Patents

Literature

38results about How to "Eliminate cumbersome procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

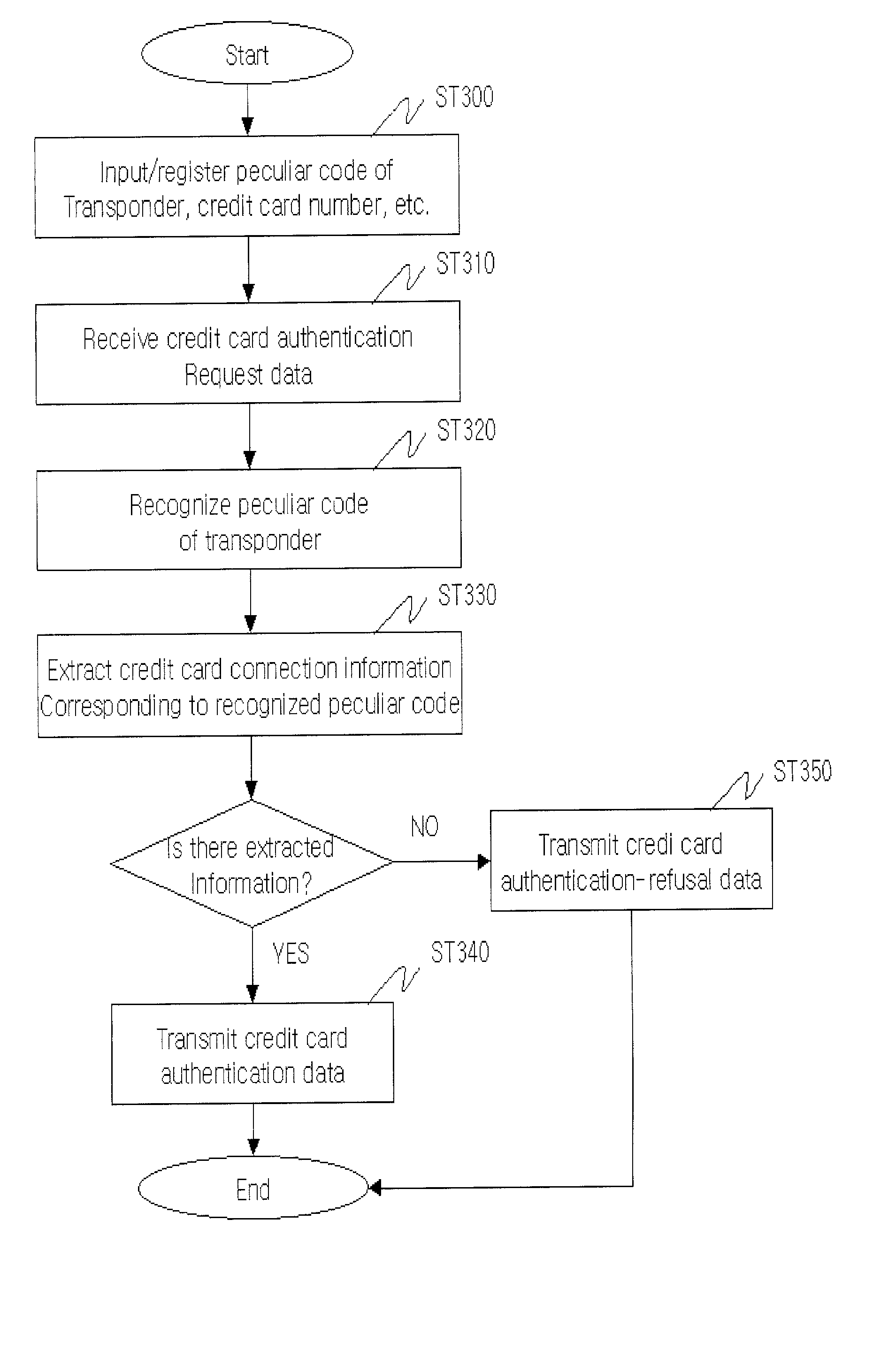

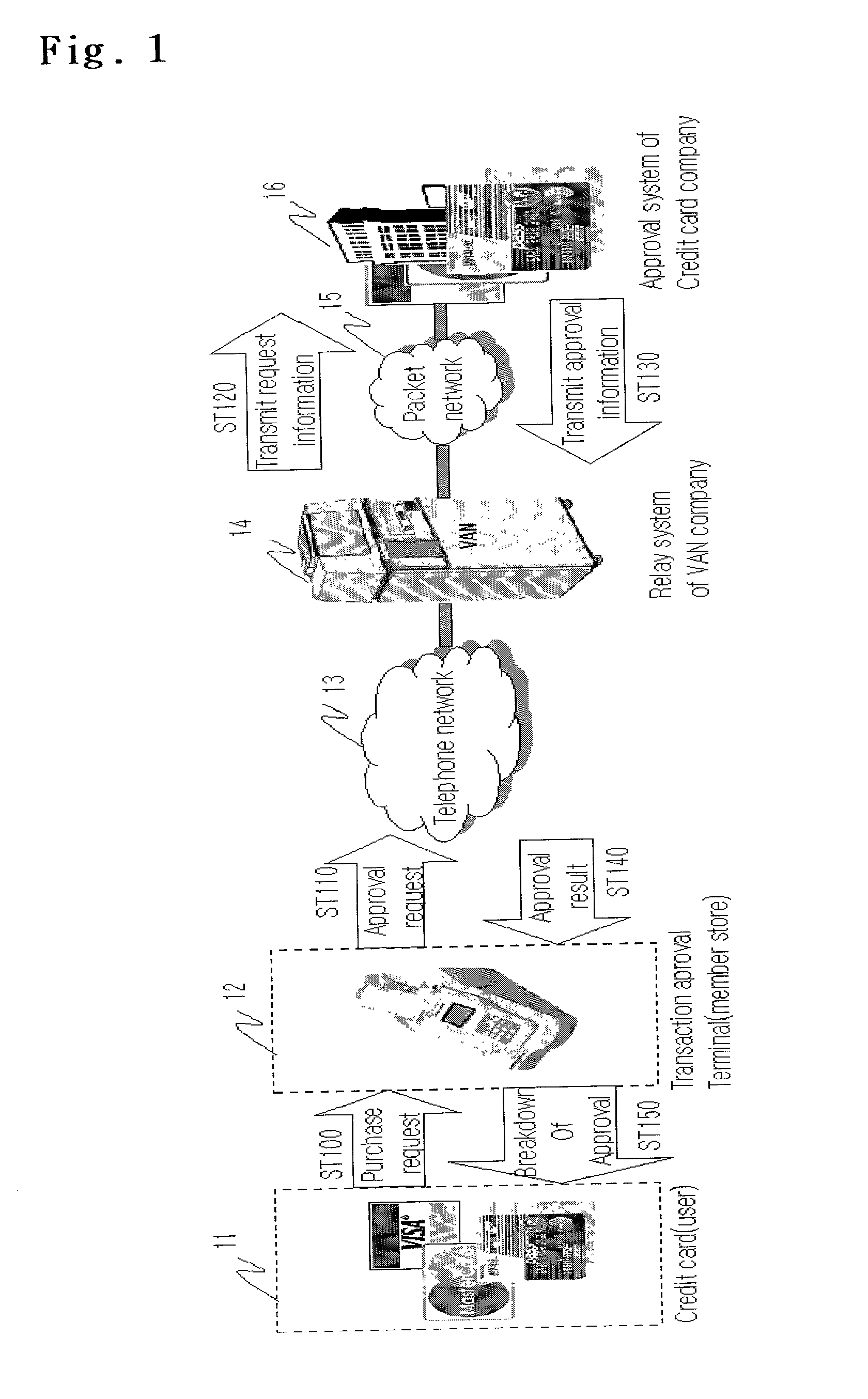

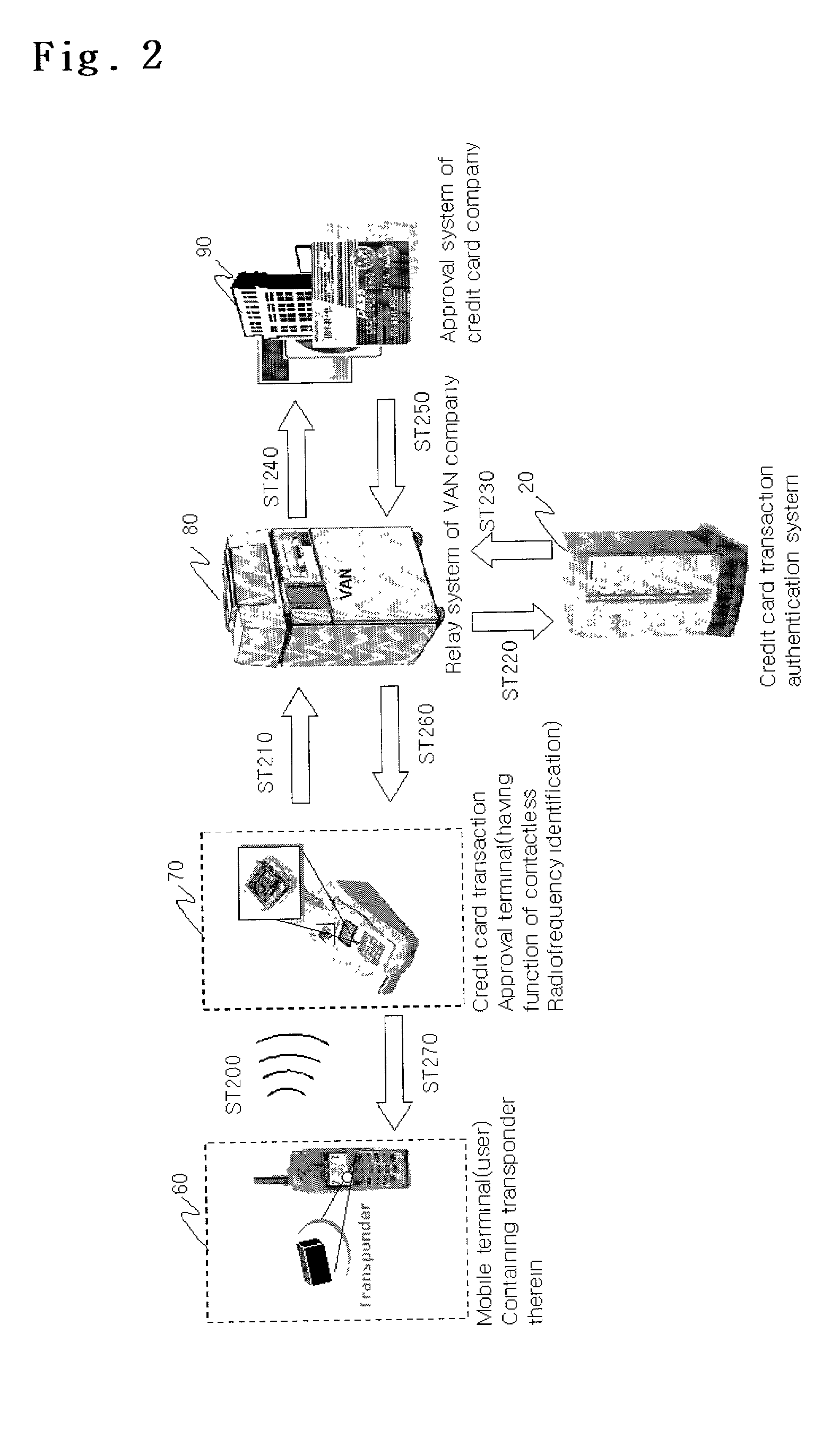

Credit card transaction authentication system and method using mobile terminal

InactiveUS20020152178A1Eliminate cumbersome proceduresAvoid damageFinanceCo-operative working arrangementsCredit cardAuthentication system

The present invention relates to a credit card transaction authentication system and method using a mobile terminal. There is provided a credit card transaction authentication system using a mobile terminal for performing a work of credit card authentication for a relay system of a VAN company connected between an approval system of a credit card company, which can approve a credit card settlement of the prices, and a transaction approval terminal, which requests credit card transaction approval by means of contactless radio-frequency identification for the mobile terminal containing a transponder therein. The present invention provides advantages that a cumbersome procedure in which the credit card should be handed over and taken again by the user upon making the credit card settlement can be eliminated, and stability of credit card information can be enhanced so that a commercial transaction can be briskly made.

