Pulse trigger

A technology of pulse triggering and ignition tube, which is applied to machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of less query results, less verification of large engines, and lack of verification technology, and achieves clear principles and consistency. Good, good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Engine pulser trigger pressure curve as Figure 7 shown.

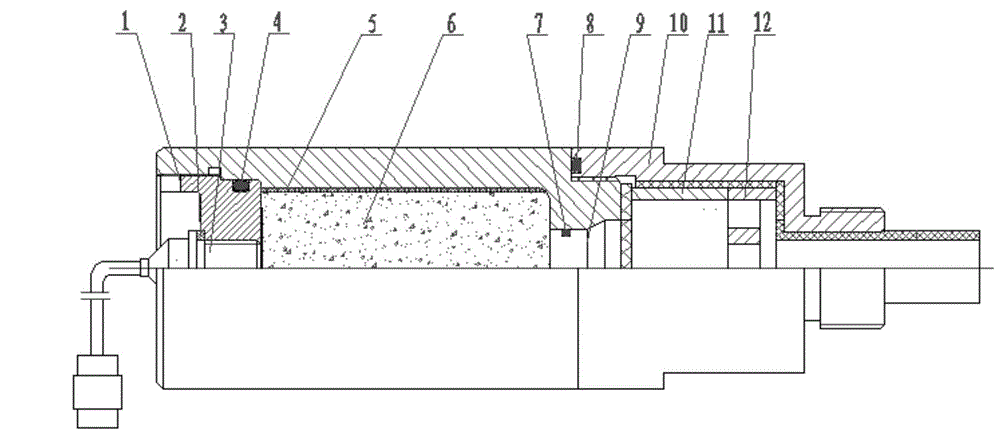

[0041] Pulse trigger outline size: Φ60mm×205.5mm; gas inlet diameter: Φ14mm; trigger dose: 45g; trigger times: 2 times; trigger time engine work: 15s, 17s; trigger pressure: 0.22MPa, 0.28MPa; trigger action time : 2ms.

Embodiment 2

[0043] Engine pulser trigger pressure curve as Figure 8 shown.

[0044] Pulse trigger outline size: Φ60mm×205.5mm; gas inlet diameter: Φ14mm; trigger dose: 65g; trigger times: 1 time; trigger time engine operation: 4.5s; trigger pressure: 2.59MPa; trigger action time: 2.3ms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dc resistance | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com