Integrated household kitchen waste composting equipment

A garbage composting and equipment technology, applied in the field of integrated household kitchen waste composting equipment, can solve the problems of slow composting process, inconvenience for operators, and no after-ripening area, so as to improve the fertilizer effect, save labor costs, Effects of Simplified Composting Operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

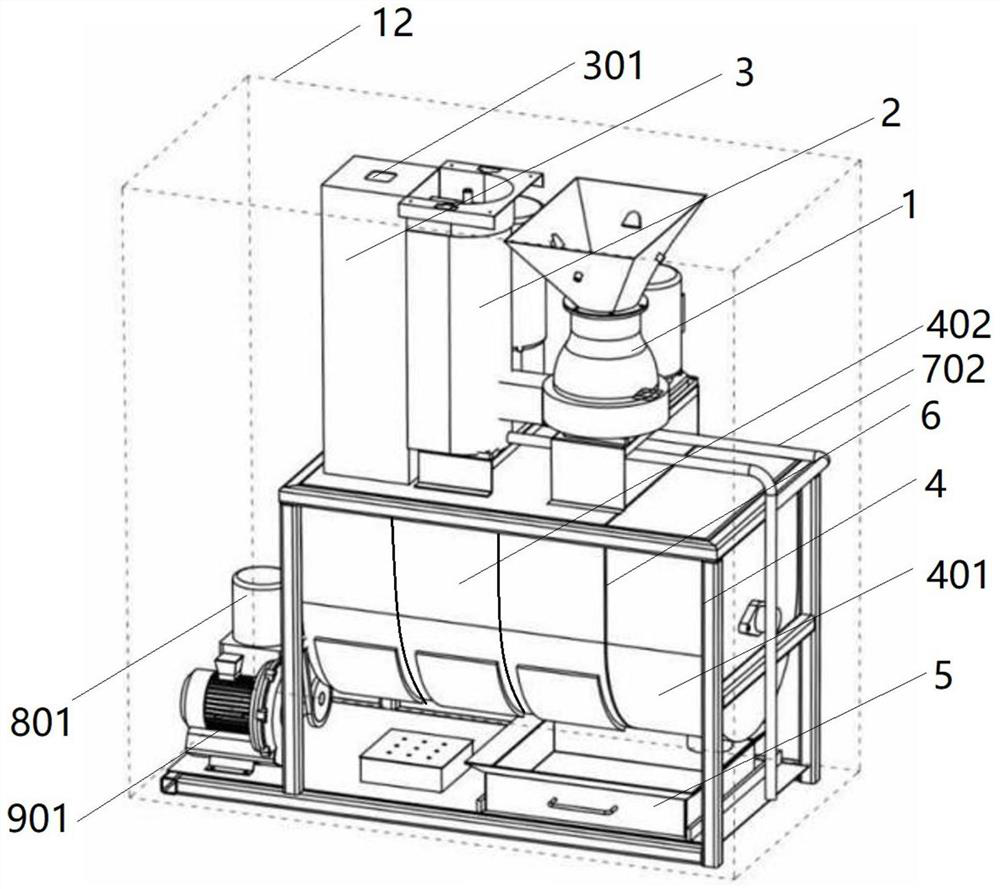

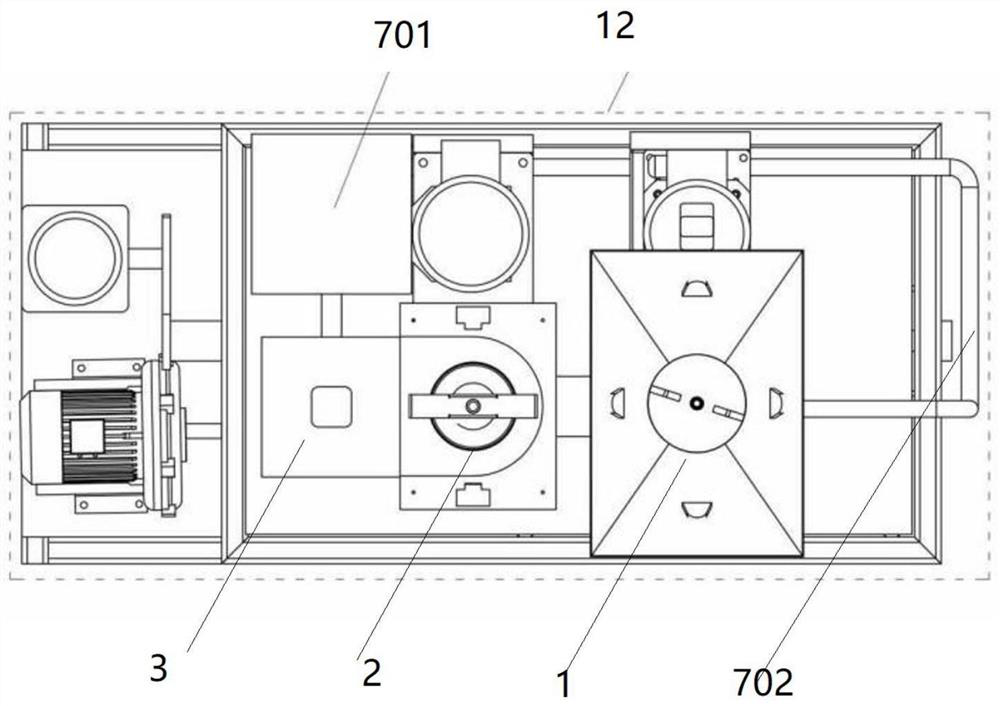

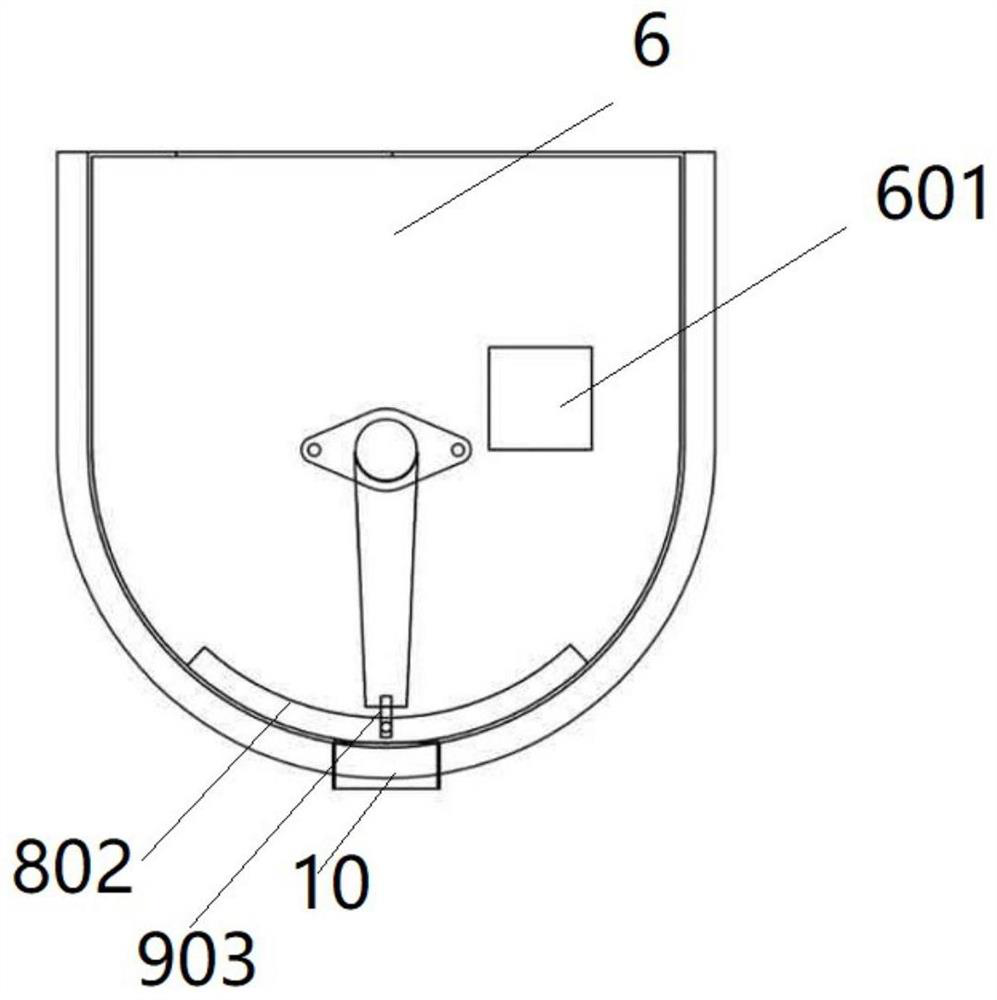

[0043] Such as figure 1 The integrated household kitchen waste composting equipment shown includes:

[0044] Feed crushing device 1; the feed crushing device 1 feeds from the upper port and discharges from the lower port. Food waste enters through the feed port and is discharged from the discharge port after crushing.

[0045] Squeezing device 2: The screwing device 2 is used to feed material from the lower part, move upward after wringing, and discharge from the upper part.

[0046] Feed passage 3, on the described feed passage 3, offer strain inoculation port 301; Port 301, when the material enters from the feed channel 3, the required bacterial agent is added at the same time as required, and the fermentation is carried out together.

[0047] In the biochemical system, the food waste enters the biochemical system through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com