A double-sealed connection structure between the combustion chamber flame tube and the transition section of a gas turbine

A gas turbine and connecting structure technology, which is applied to gas turbine devices, combustion chambers, continuous combustion chambers, etc., can solve the problems of easy wear of elastic seals, difficult to control, and passage of cold air, and achieves increased flow rate, enhanced controllability, and convection conversion. heat-enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

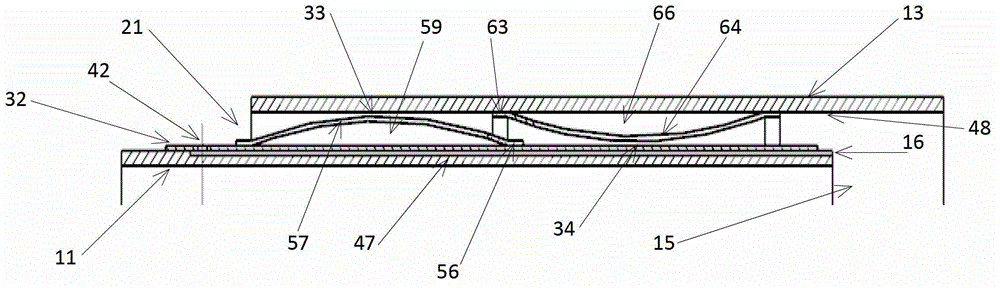

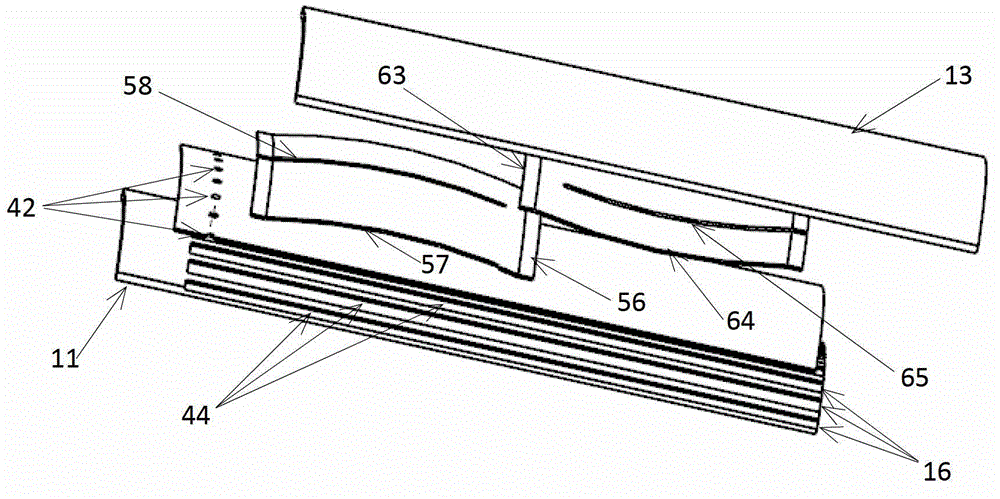

[0018] figure 1 It is a schematic diagram of the structural principle of a double-sealed connection structure between the flame cylinder and the transition section of the gas turbine combustor provided by the present invention. The connecting structure includes a flame tube 11, a transition section 13 and a sealing structure 21; the flame tube 11 is inserted into the transition section 13, and the combustion flow channel 15 is formed by the inner wall surface of the flame tube 11 and the transition section 13, and the sealing structure 21 is arranged in the flame tube 11 and the transition section 13.

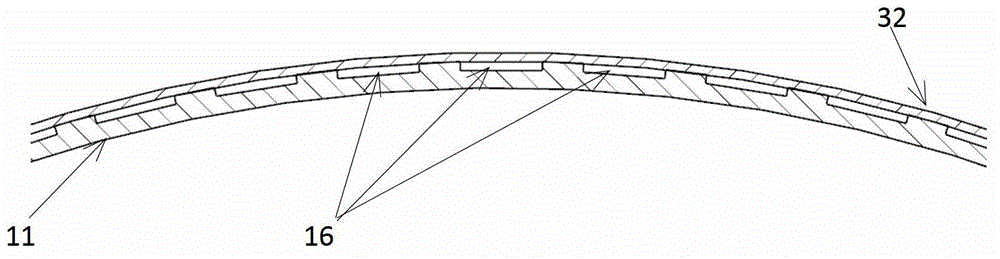

[0019] The sealing structure 21 includes a sealing support 32, a front elastic seal 33 arranged on the flame tube and a rear elastic seal 34 arranged on the transition section; the seal support 32 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com