Reciprocating saw

A technology of reciprocating saw and saw blade, applied in the field of reciprocating saw, can solve the problems of danger, unstable cutting, inconvenient movement, etc., and achieve the effect of avoiding too loose or too tight clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

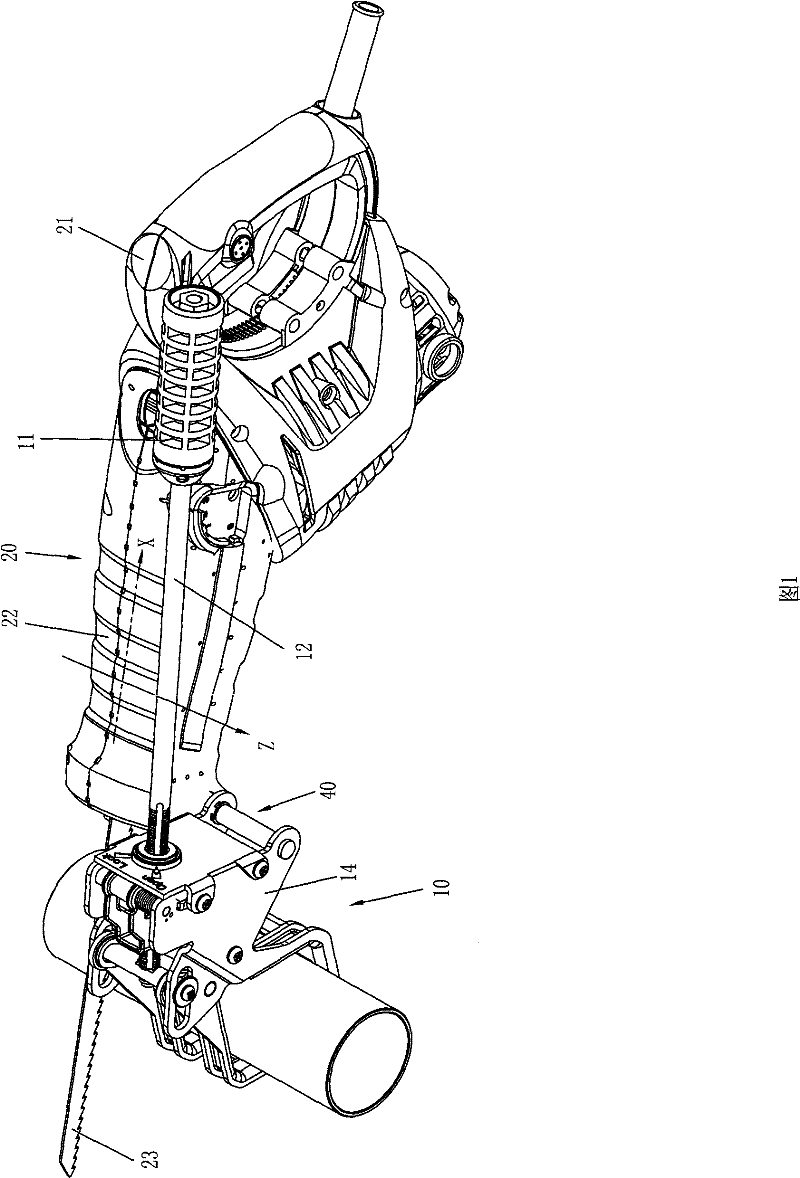

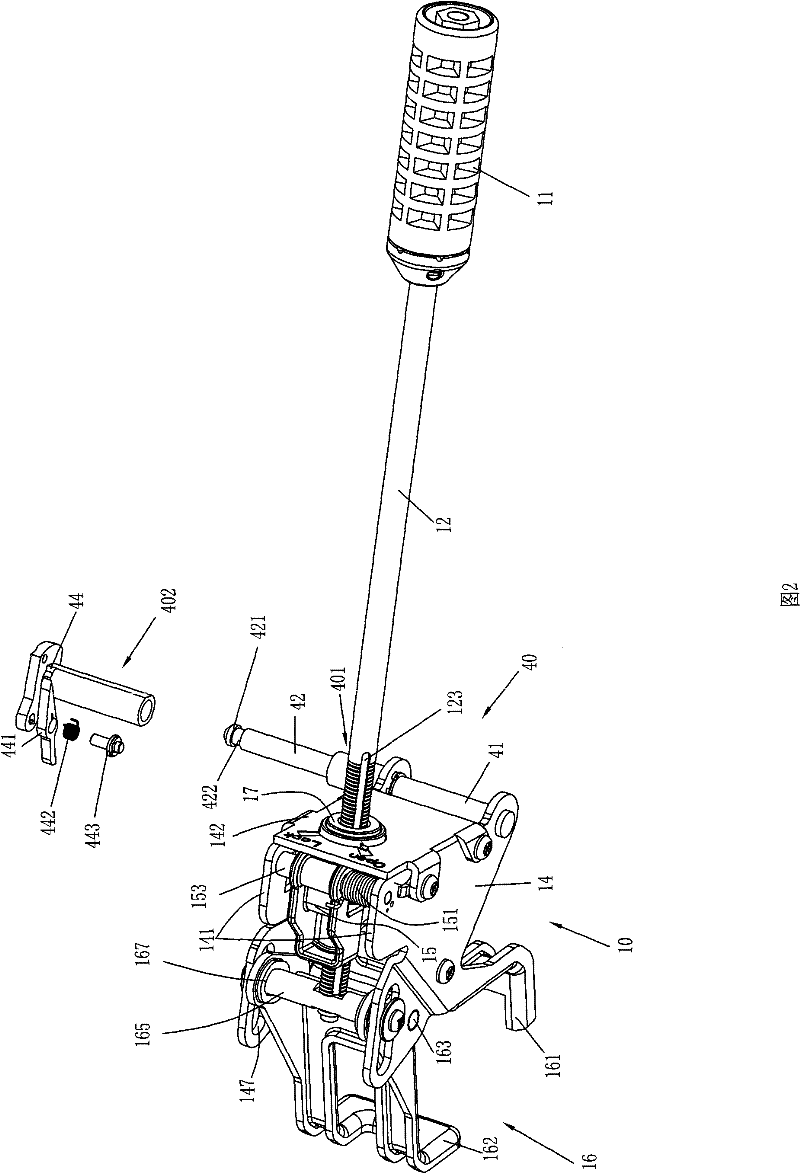

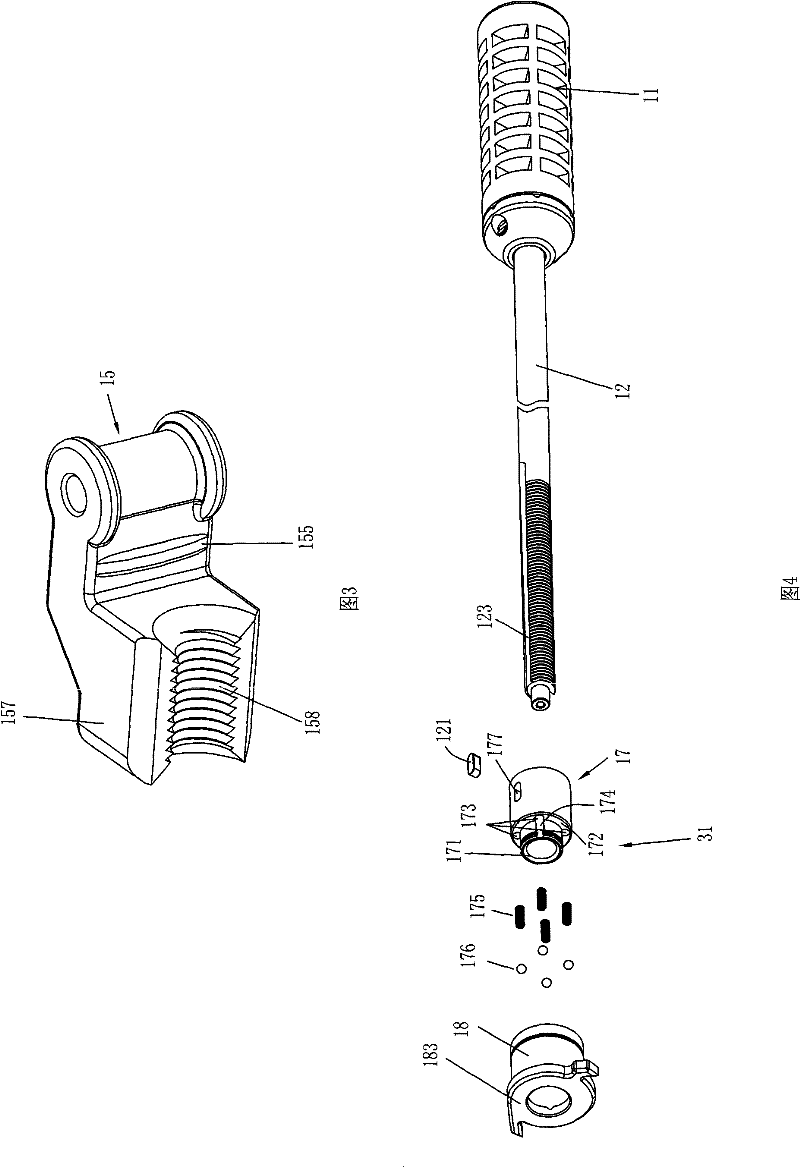

[0048] The invention discloses a reciprocating saw, especially a reciprocating saw with a clamp.

[0049] Figure 1 to Figure 1 0 discloses a preferred embodiment of the present invention, such as figure 1 , like a common reciprocating saw, the reciprocating saw 20 in this preferred embodiment has a housing 22, the housing 22 is formed by joining two half-shells whose outer surfaces are symmetrical to each other, and the joint surface of the two half-shells is is the central axis plane of the housing 22 , the axis Z is defined perpendicular to the central axis plane of the housing 22 . The housing 22 is provided with a motor 5 (see FIG. 11 b ), and the motor 5 is connected to a reciprocating shaft (not shown in the figure). The reciprocating shaft has a free end far away from the motor 5 and a saw blade 23 is connected to it. The motor 5 is suitable for driving the reciprocating shaft to reciprocate and drive the saw blade 23 on it to perform reciprocating cutting action. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com