Owner:M COMMERCE

Abnormal season flowering artificial des-dormancy method of peony

InactiveCN101248728AOpen and tidyImprove qualityFertilising methodsHorticulture methodsGreenhouseEconomic benefits

An artificial dormancy-removing method for enabling peony to bloom out of season includes: outdoor low-temperature refrigeration, root immersion, potting, watering, outdoor root rearing, greenhouse culture and watering measurement of peony dormant seedlings, the root immersion of the seedlings before potting is the immersion of the root by 50 parts of rooting powder solution; 4-5 years of seedlings are chosen and refrigerated at low temperature of 0-3 DEG C outdoor; in the step of watering after potting, the watering amount is asked to drench the plant; the time of the following outdoor root rearing is chosen to be at the 7-9th nights after potting; the method overcomes the disadvantage of GA3 in promoting flowers in forcing culture of peony and is characterized by time saving, labor saving, low cost and high economic benefits, standardized production, easy popularization, etc.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +1

Multipurpose natural cosmetic containing traditional Chinese medicine component and preparation method thereof

ActiveCN103393586AAvoid harmImprove securityCosmetic preparationsToilet preparationsVitamin CIrritation

The invention discloses a multipurpose natural cosmetic containing a traditional Chinese medicine component and a preparation method thereof and belongs to the technical field of cosmetic preparation. The multipurpose natural cosmetic containing the traditional Chinese medicine component is prepared from the following raw materials by weight percent: 10-20% of lanolin, 1-2 % of tea polyphenol, 1-5% of vitamin C, 1-5% of vitamin E, 5-10% of castor oil, 0.5-2% of papain, 1-8% of aloe juice, 0.2-1.2% of borneol, 1-4% of honey, 0.5-1.5% of citric acid, 8-15% traditional Chinese medicine component and the balance of deionized water. The multipurpose natural cosmetic adopts natural raw materials, the skin affinity is good, irritation is low, the safety is high, and the multipurpose natural cosmetic can be taken orally and externally applied, has the effects of whitening and moisturizing and is radiationproof and sunproof, so that a tedious process of smearing multiple cosmetics everyday is eliminated; besides, the preparation method of the multipurpose natural cosmetic is simple, and the production cost is low.

