Strong pulse current orientated solidification grain ultra-fining method and device

A technology of strong pulse current and directional solidification, which is applied in the field of directional solidification and electromorphic pulse processing. It can solve the problems of complex devices, high production costs, and difficulty in obtaining radial dimensions, and achieve simple equipment, high efficiency, and simple equipment. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

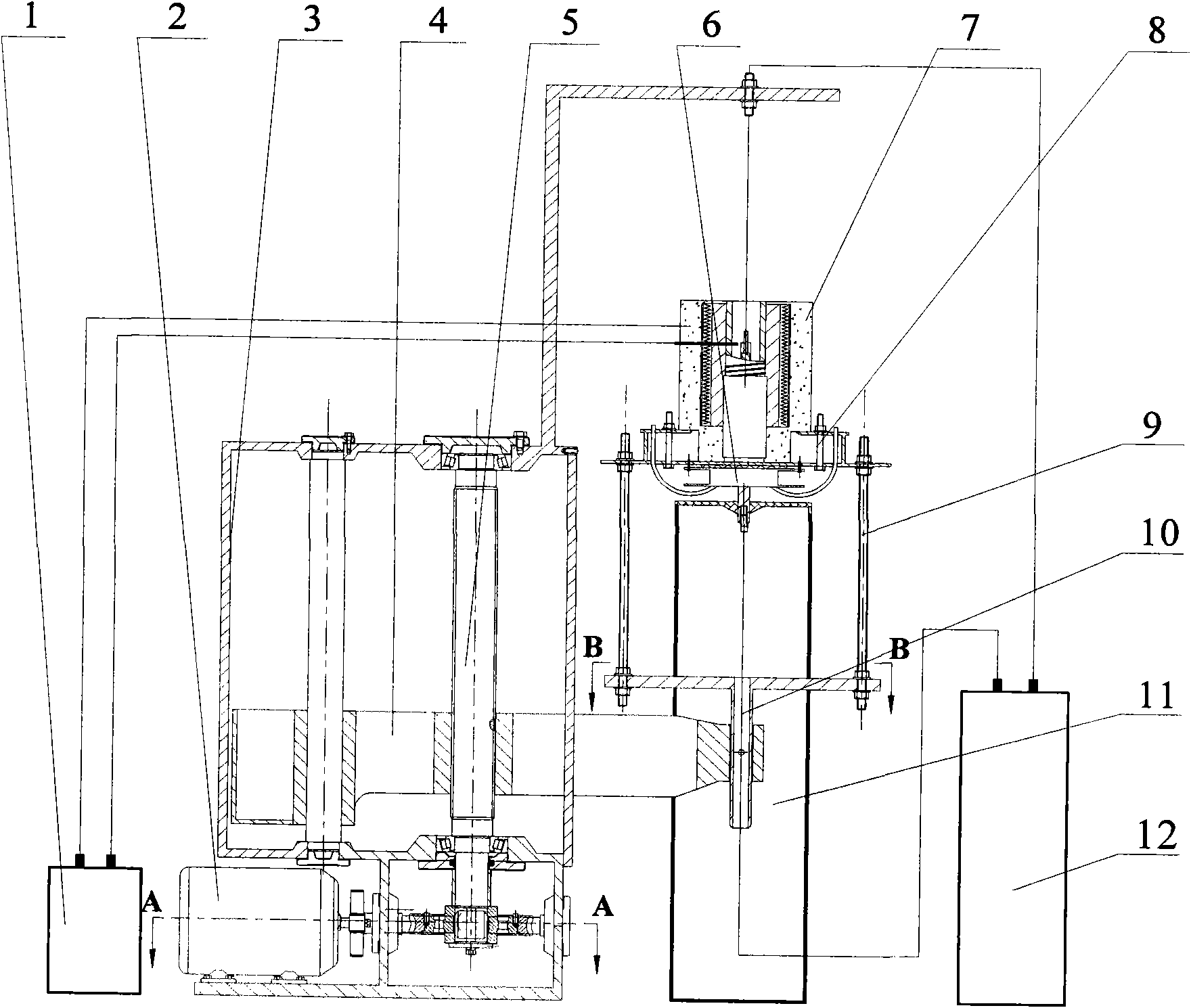

[0032] The method and device of the present invention for directional solidification of strong pulse current crystal grains combine the pulse current processing technology with the directional solidification technology as an implementation technical method, and apply high-density pulse current treatment to the metal melt, so that the metal material can be heated in one heating process. Simultaneously complete the radial size of grains and obtain oriented columnar crystals.

