Sludge treatment device based on electrolysis and pressure filtration technologies and method thereof

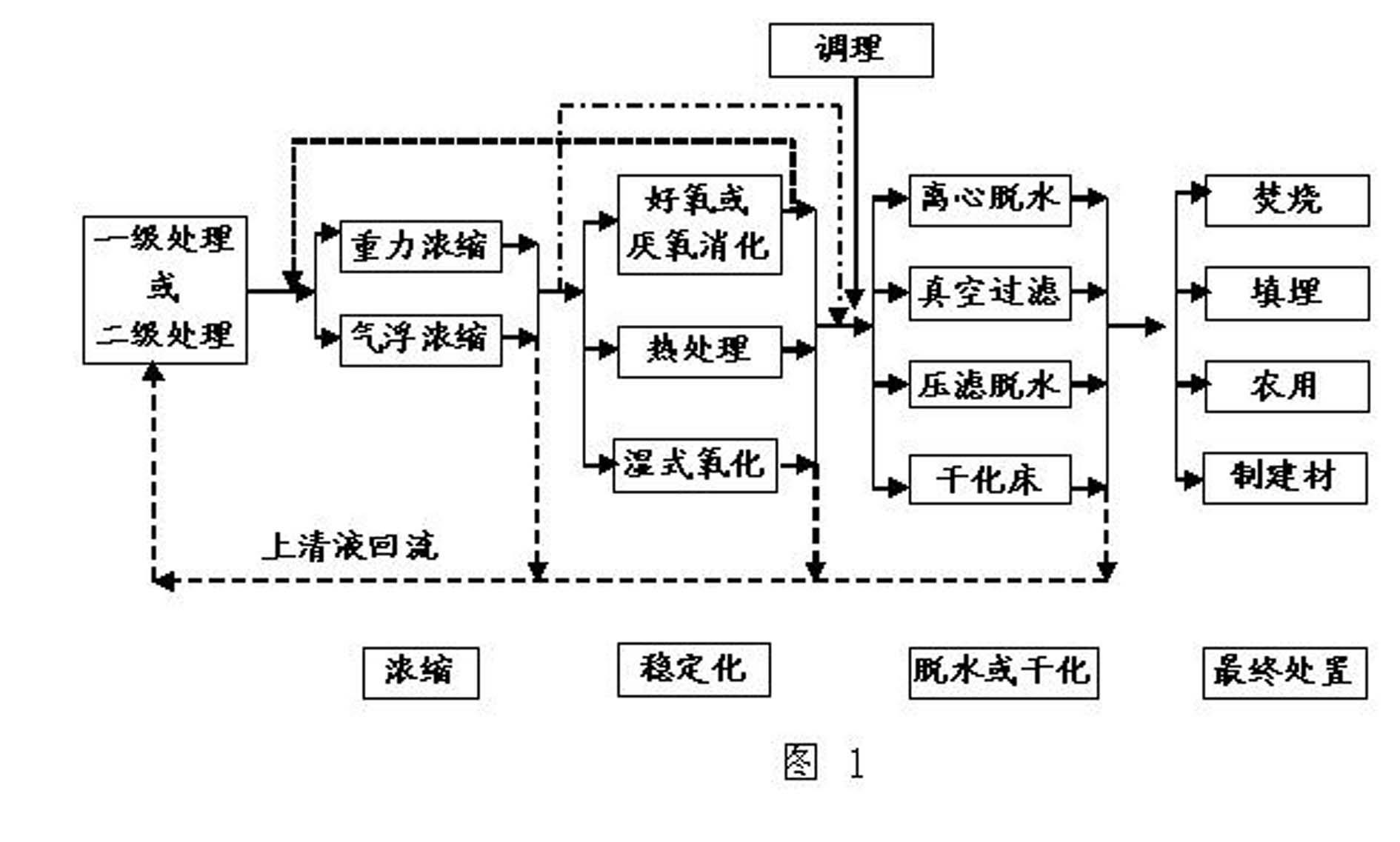

A technology for sludge treatment and technology, which is applied in the field of sludge treatment devices based on electrolysis and filter press technology, can solve the problems of long treatment cycle, high operating cost, and large investment, and achieve enhanced biodegradability and reduced sludge volume , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