Owner:山东福瑞达生物股份有限公司

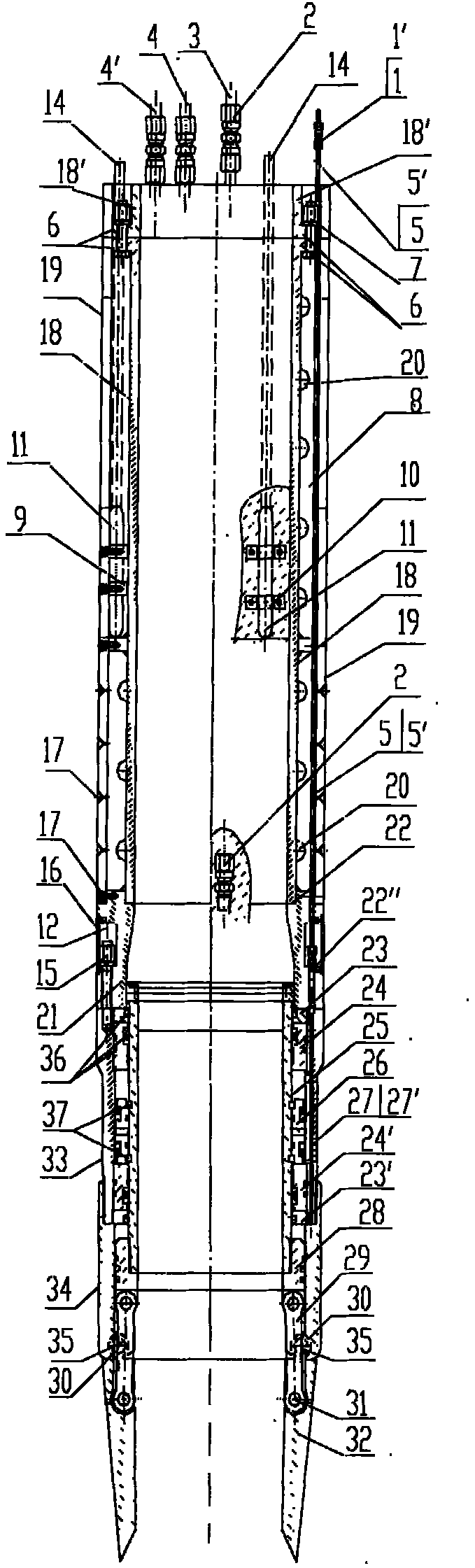

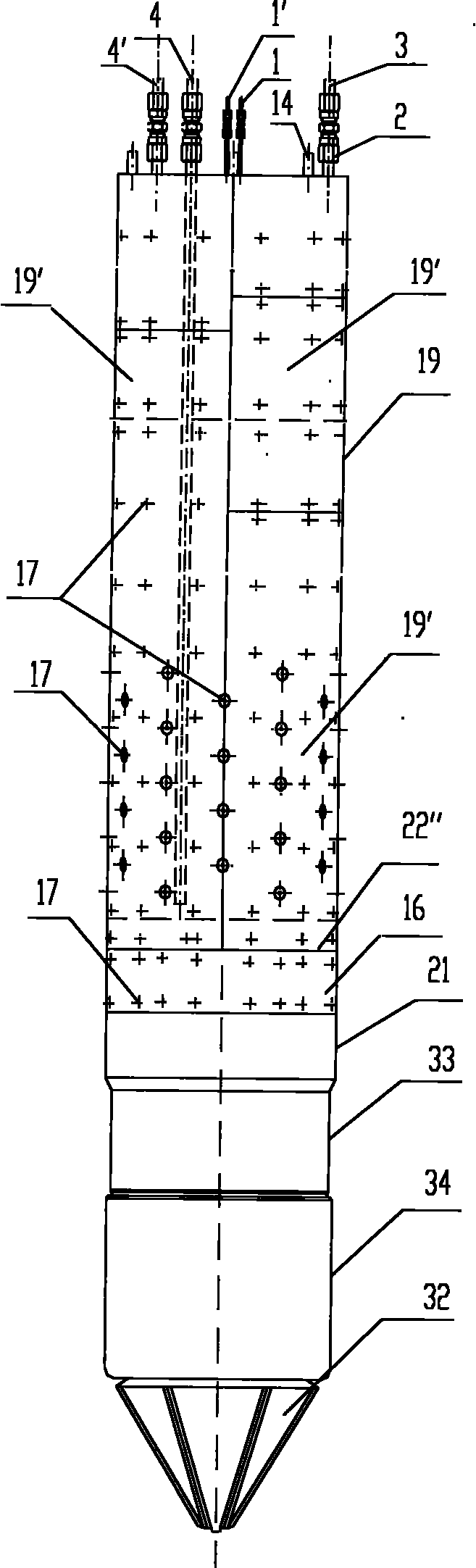

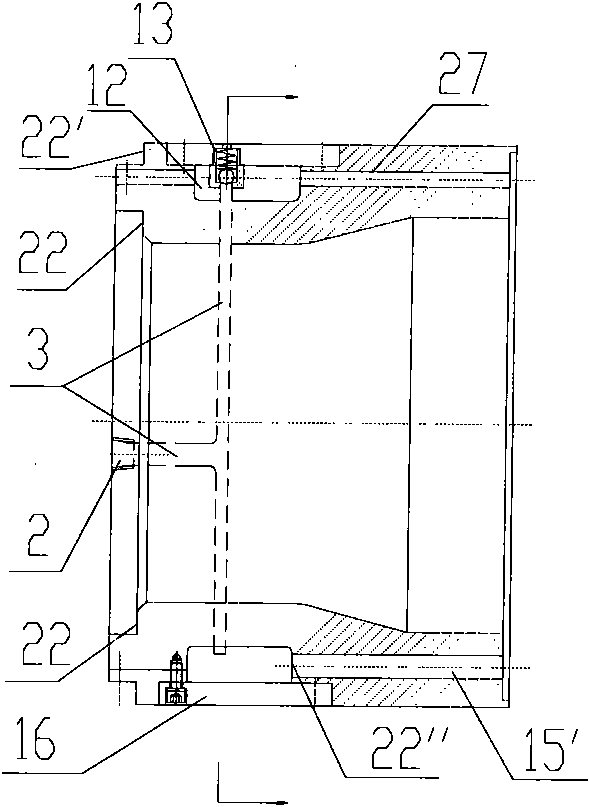

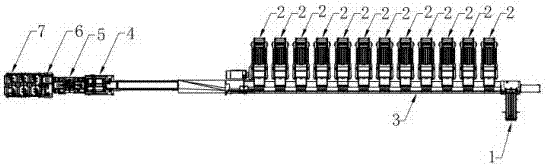

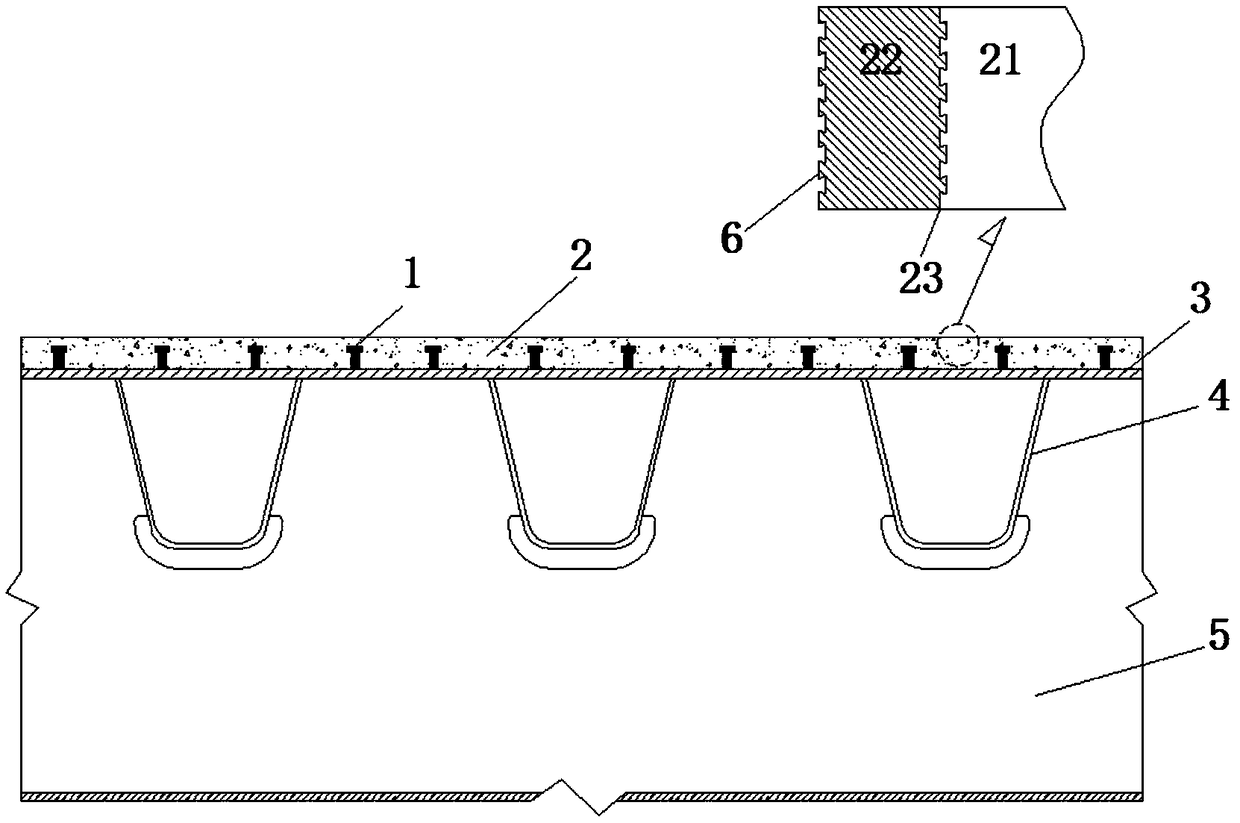

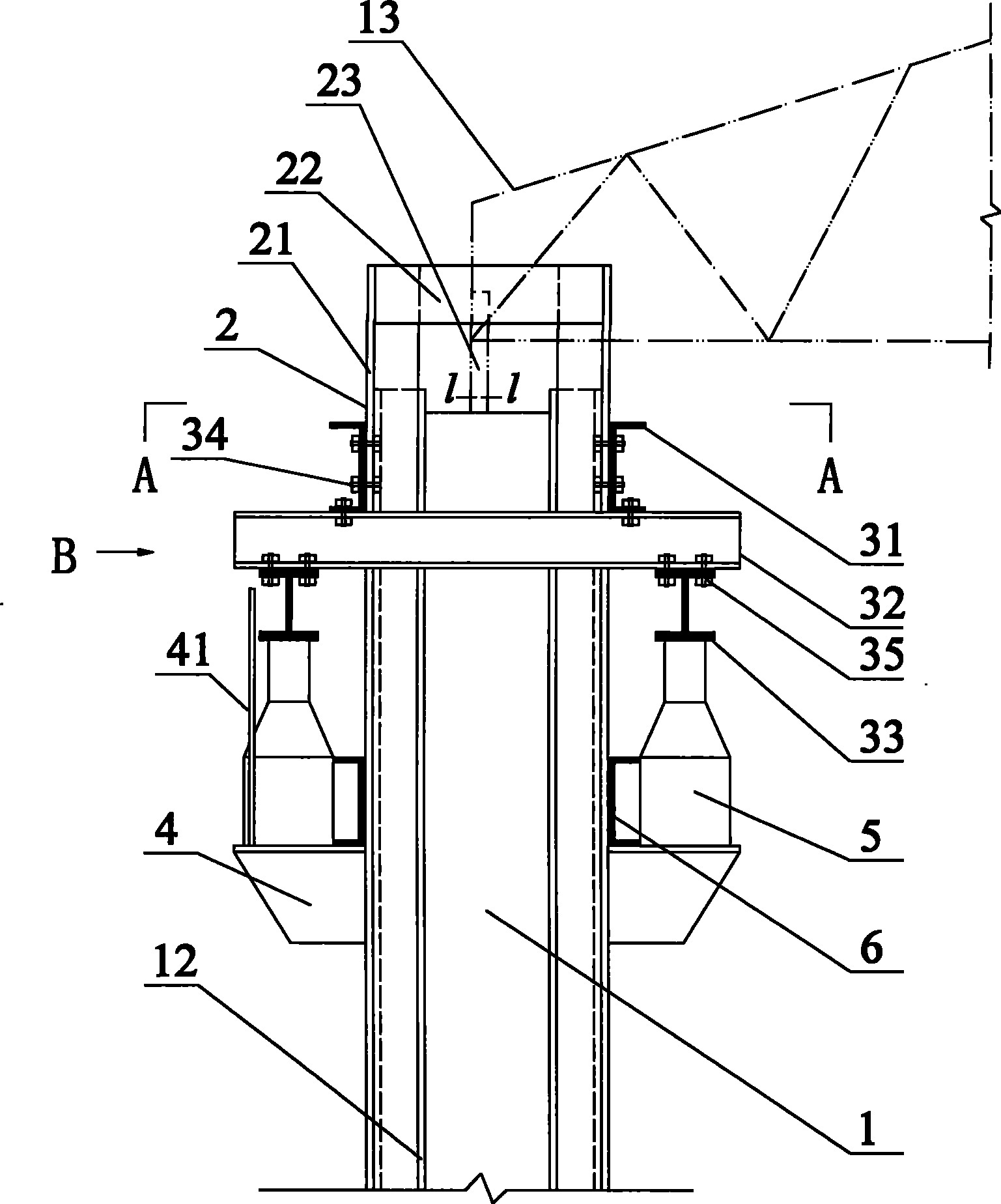

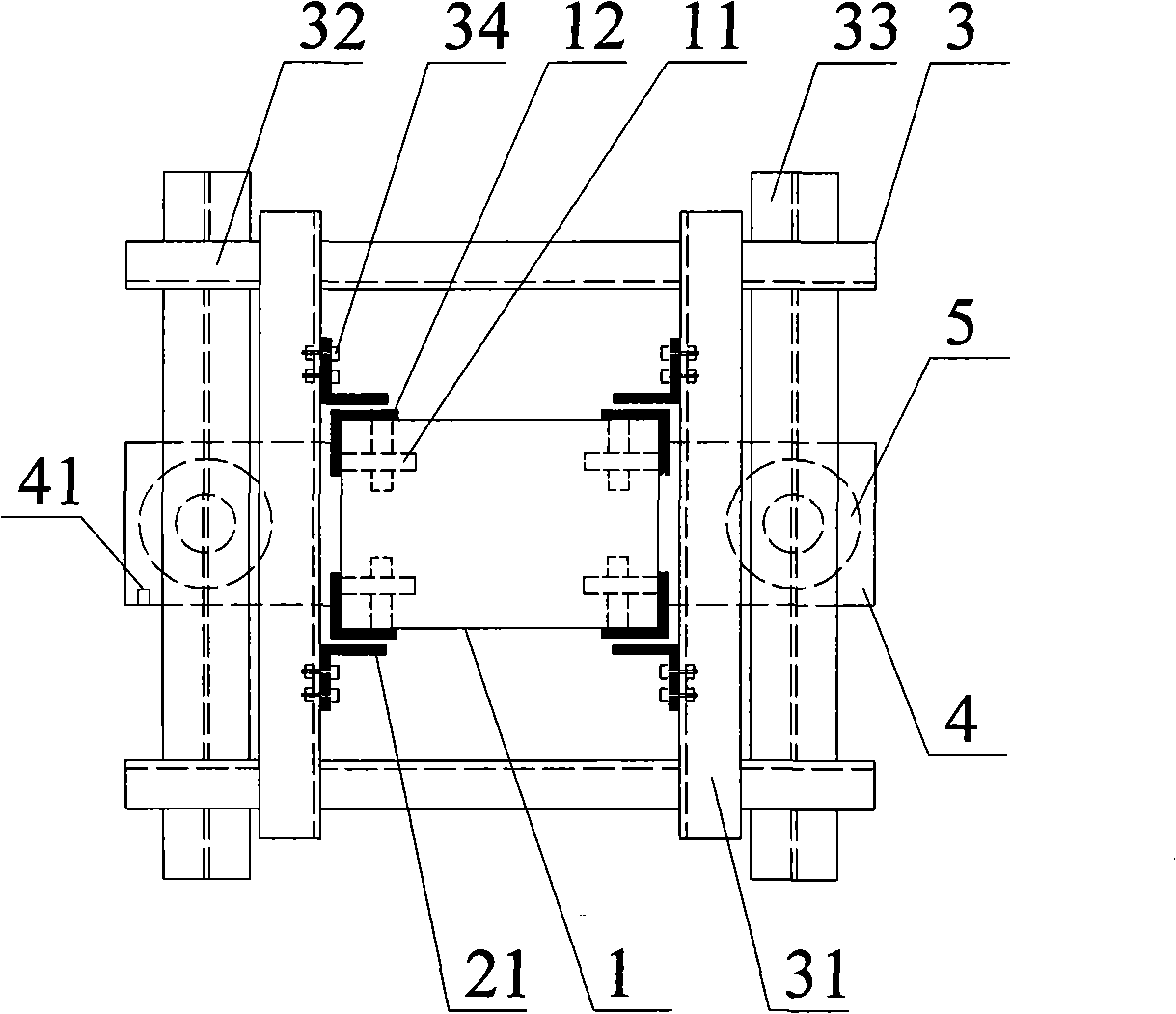

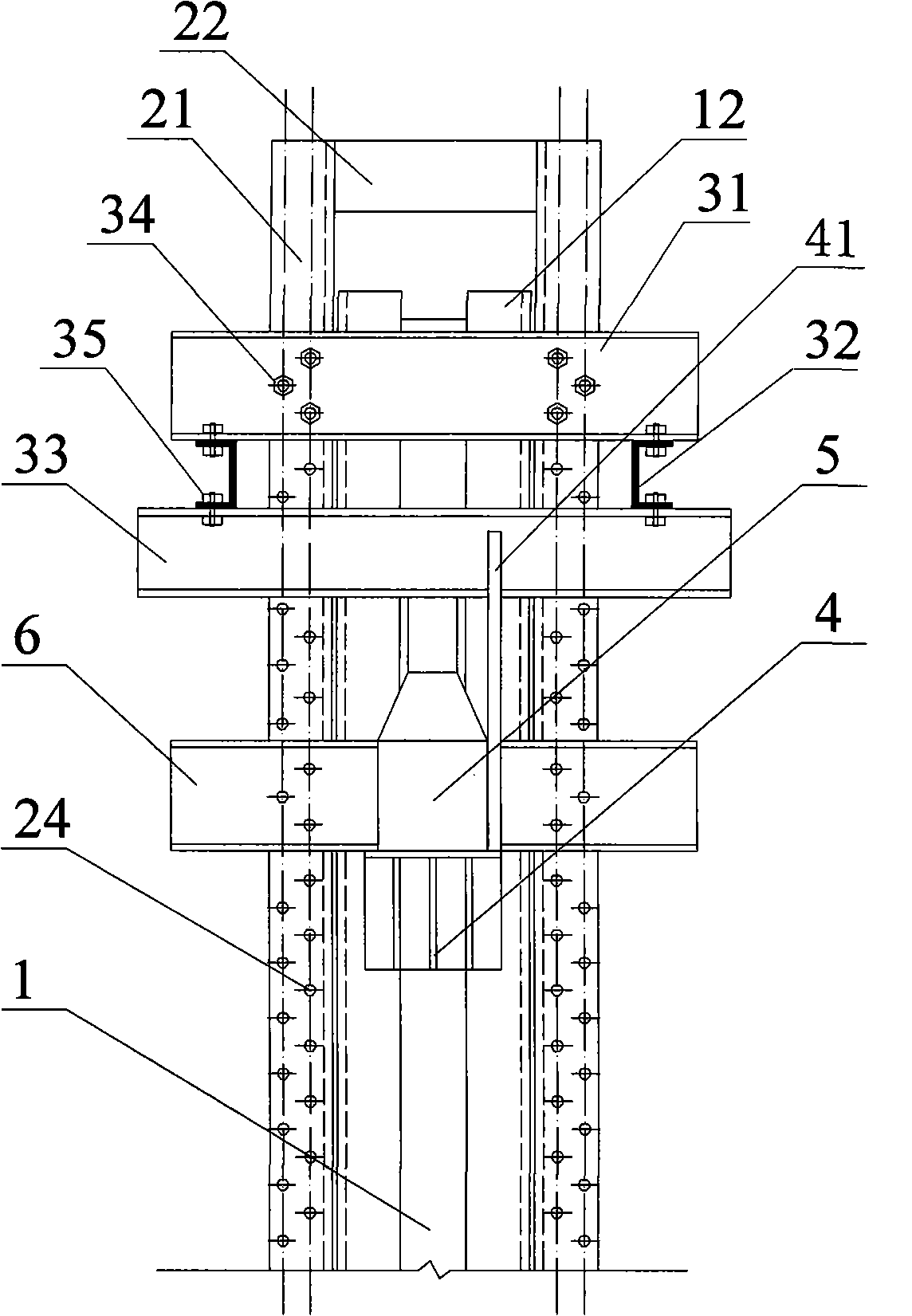

Multi-disk pouring pile one-step molding device and construction method thereof

The invention relates to a pressure grouting and vibrator built-in multi-disk pouring pile one-step molding device and a construction method thereof, belonging to the technical fields of piling machinery and construction of building industry. In the device, by adopting pressure grouting structure and built-in vibrator structure characteristics, a plurality of disk pouring piles are molded in one step by high-pressure guniting and vibrating pile pulling for synchronously constructing concrete vibration tamping extruded expansion through eight procedures of forming pores, expanding the disks several times, carrying out automatic pressure guniting on the peripheral side of a pile body in the pressing process or changing soft soil into higher-strength cement soil character by cement nano slurry, placing a reinforcement cage, pouring cement, carrying out automatic pressure guniting on the peripheral side of the pile body again in the lifting process, vibrating and pulling the pile by the built-in vibrator for synchronously constructing concrete controllable vibration tamping and molding the pile. The invention has simple main body structure, safe and reliable construction operation, simple and convenient construction procedure, high frictional resistance of the soft soil, high bearing capacity of the pile and environmental-friendly construction site.