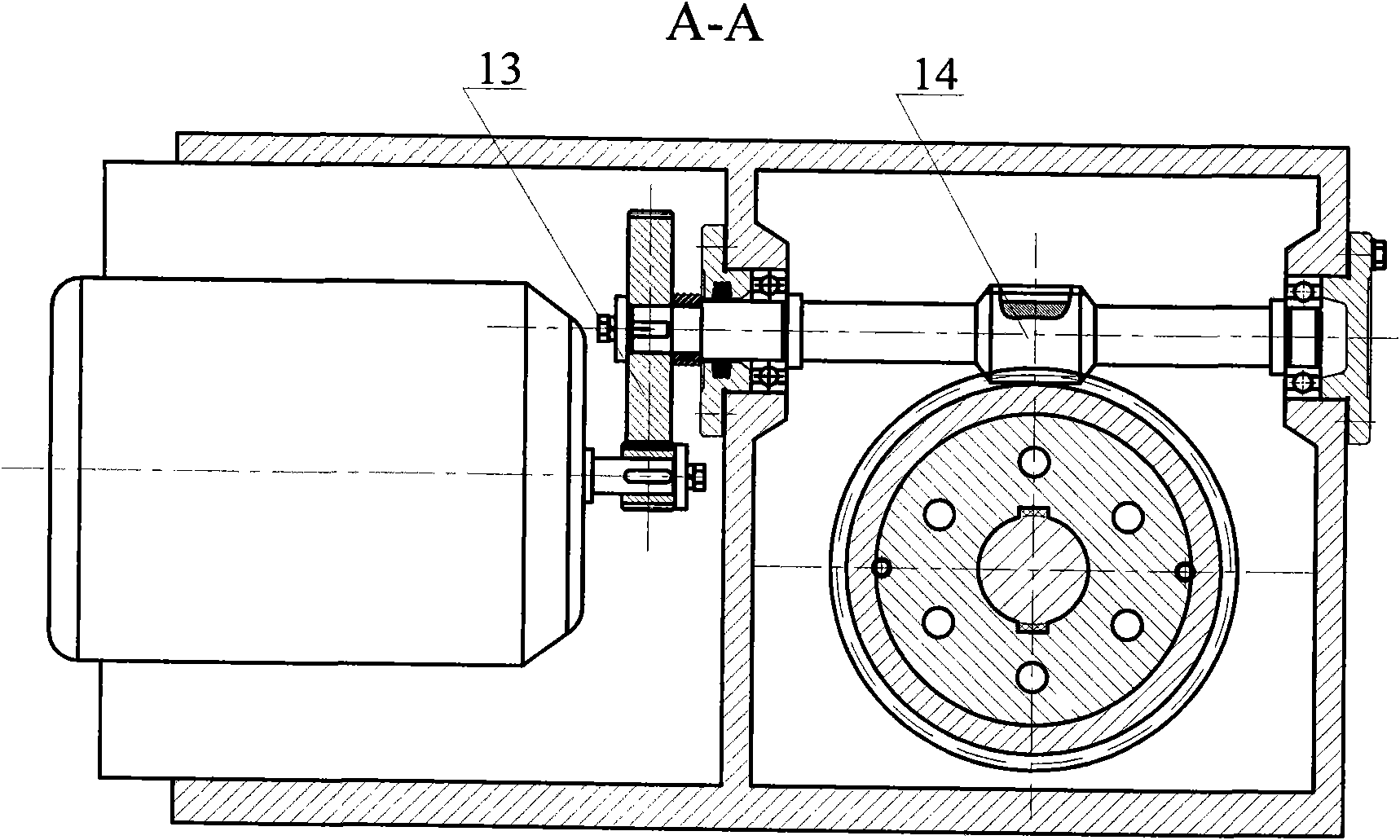

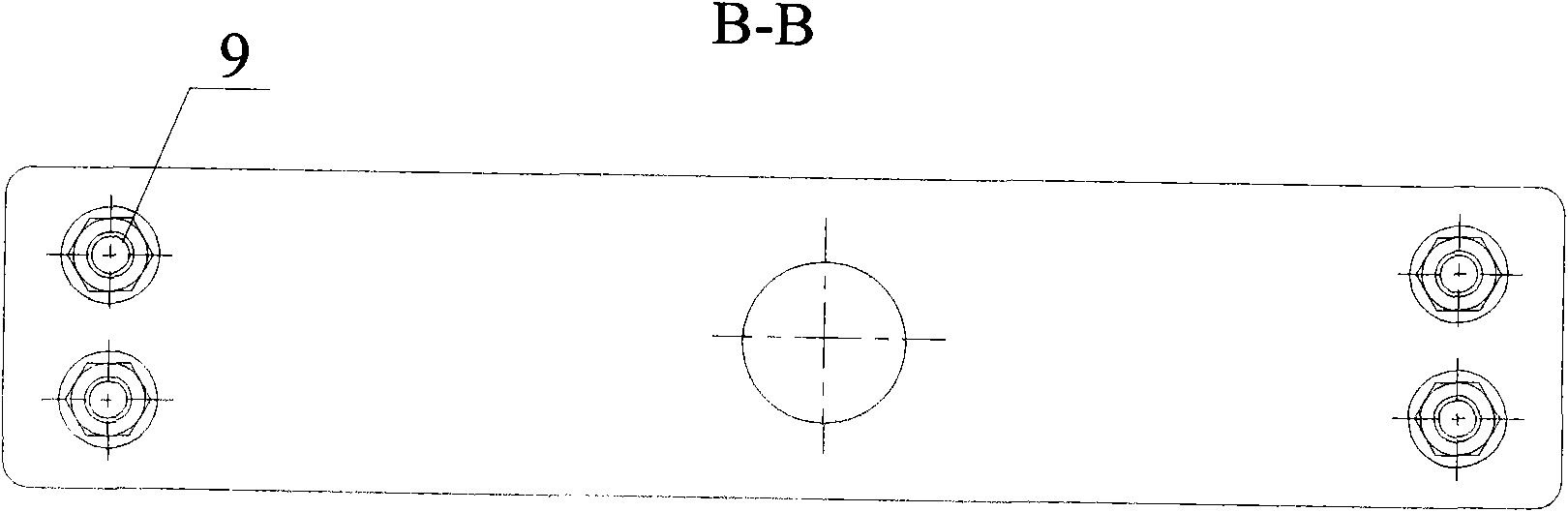

[0033] Such as figure 1As shown, the method and device for ultra-refining crystal grains by strong pulse current directional solidification of the present invention are composed of a pulse current generator and a directional solidification device. The pulse current generating device provides current pulses to the molten metal to continuously impact the growing grain structure, resulting in fine grains; the directional solidification device provides the temperature gradient during the metal solidification p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com