Method for sealing lancing type crystallizer copper pipe using electromagnetic pressure

A mold copper tube and electromagnetic technology, which is applied in the field of slit type mold for electromagnetic soft contact continuous casting, can solve the problems such as the inability of the sealing medium to connect with the copper tube, and achieves low manufacturing cost, convenient operation and simple process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

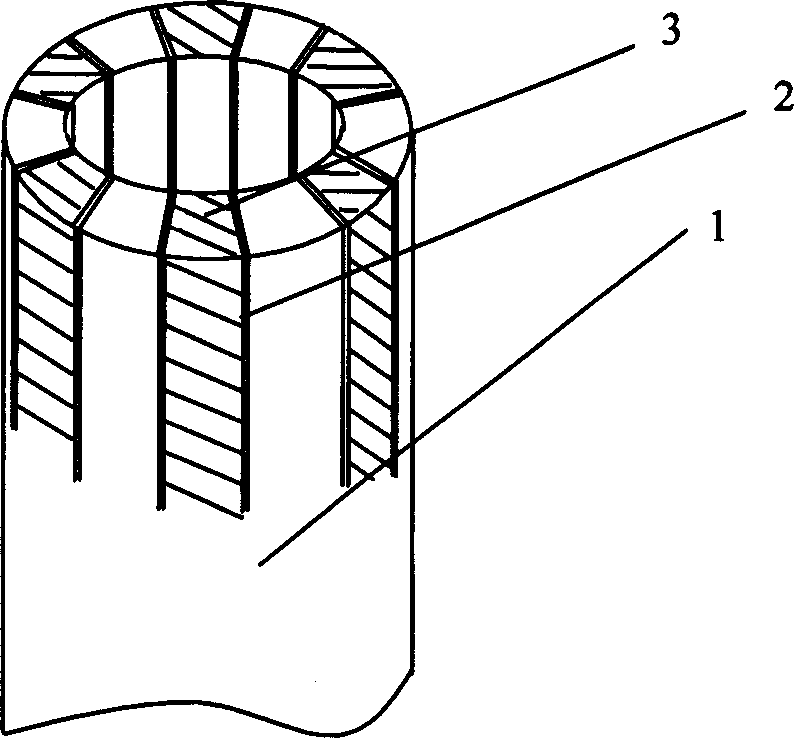

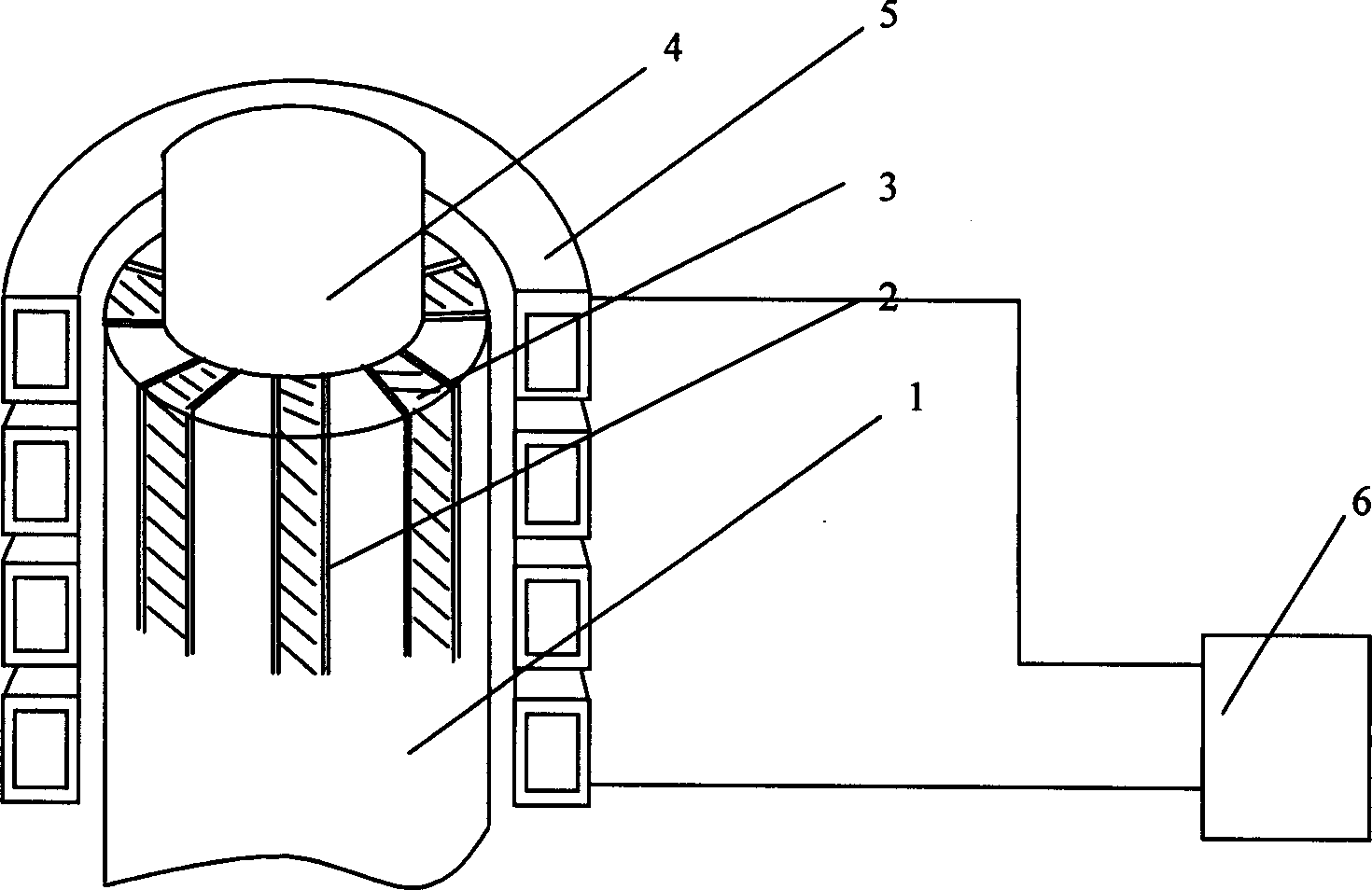

[0018] Embodiment 1, at first select Ag-Cu crystallizer copper tube 1 for use, adopt the middle slit form to implement slit 2 to Ag-Cu crystallizer copper tube 1, the width of slit 2 is 0.6mm, and the end of slit 2 is processed as Rounded corners (diameter equal to slit width). ZrO 2 The ceramic sheet 3 is an insulating and non-magnetic medium, with a temperature resistance higher than 1000° C., a compressive strength greater than 800 MPa, and a thermal expansion coefficient similar to that of the crystallizer copper tube 1 . ZrO 2 Ceramic 3 slices are processed into thin slices with a thickness of 0.54-0.58mm, both ends of the slices are processed into circles, and the surface roughness of the slices is between Ra12.5-50um after roughening. In order to prevent the ceramic sheet 3 from loosening or falling off after being inserted into the slit 2 or leaving air in the slit 2, apply Vaseline to the entire crystallizer slit 2, and then insert the ceramic sheet 3 into the coppe...