Owner:QINGDAO JINGLI ENG

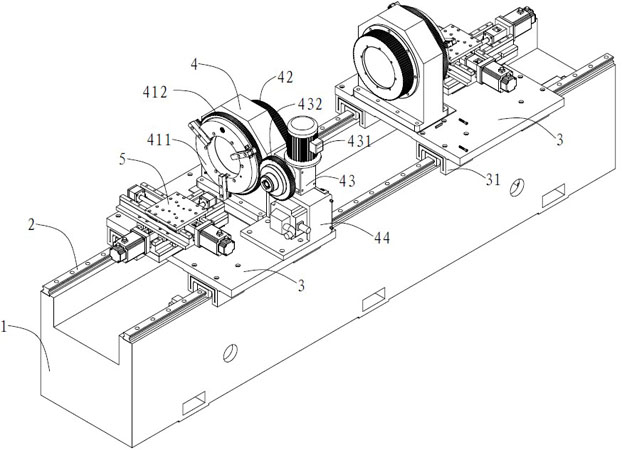

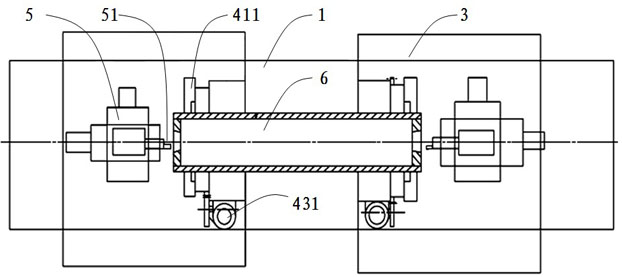

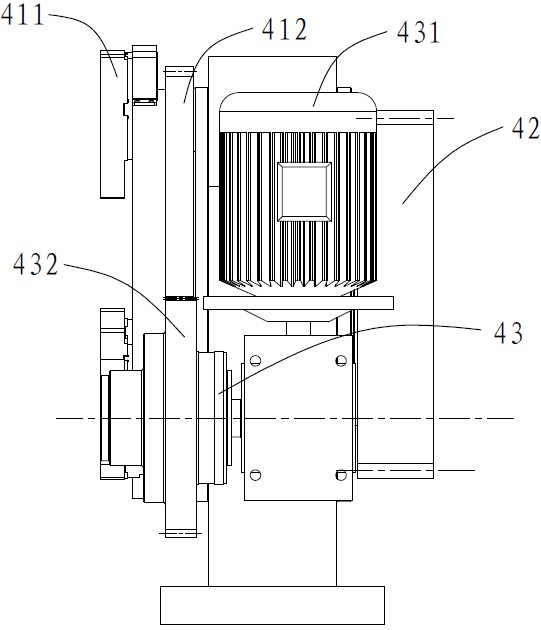

Numerical-control gravure double-head finish-turning machine

InactiveCN101890508AGuaranteed coaxialityEasy to operateTurning machinesNumerical controlElectromagnetic clutch

The invention provides a numerical-control gravure double-head finish-turning machine. Double-guide slipways are arranged on the linear guides of a lathe bed worktable, and the double-guide slipways are connected with the linear guides via linear guide pairs, wherein a spindle box tailstock and a double-coordinate cross-shaped slipway which are arranged on each double-guide slipway are sequentially mounted; the spindle box tailstock is mounted on the inner side relative to each double-guide slipway, a customized chuck is arranged on the outer side of the spindle box tailstock, and a synchronous belt wheel is arranged on the inner side thereof, wherein a bull gear is arranged at the rear part of the customized chuck, and an electromagnetic clutch at the front end of the customized chuck is connected with the bull gear of the customized chuck via a pinion gear on the corresponding side of the customized chuck; and the double-coordinate cross-shaped slipway is mounted on the outer side relative to the double-guide slipway, and a tool rest is arranged on the corresponding side of the customized chuck. The invention can greatly improve the machining efficiency, guarantee the axiality of bores in secondary turning, ensure the high concentricity and good machining quality, facilitate the operation of a user and reduce the requirements for the skill of a worker.

