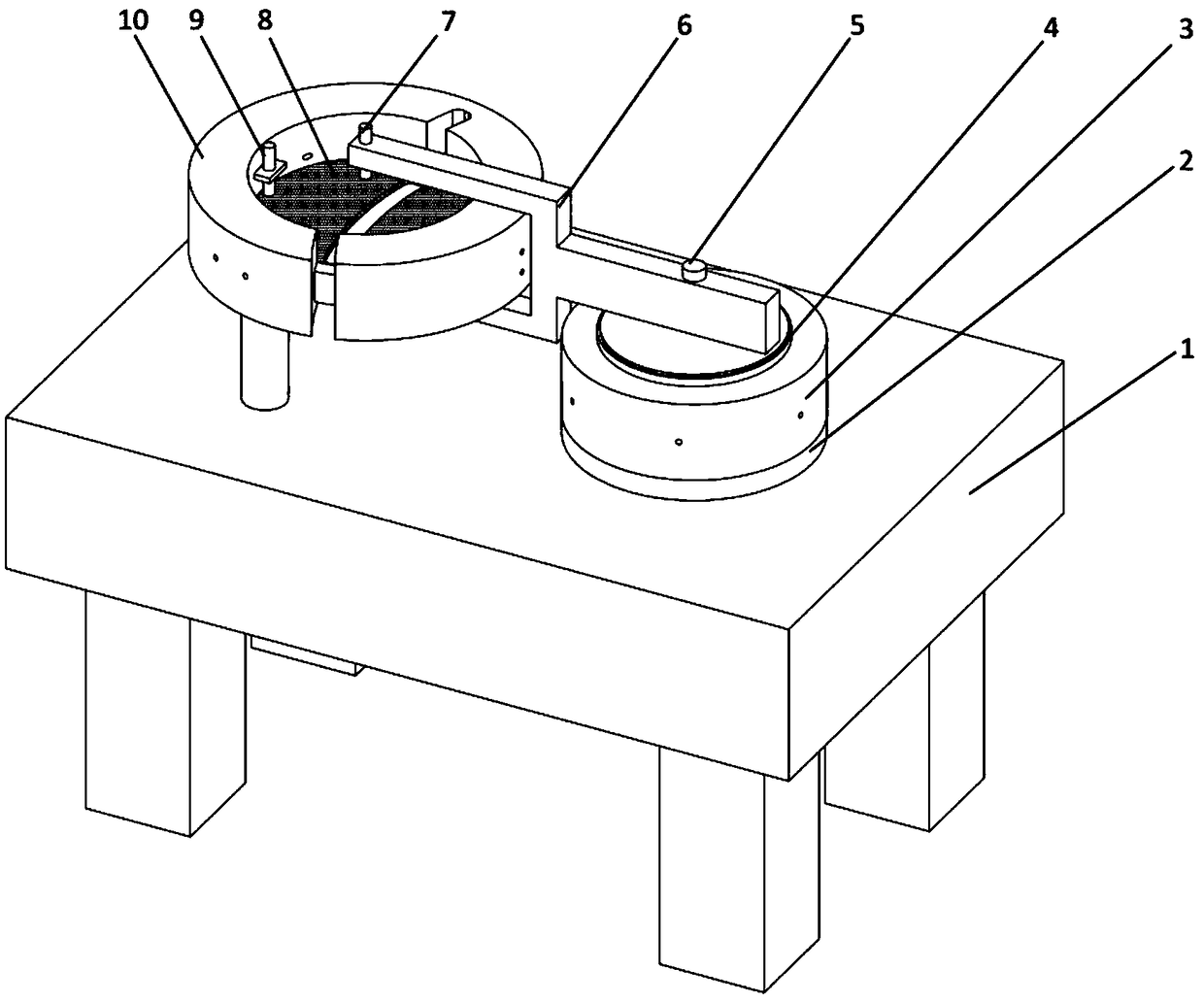

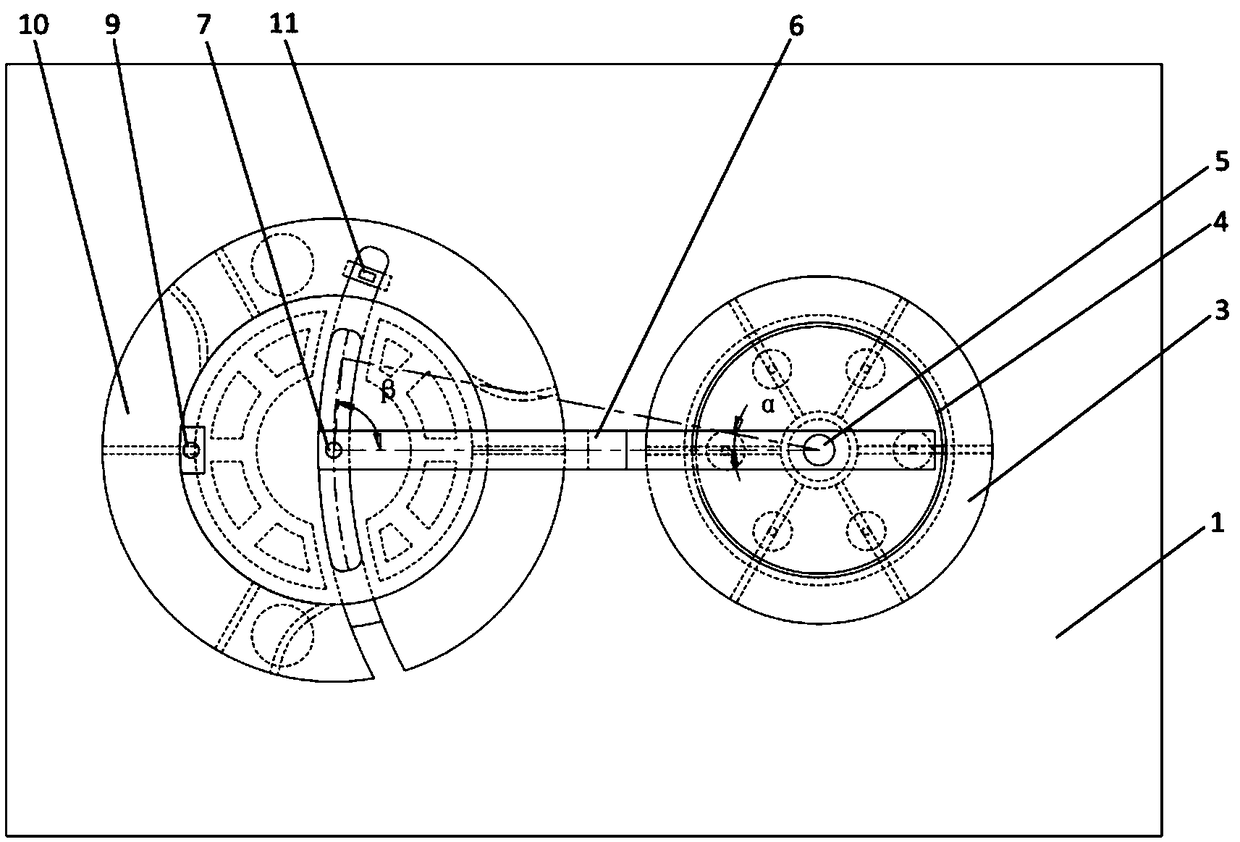

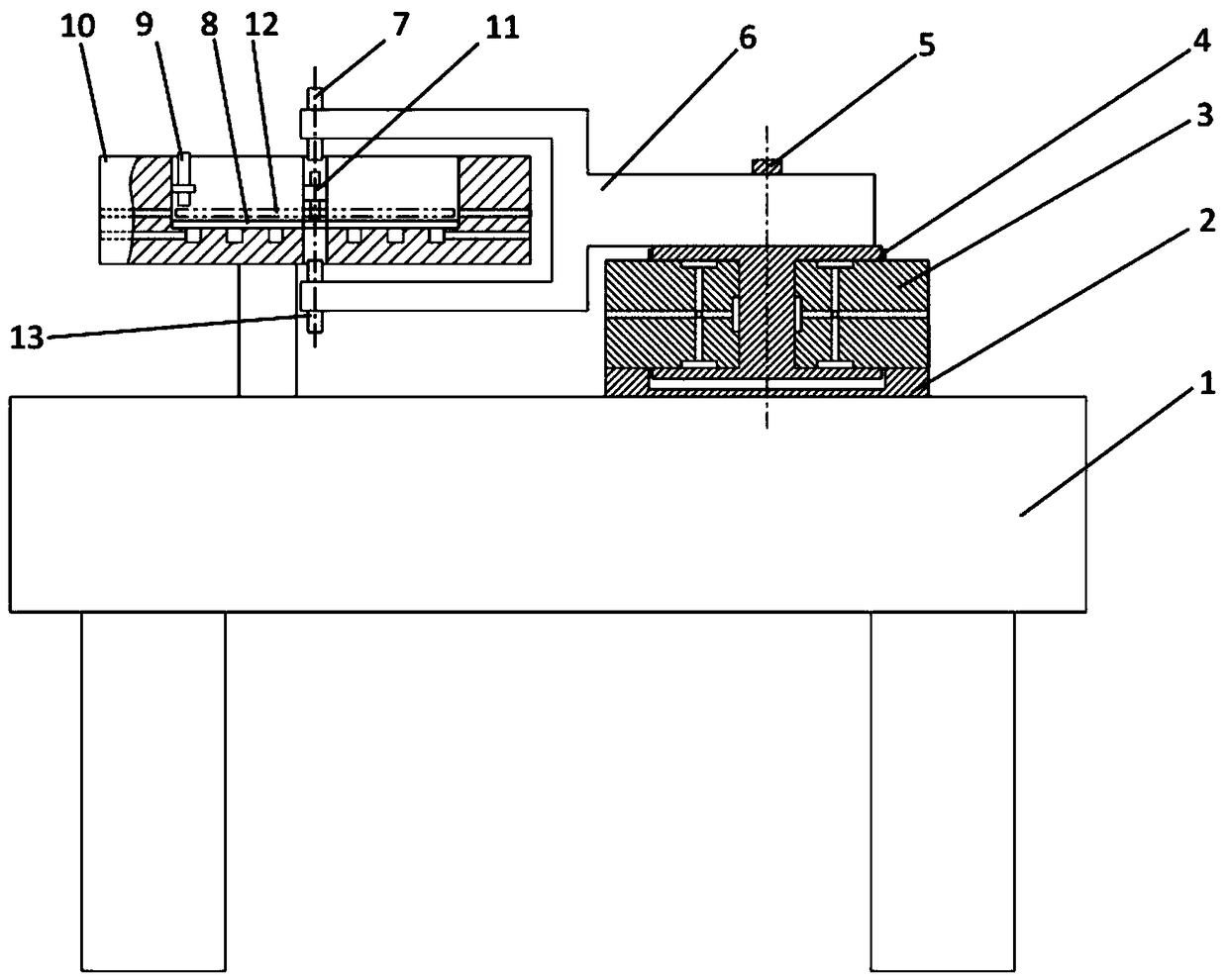

[0038] Such as Figure 1-10As shown, a measuring device for parallelism and flatness of a circular low-rigidity workpiece includes a vibration isolation platform 1, an aerostatic bearing unit, a swing arm unit, a gas channel seat unit, and a data processing unit. The aerostatic bearing The unit and the gas channel seat unit are fixed side by side on the vibration isolation platform 1, and the swing arm u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com