Organic fertilizer fermentation method

A fermentation method and organic fertilizer technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve problems such as high cost, increased agricultural production burden, complicated production process, etc., and achieve the goal of reducing the influence of unfavorable factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

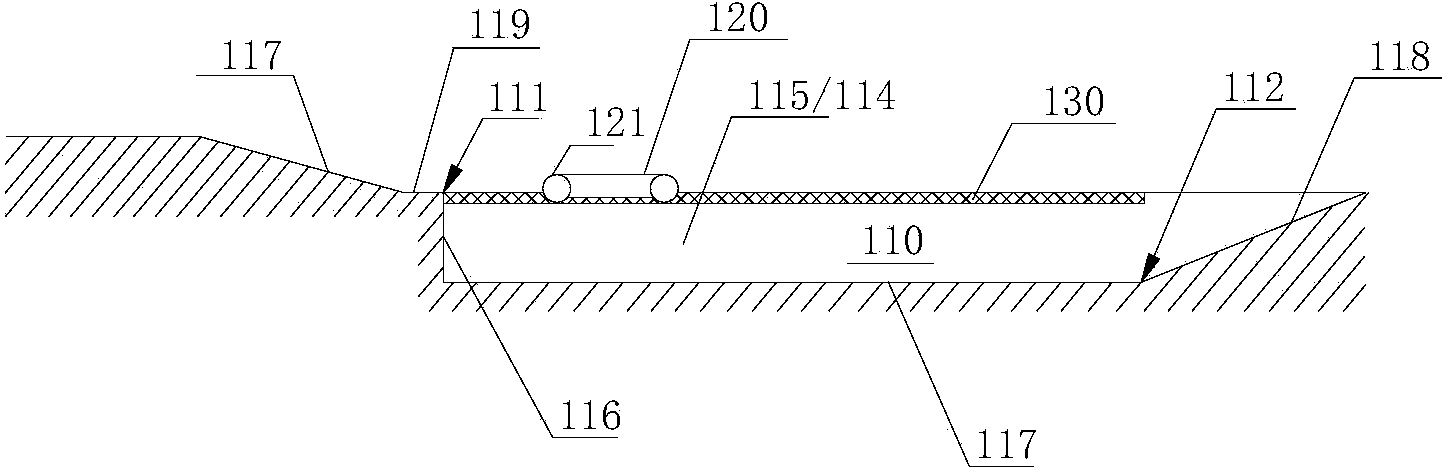

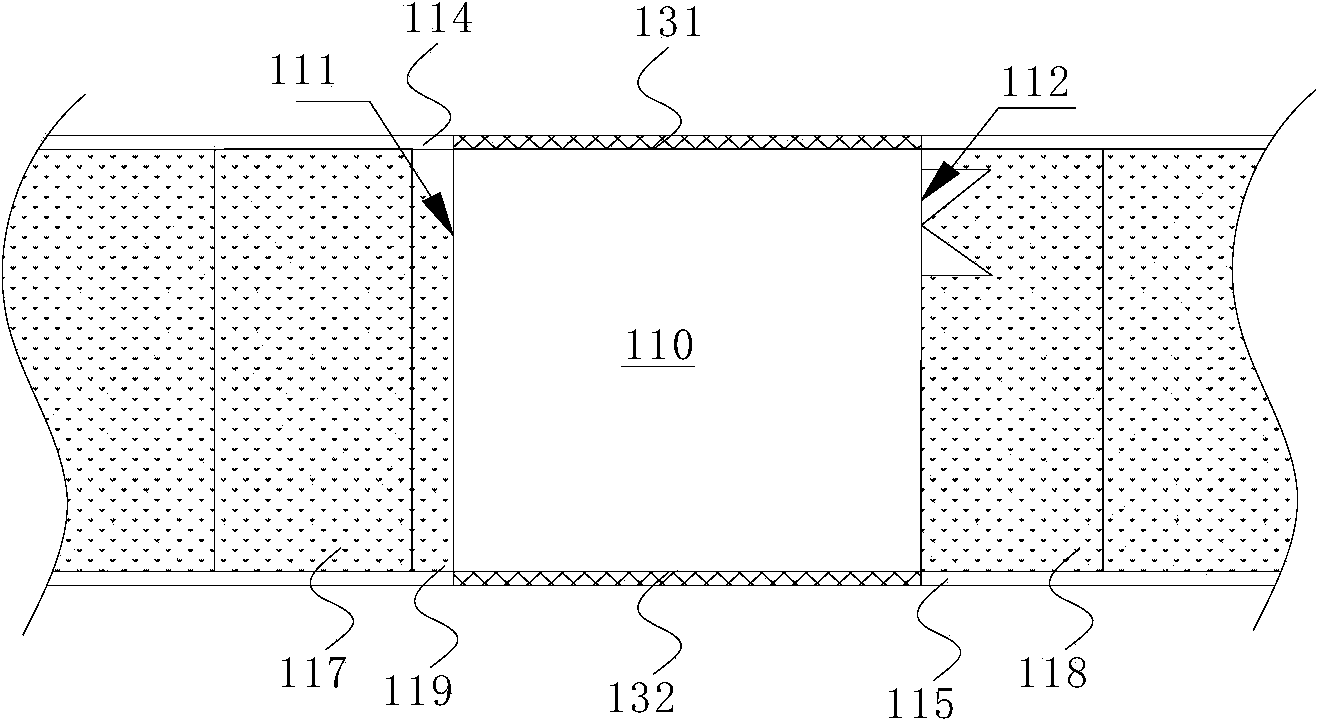

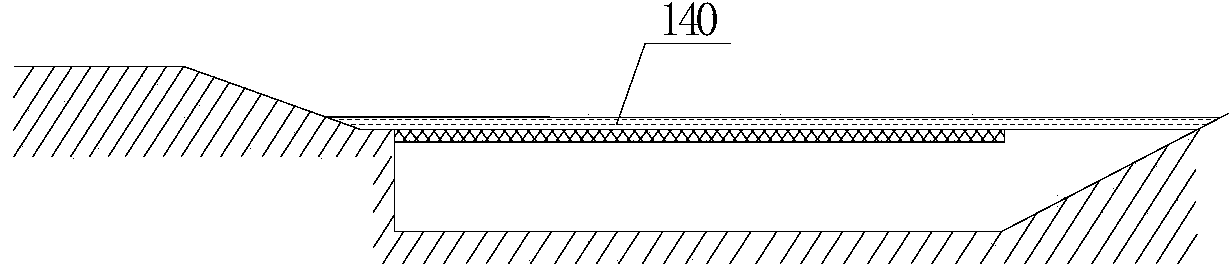

[0024] refer to figure 1 , figure 2 and image 3 As shown, the organic fertilizer fermentation equipment 100 according to this embodiment includes a fermentation tank 110 and a turning machine 120 .

[0025] The fermentation tank 100 of this embodiment is preferably rectangular, and has a front wall 116, a bottom wall 117 and two opposite side walls 114 and 115, which together form an accommodating space for placing and carrying out fermentation raw materials. The first fermentation. The preferred size of the fermentation tank 110 in this embodiment is 30m in length, 20m in width, and 1.5m in height. In other embodiments, fermentation tanks of other shapes or sizes can be formed according to actual needs.

[0026] The upper edge of the front wall 116 of the fermentation tank 110 is provided with a feeding port 111, and the bottom wall 117 thereof is directly connected with the discharging port 112, and the feeding port 111 and the discharging port 112 are arranged opposite...

Embodiment 2

[0049] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that 750kg of solid organic waste fresh chicken manure (water content is 55%), microbial fermentation inoculants (including yeast, bacillus, filamentous fungi, actinomycetes mixture ) 249.9kg and auxiliary material mushroom residue 0.1kg are mixed evenly to obtain fermentation raw materials. The stacking height of the fermentation raw materials in the organic matter fermentation tank is 100 cm, and the first fermentation is carried out. Among them, the fermentation temperature is about 60°C, and the fermentation time is 8 days. During the period, the fermentation raw material is continuously turned by a turning and throwing machine to make it fully contact with the air to obtain a primary fermentation product. The primary fermentation product is then fermented fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com