Owner:东莞东运机械制造有限公司

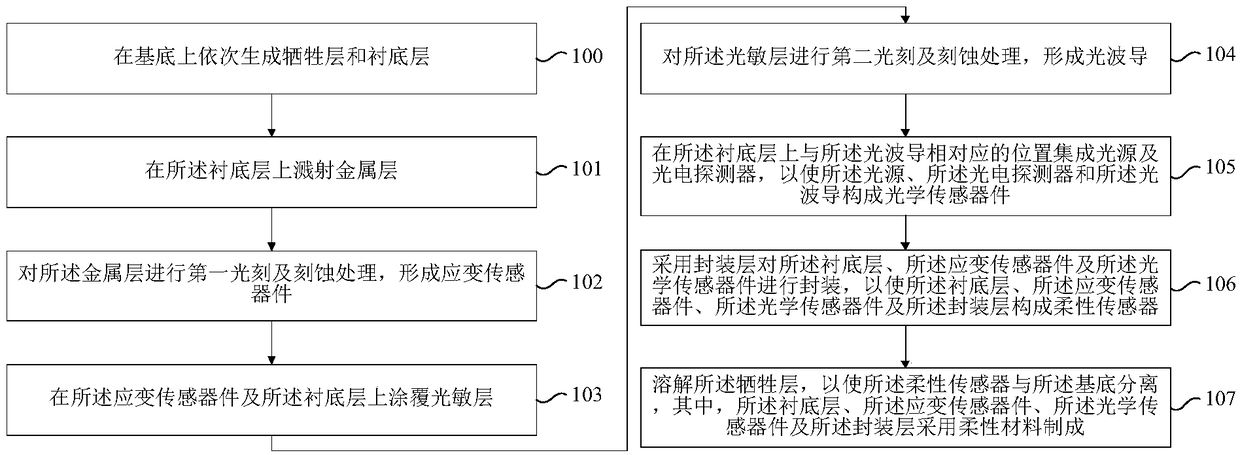

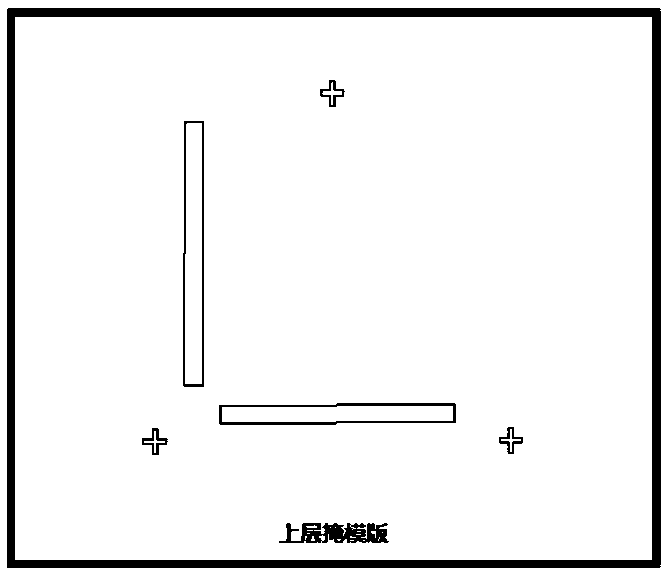

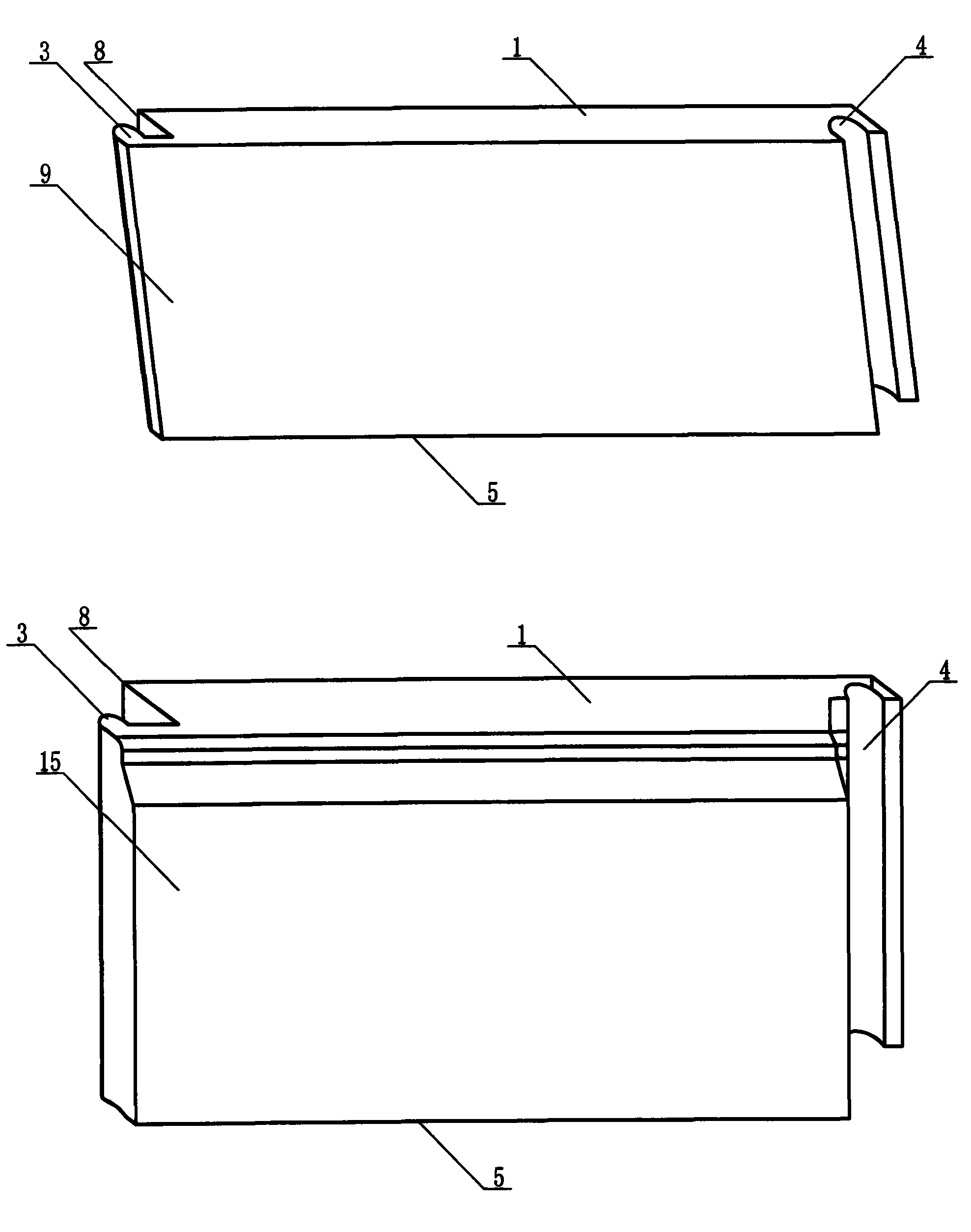

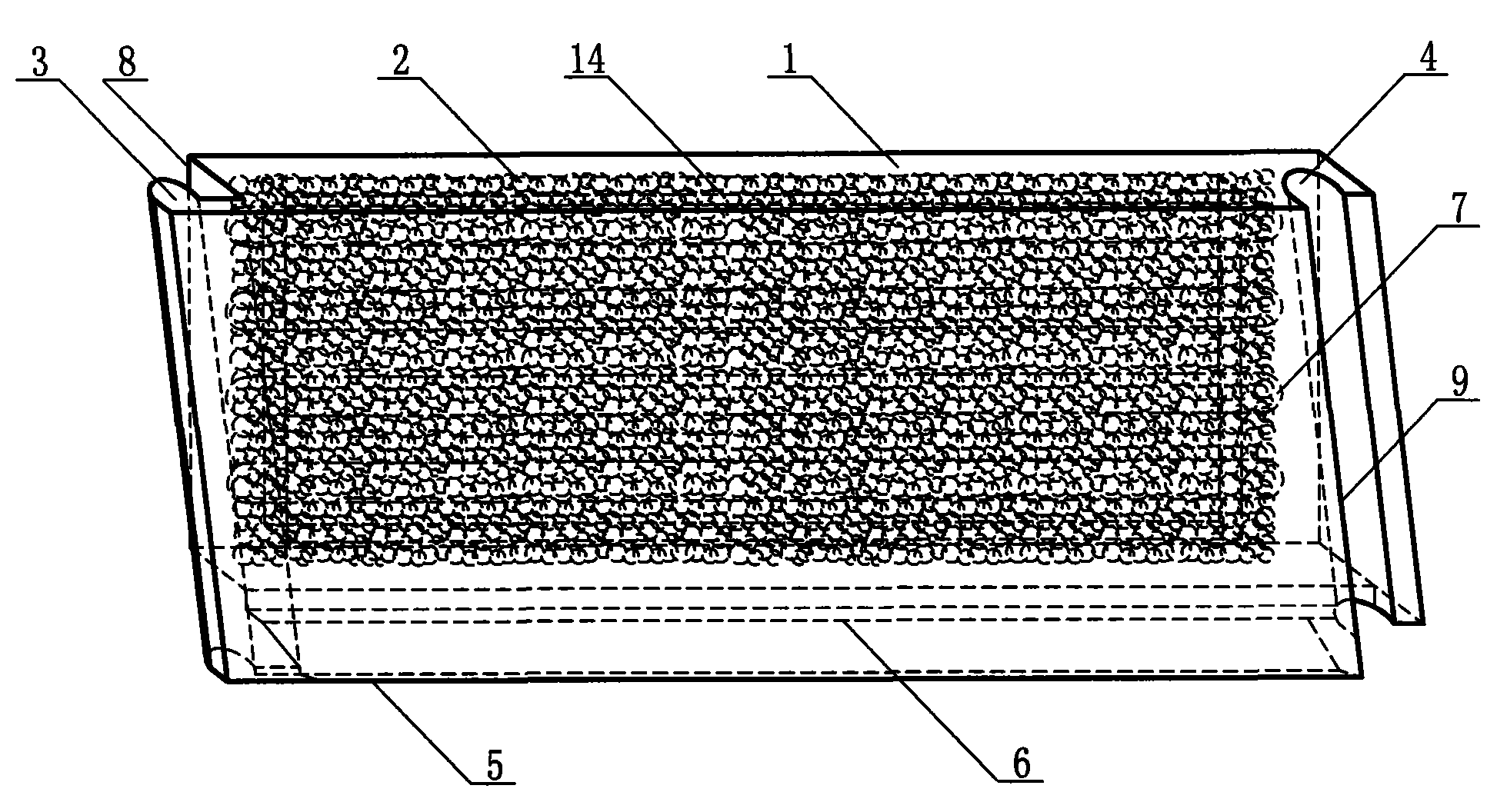

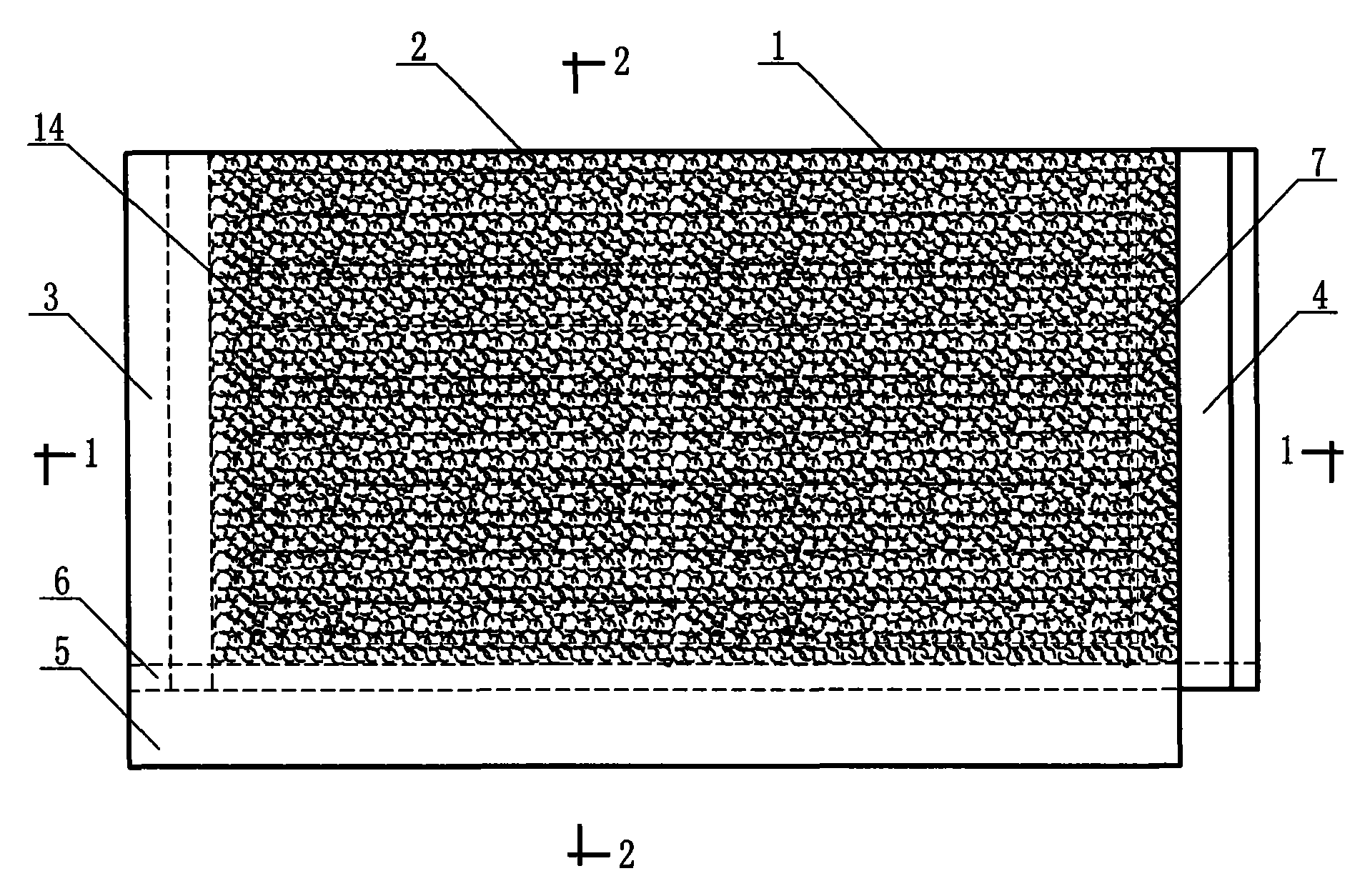

Preparation method of flexible sensor

ActiveCN109059749AEliminate cumbersome procedures and errorsImprove preparation efficiencyElectrical/magnetic solid deformation measurementUsing optical meansPhysicsStrain sensor

The invention relates to a preparation method of a flexible sensor. The preparation method comprises the steps of sequentially generating a sacrificial layer and a substrate layer on a base; sputtering a metal layer on the substrate layer; performing first photo-etching and etching processing on the metal layer to form a strain sensor device; coating a photosensitive layer on the strain sensor device and the substrate layer; performing second photo-etching and etching processing on the photosensitive layer to form an optical waveguide; integrating a light source and a photoelectric detector ata position, corresponding to the optical waveguide, on the substrate layer so that the light source, the photoelectric detector and the optical waveguide form the optical sensor device; packaging thesubstrate layer, the strain sensor device and the optical sensor device by use of a packaging layer so that the substrate layer, the strain sensor device, the optical sensor device and the packaginglayer form the flexible sensor; and dissolving the sacrificial layer so that the flexible sensor and the base are separated. According to the reparation method of the flexible sensor, the strain sensor device and the optical sensor device with complicated double-layer structures are molded once through large-range photo-etching, and the preparation efficiency of the flexible sensor is improved.

Owner:TSINGHUA UNIV

Spleen strengthening and stomach nourishing lotus seed pudding and preparation method thereof

InactiveCN102885299AExtended shelf lifeHas the effect of invigorating the spleen and nourishing the stomachFood preparationBiotechnologyNutrition

The invention relates to a spleen strengthening and stomach nourishing lotus seed pudding and a preparation method thereof. The spleen strengthening and stomach nourishing lotus seed pudding is prepared from lotus seed, tuckahoe, white lablab bean and gorgon fruit. The preparation method is characterized by comprising the following steps of: pulping the raw materials; heating; molding by casting; cooling; automatically demolding; drying; and then packaging. A complex process of wrapping with glutinous rice paper is saved; and the spleen strengthening and stomach nourishing lotus seed pudding has the advantages of simple process, long quality guarantee period, rich nutrition and spleen strengthening and stomach nourishing effects and suitability for being eaten by people with weak spleen and stomach function.

Owner:JIANGXI SHI FANG SHI FANG CHINESE MEDICINE FOOD

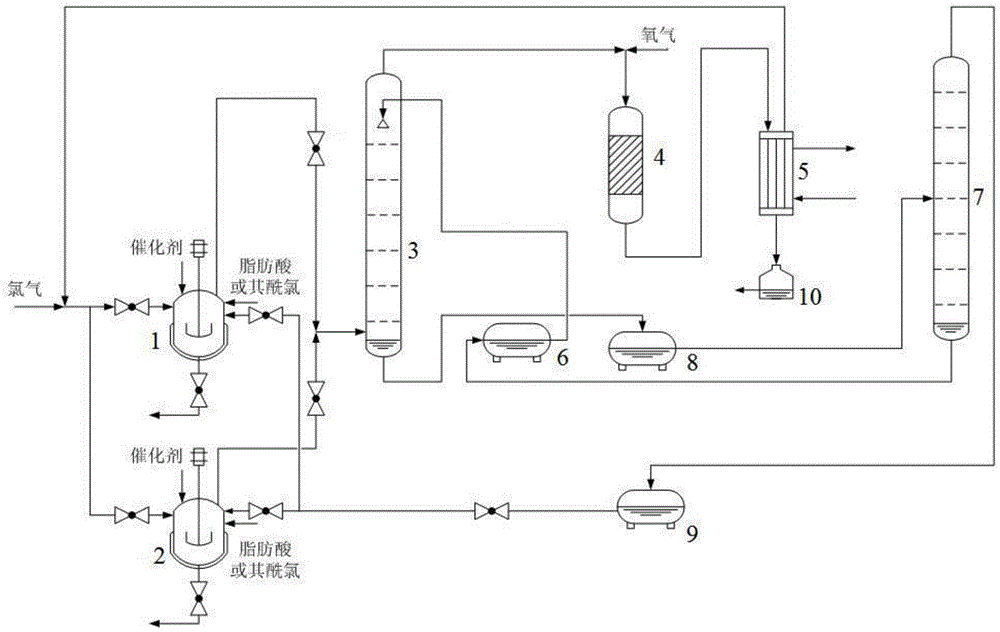

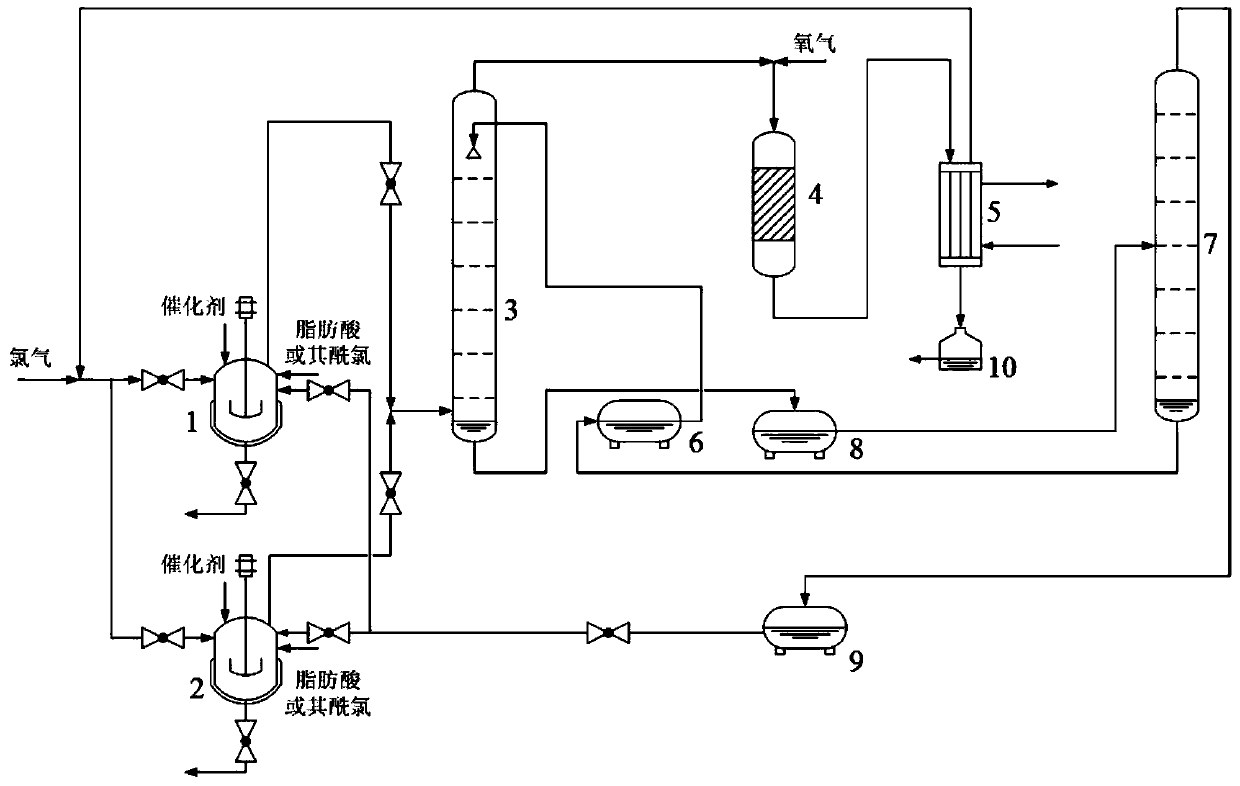

Method and system for recycling by-product hydrogen chloride in fatty acid or fatty acyl chloride chlorination production process