Embodiment 2

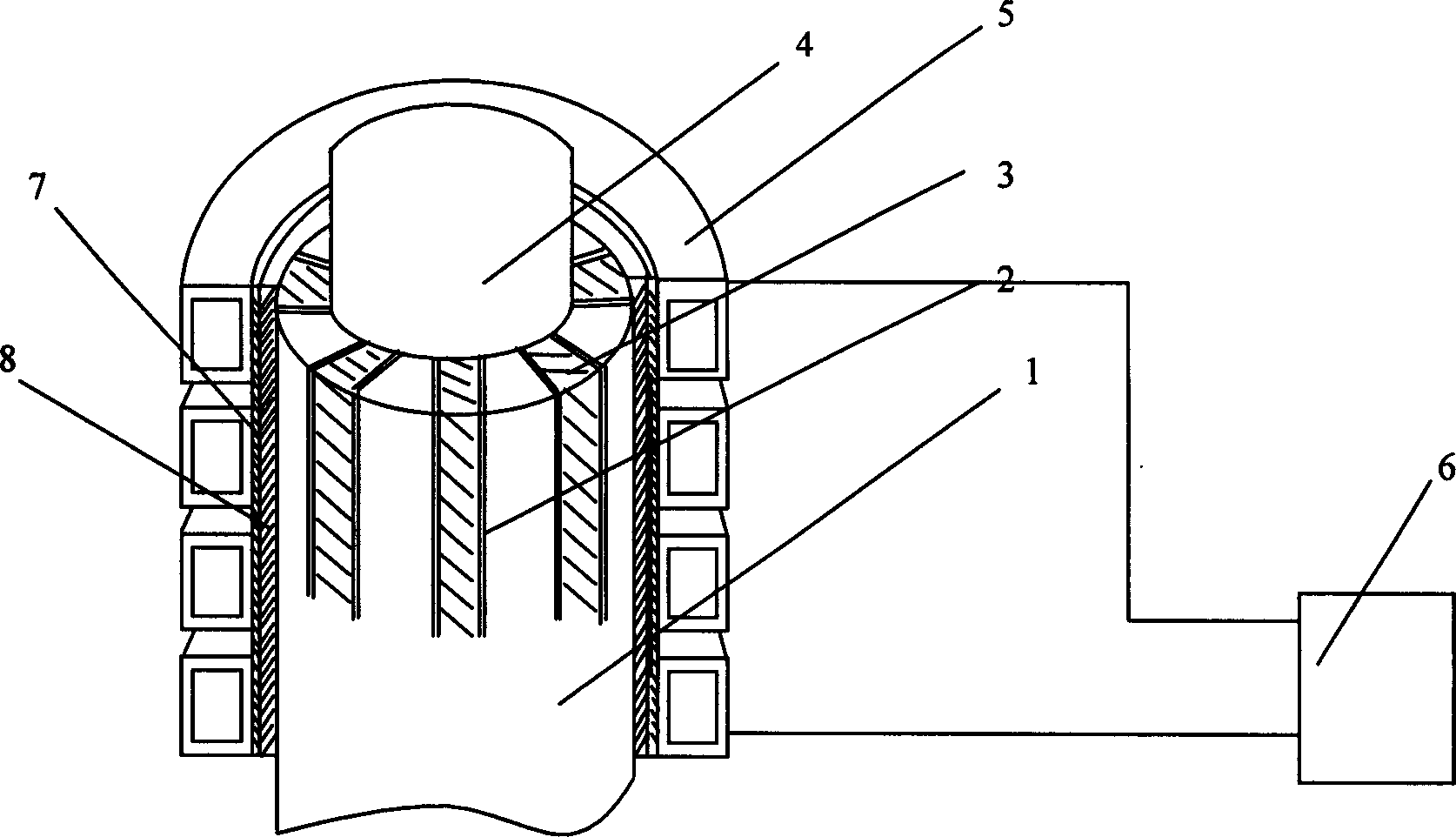

[0021] Embodiment 2, using red copper magnetically driven cylindrical ring 7 and polyurethane cylindrical ring 8 to transmit electromagnetic pressure to crystallizer copper tube 1 to make it undergo shrinkage plastic deformation, red copper magnetically driven cylindrical ring 7 is close to electromagnetic working coil 5, polyurethane Cylindrical ring 8 is close to crystallizer copper pipe 1 and has the same height as electromagnetic working coil 5 . Other structures and electromagnetic parameters are exactly the same as those in Embodiment 1.

[0022] The invention is simple in operation and reliable in sealing, and is suitable for square billets, round billets, whole-body slits, upper-end whole-body slits or middle slits, and the slits of electromagnetic soft contact continuous casting crystallizer copper tubes 1 with a slit width of 0.2 mm to 10 mm 2 sealed. At the same time, all the plastic deformation and sealing of the present invention work under the condition close to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com