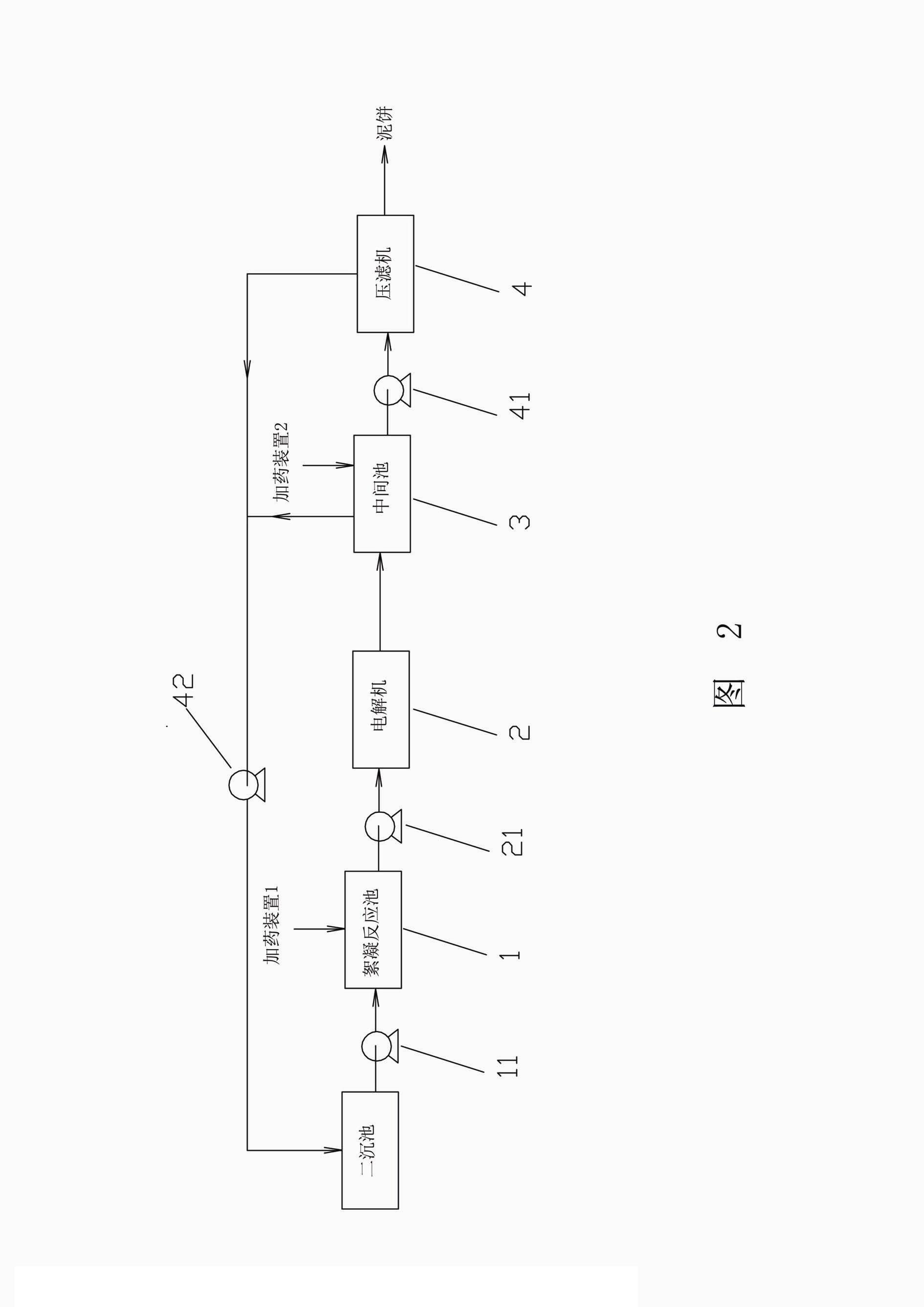

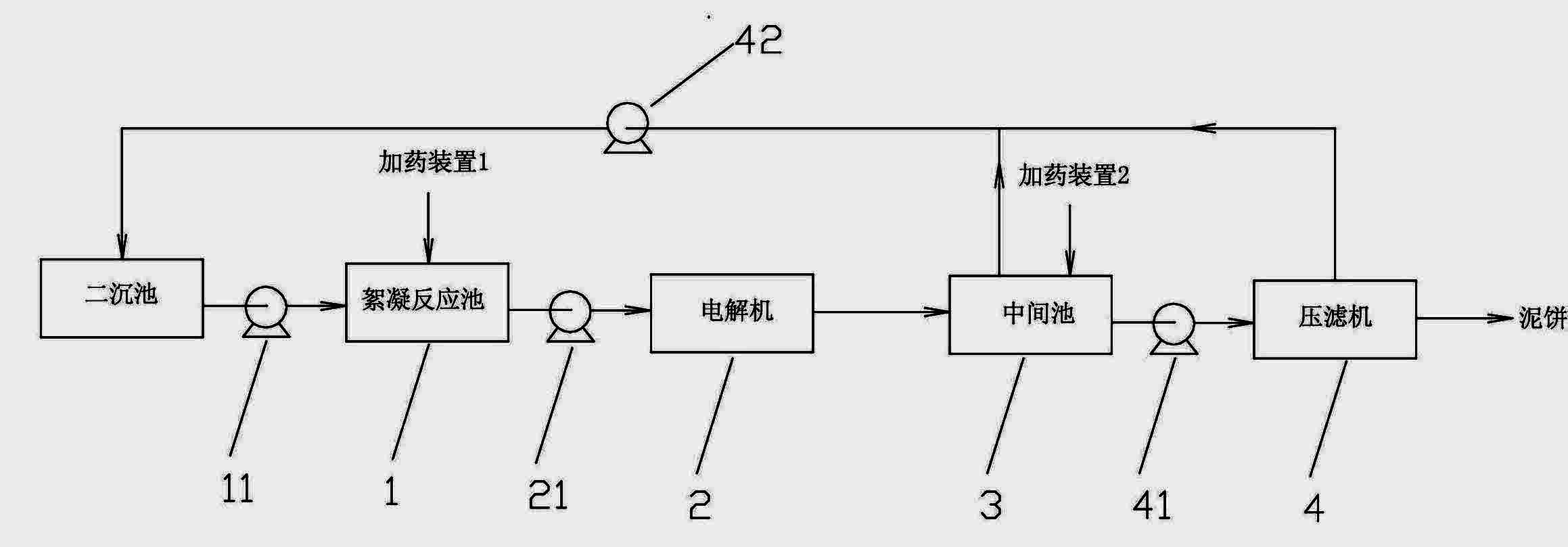

[0033] A 50,000-ton / day sewage treatment plant produces 500 tons of sludge with a moisture content of 99% per day, and its sludge treatment design is as follows:

[0034] (1) Two primary sludge pumps (one for use and one for standby), model: 100WL100-15-7.5 vertical sewage pump, Q=100m3 / h, H=15m;

[0035] (2) Flocculation reaction tank 1: steel concrete tank, specification: 5×5×3m, effective volume 50m 3 , with a designed sludge retention time of 2 hours and a 3 m 3 One ferric chloride dosing device;

[0036] (3) Two secondary sludge pumps (one for use and one for standby), model: 80WL50-25-7.5, vertical sewage pump, Q=50m3 / h, H=25m;

[0037] (4) 7 nano-catalytic electrolysis machines (5 for use and 2 for standby), model: BYDW-I [produced by Boying (Xiamen) Technology Co., Ltd.], the sludge treatment capacity of a single machine is 5 m 3 / h;

[0038] (5) 2 middle pools: steel concrete pool, specification: 10×6×3.5m, effective volume 150m 3 , the design sludge retention ti...

Embodiment 2

[0055] A 10,000-ton / day sewage treatment plant produces 100 tons of sludge with a moisture content of 99% per day. The sludge treatment includes the following steps:

[0056] Step 1, flocculation and sedimentation

[0057] The sludge in the secondary sedimentation tank in the sewage treatment plant enters the flocculation reaction tank 1 through the pipeline and the first-level sludge pump 11, and the ferric chloride solution is added to the flocculation reaction tank 1 through the dosing device 1, and the dosage is 80kg / ton Dry the sludge, stir for 3-5 minutes, and pump it into the electrolysis machine 2 through the secondary sludge pump 21 after the reaction is complete.

[0058] The above ferric chloride is a flocculant. The flocculant can be one or any combination of two or more of aluminum salts, iron salts, polyaluminum, polyiron, organic polymer flocculants or microbial flocculants, the aluminum salt being aluminum sulfate, aluminum chloride or both The combination of...

Embodiment 3

[0068] A 30,000-ton / day sewage treatment plant produces 600 tons of sludge with a moisture content of 98% per day. The sludge treatment includes the following steps:

[0069] Step 1, flocculation and sedimentation

[0070] The sludge in the secondary sedimentation tank in the sewage treatment plant enters the flocculation reaction tank 1 through the pipeline and the first-level sludge pump 11, and the ferric chloride solution is added to the flocculation reaction tank 1 through the dosing device 1, and the dosage is 200kg / ton Dry the sludge, stir for 3-5 minutes, and pump it into the electrolysis machine 2 through the secondary sludge pump 21 after the reaction is complete.

[0071] The above ferric chloride is a flocculant. The flocculant can be one or any combination of two or more of aluminum salts, iron salts, polyaluminum, polyiron, organic polymer flocculants or microbial flocculants, the aluminum salt being aluminum sulfate, aluminum chloride or both The combination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com