ActiveCN105480948AEliminate cumbersome proceduresSimple process routeChlorine/hydrogen-chloride purificationOrganic compound preparationCatalytic oxidationOxygen

The invention discloses a method for recycling the by-product hydrogen chloride in the fatty acid or fatty acyl chloride chlorination production process. The method includes the steps that the by-product hydrogen chloride waste gas generated in a chlorination reaction of fatty acid or acyl chloride thereof is introduced into a hydrogen chloride purification tower from the lower portion of the hydrogen chloride purification tower and makes countercurrent contact with absorption liquid in the hydrogen chloride purification tower, and organic impurities in the hydrogen chloride waste gas are adsorbed and removed with the absorption liquid; the hydrogen chloride waste gas obtained after absorption purification and oxygen are subjected to a catalytic oxidation reaction under the action of an oxidation catalyst; mixed gas obtained after the oxidation reaction of hydrogen chloride passes through chilled brine, and the mixed gas obtained after chilled dehydration is subjected to catalytic chlorination with fresh chlorine and fatty acid or acyl chloride thereof directly so as to produce chlorinated aromatic hydrocarbons; the hydrogen chloride waste gas containing organic impurities enters the hydrogen chloride purification tower from the lower portion of the hydrogen chloride purification tower to be subjected to absorption purification again. By means of the method, the tedious processes of conducting compression chilling and the like for separating oxygen after hydrogen chloride is oxidized are omitted, the technological route is shortened, and the equipment investment cost can be greatly reduced.

Owner:NANTONG TIANSHI CHEM

Anti-cancer lotus seed pastry capable of strengthening spleen and replenishing qi and preparation method thereof

InactiveCN103876203AHas the effect of invigorating the spleen, invigorating qi and anti-cancerEliminate cumbersome proceduresAntineoplastic agentsFood ingredient functionsBiologyGinseng

The invention discloses an anti-cancer lotus seed pastry capable of strengthening spleen and replenishing qi and a preparation method thereof. The anti-cancer lotus seed pastry capable of strengthening spleen and replenishing qi is prepared from lotus seeds, astragalus membranaceus, white atractylodes rhizome, dried tangerine or orange peel, white lablab bean, ginseng and tuckahoe. The preparation method disclosed by the invention is characterized by comprising the steps of pulping the raw materials and then heating and pouring for molding, cooling and then automatically demolding, drying and then packaging. Therefore, a complex process of packaging glutinous rice paper is saved; the anti-cancer lotus seed pastry capable of strengthening spleen and replenishing qi has the advantages of simple process, long guarantee period, rich nutriments and capability of strengthening spleen, replenishing qi and resisting cancers.

Owner:于海霞

Health preservation lotus seed cake and preparation method thereof

InactiveCN104856041AEliminate cumbersome proceduresSimple processFood preparationSugarCrataegus pinnatifida

The invention discloses a health preservation lotus seed cake and a preparation method thereof. The health preservation lotus seed cake is prepared from the following raw materials in parts by weight: 50-75 parts of lotus seeds, 20-40 parts of poria, 10-20 parts of Chinese yam, 75-100 parts of glutinous rice, 50-80 parts of old rice, 1-3 parts of white granulated sugar, 10-20 parts of Chinese dates, 10-20 parts of fruits of Chinese wolfberry, 10-20 parts of haw and 10-20 parts of walnut kernel. According to the health preservation lotus seed cake, the content of traditional Chinese medicine materials is moderate, the impact to the taste of the product is low, and the taste of original food is furthest maintained; the health preservation lotus seed cake has the advantages that the mouth feel while eating is good, the pungent odor of the medical materials is light, and the like.

Owner:刘发元

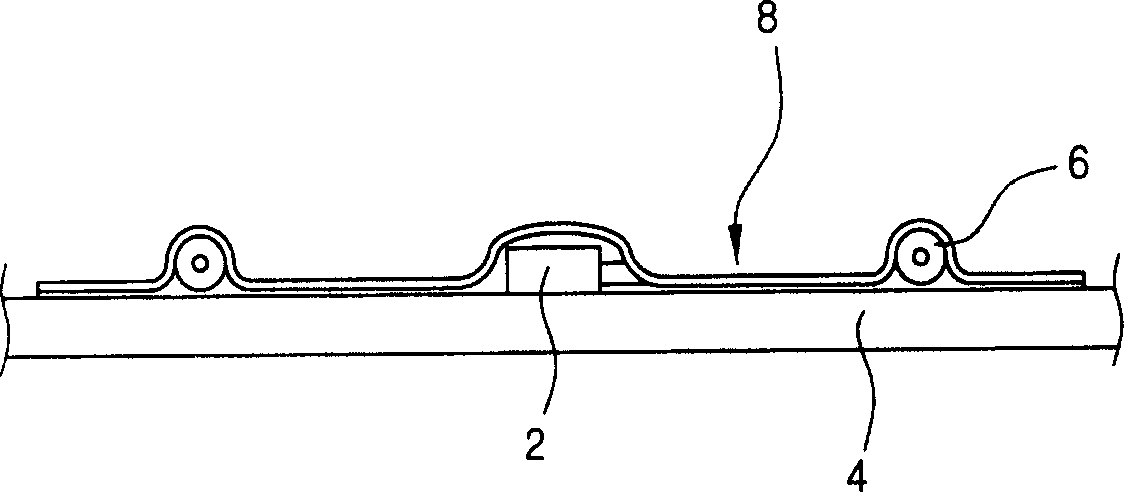

Anti-seepage vacuum insulation outer wall facing tile

InactiveCN103410283AImprove smoothnessEliminate local hollowingCovering/liningsBrickThermal insulation

The invention relates to building materials in the building energy-saving waterproof field, in particular to an anti-seepage vacuum insulation outer wall facing tile. According to the anti-seepage vacuum insulation outer wall facing tile, a flat face brick is additionally arranged on the basis of the technology of 'anti-seepage insulation facing tile' with the application number of 201210074941.0, and meanwhile a vacuum chamber is additionally formed in a brick body. The top end of a paved facing tile presses against the lower portion of a lower end water dripping olecranon-shaped mouth, and a left side tile tenon right falls in a right side falling groove, so that the facing tiles can be covered by one another, joint seams among the facing tiles will not be exposed outside, and rain can be prevented from entering a wall body from the joint seams. Due to the facts that the seams among the facing tiles are not squeezed any more when the facing tiles are paved, and the seams are not scraped outwardly any more after the facing tiles are paved, when temperature rises or falls, gaps for allowing the facing tiles to stretch out and draw back exist when the facing tiles are in the condition of expanding with heat and contracting with cold, and therefore local hollowing caused by squeezing of expanding with heat and contracting with cold can be avoided. In addition, air holes and the vacuum chamber are formed in each facing tile body, so that not only is the range of expanding with heat and contracting with cold of the outer wall facing tile reduced, but also the coefficient of heat conductivity of the outer wall facing tile is greatly reduced. Therefore, the purpose of thermal insulation is achieved.

Owner:宋兰芳 +2

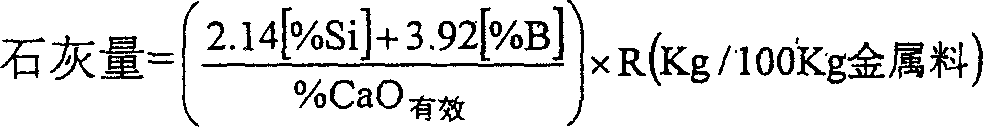

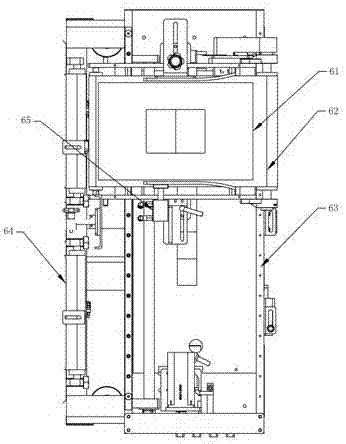

Method for smelting boron steel directly from pig iron containing boron

InactiveCN1296504CEliminate cumbersome proceduresReasonable workmanshipManufacturing convertersBoronAlloy

This invention relates to prodn. of boron steel by using boron pig iron as raw material. The boron-contg. pig iron, produced from blast-furnace from boron iron ore, is used as raw material, proceeding sulphur-removing by using calcium carbonate, lime or calcium carbide or their composition as sulphur-removing agent, then feeding in a convertor. The prodn. procedure are as follows: (1). charging the above-said molten iron of 50-70% wt. parts and the rest being waste steel or iron ore, (2). adding slag-formation agent contg. CaO and small amount of iron scale and MgO at temp. of 1400 deg.C and maintanied at 1400 deg.C, (3). feeding-in oxygen for 20-25 min, with the feeding rate of 2.5-3.5 NM3 / t.min and (4). finishing point control; steel-tapping temp. is 1550-1580 deg.C, and adding manganese iron alloy or silicon manganese alloy, to make the content of manganese being not less than 0.6% and the content of boron being of 0.001-0.006% (wt). Advantages are: even distribution of boron, stable steel properties.

Owner:NORTHEASTERN UNIV

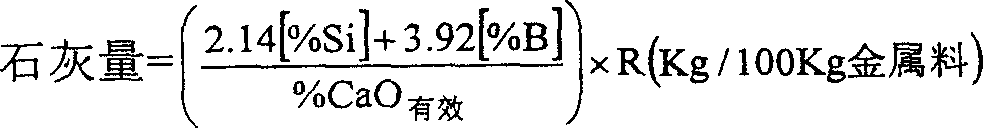

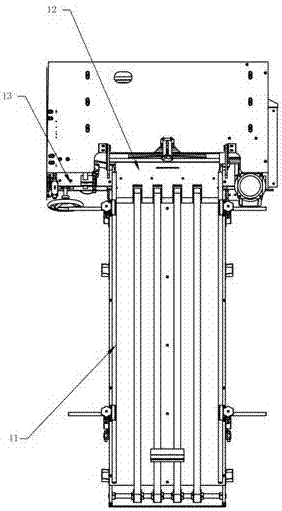

Fully automatic production line for special-shaped paperboard books

PendingCN108002094AReduce the number of settingsEliminate cumbersome proceduresPile receiversConveyor partsEngineeringFully automatic

The invention discloses a fully automatic production line for special-shaped paperboard books. The fully automatic production line for the special-shaped paperboard books comprises a book closing device, multiple groups of local gluing devices, a turning device, a stacking-storing device, a left-right shunt mechanism, and a six-head flat-pressing air cylinder book-pressing device; and right mounted devices are arranged between the book closing device and the tail end of each local gluing device, the right mounted devices comprise right mounted device flag-pushing guide rails which are used forflag-pushings and can drive the flag-pushings move in the horizontal direction, the book closing device comprises book closing conveyor belts, book closing panels flushed with the right mounted devices, and book limiting gear levels, the right mounted device flag-pushing guide rails extend into the book closing panels, and intervals for a sheet of paperboard book to pass through are reserved between the book limiting gear levels and the book closing panels.

Owner:佛山市金页盈信智能机械有限公司

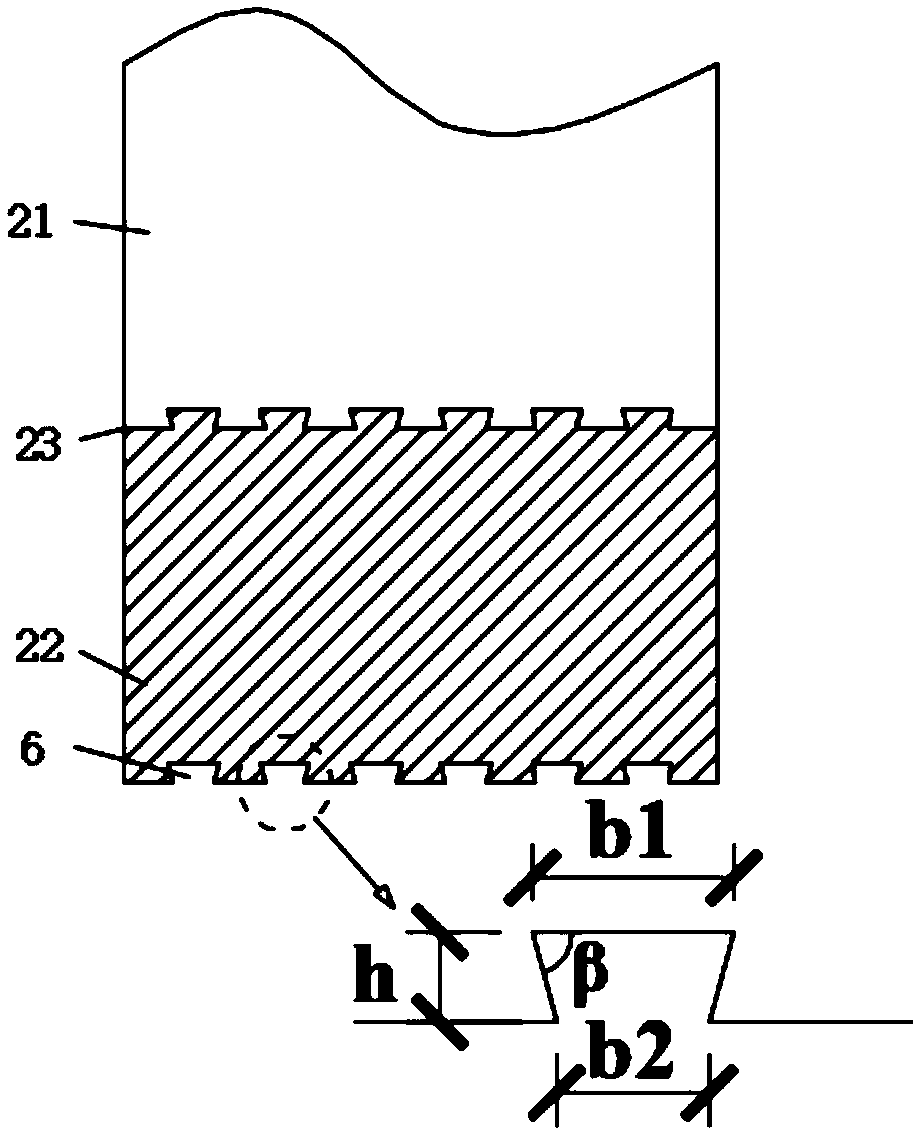

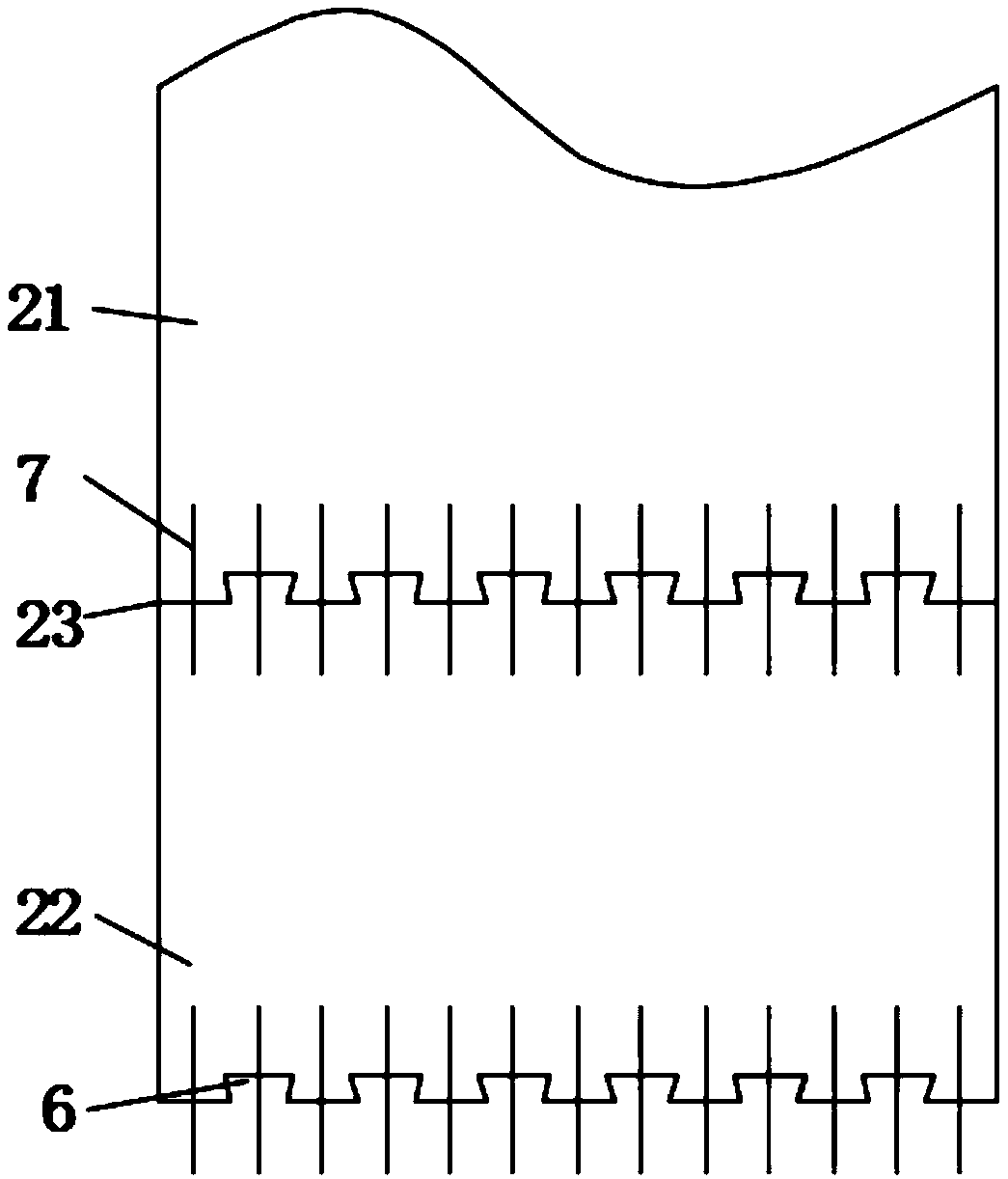

An unreinforced steel-UHPC composite bridge deck structure and a construction method thereof

PendingCN109208474ALow raw material costImprove carrying capacityBridge structural detailsBridge erection/assemblyFlat jointBridge deck

An unreinforced steel-UHPC composite deck structure comprises a UHPC bridge deck, an orthotropic steel bridge deck and a connecting bolt, and that main part of the UHPC bridge deck is not provided with stress reinforcement and structural reinforcement. When the UHPC bridge deck is cast in-situ in sections, the joint part adopts a keytooth bite joint or a flat joint with close reinforcement, and the keytooth bite joint is matched with a metal corrugated sleeve and a joint thread steel bar. The invention also discloses a construction method of the composite bridge deck structure. This steel-UHPCcomposite bridge deck structure is simple, which significantly reduces the raw material cost of composite bridge deck structure, reduces the construction human cost, and shortens the construction period, and the overall bearing capacity and fatigue resistance of bridge deck meet the stress requirements. the unreinforced steel-UHPC composite bridge deck structure is suitable for fatigue strengthening of orthotropic steel bridge deck and rigid deck paving of new steel bridge.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

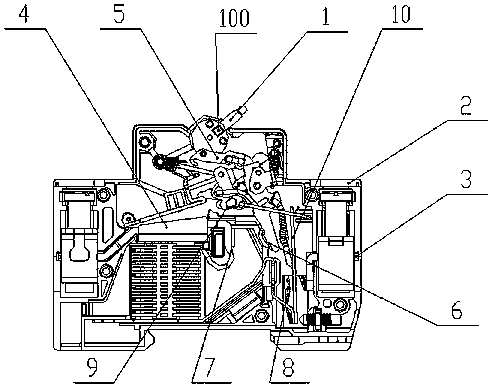

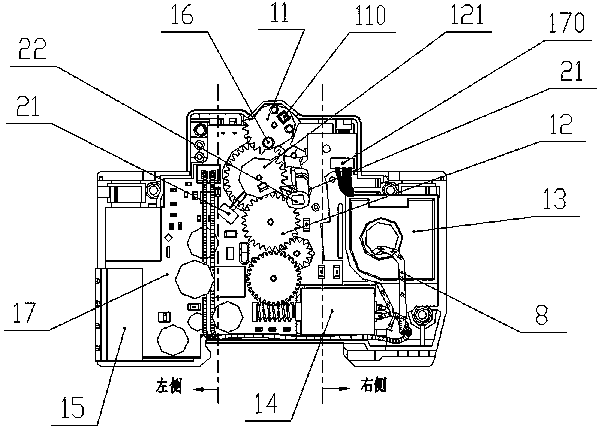

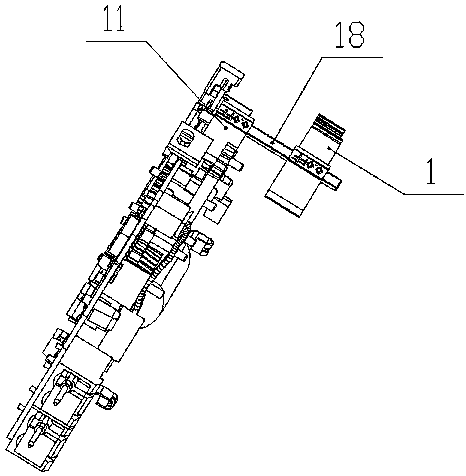

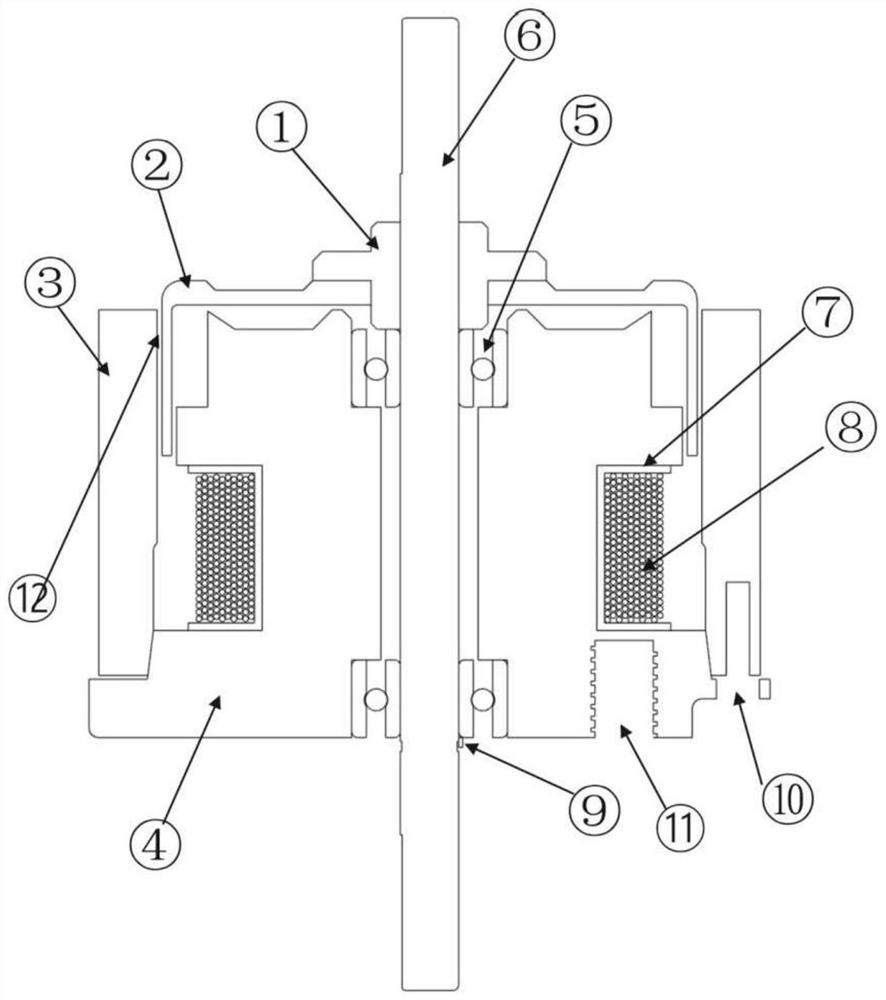

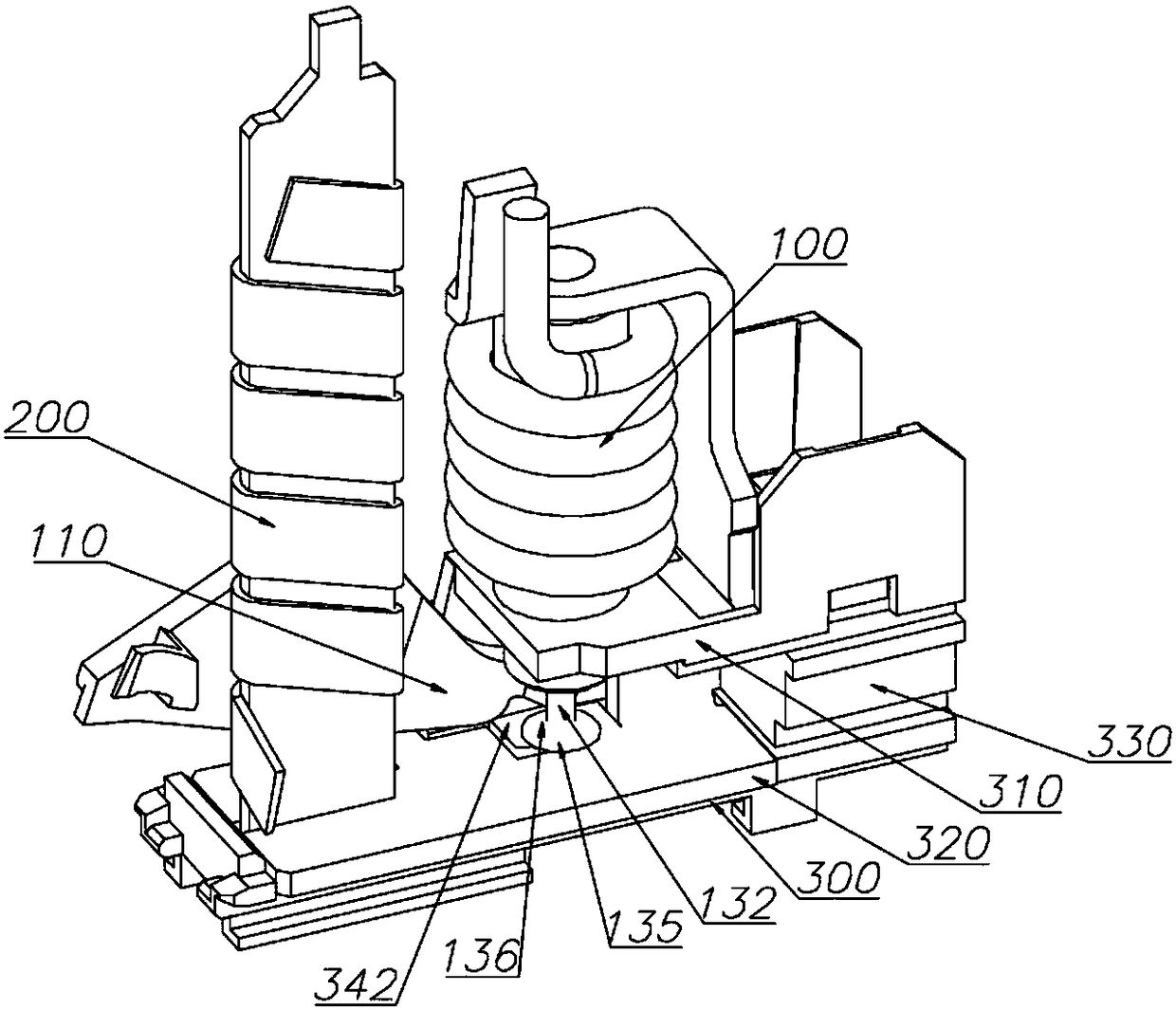

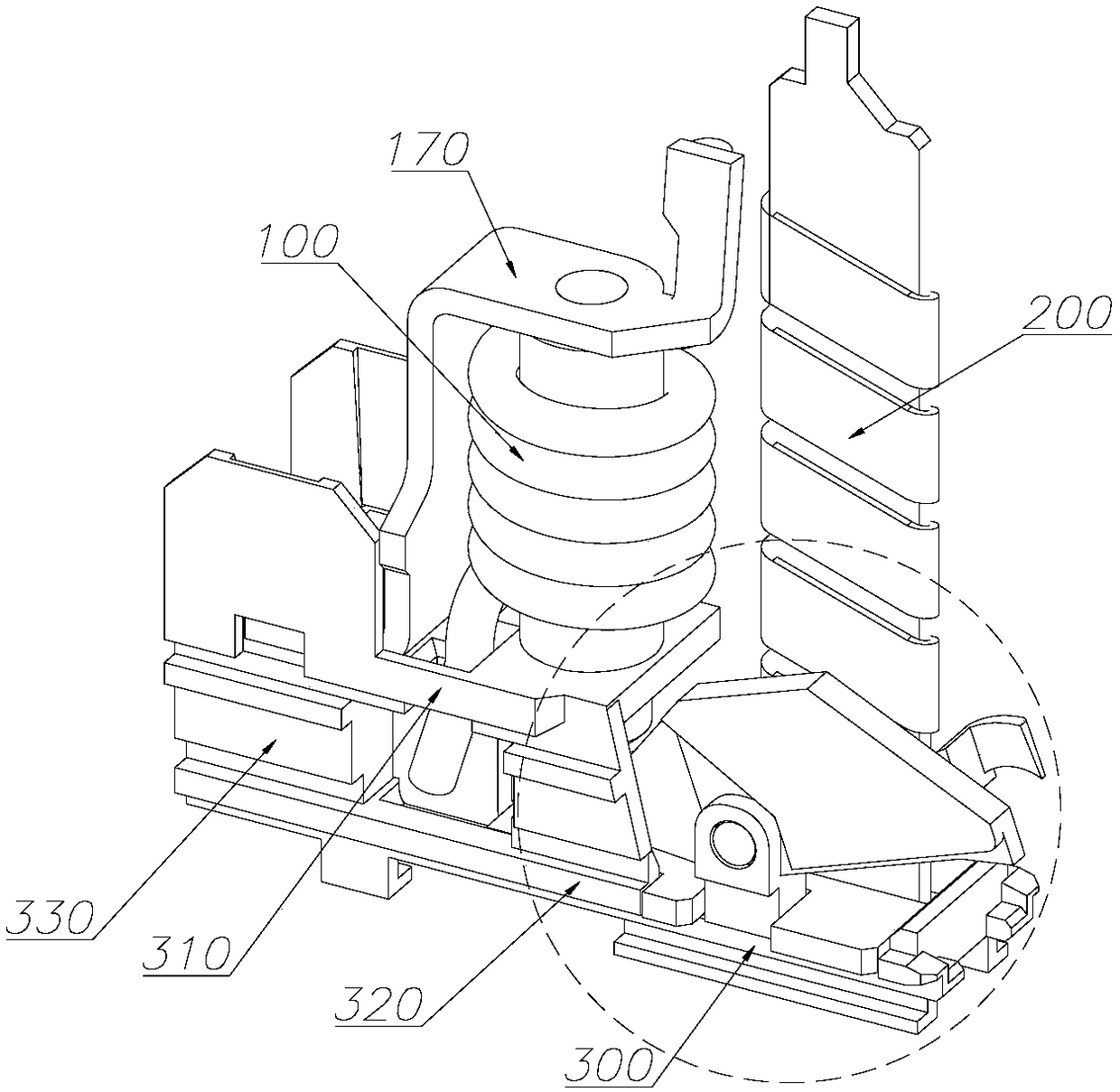

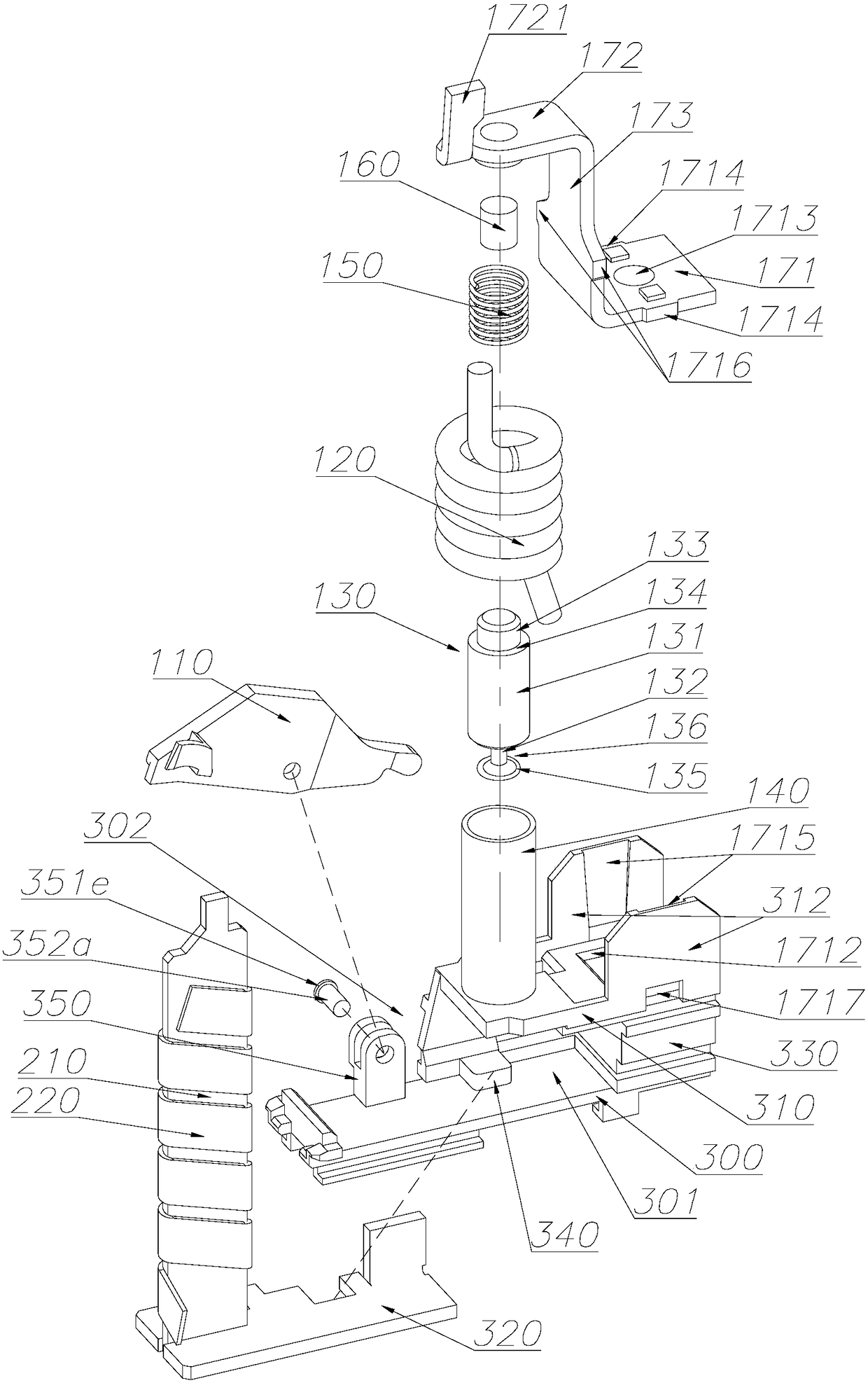

Small-sized direct-current circuit breaker with electric operation mechanism

InactiveCN110504142AMeet the functional needs of remote switching controlDimensions unchangedSwitching device condition indicationProtective switch operating/release mechanismsElectricityElectrical conductor

The invention discloses a small-sized direct-current circuit breaker with an electric operation mechanism. The small-sized direct-current circuit breaker comprises a first insulation shell and a second insulation shell which are arranged in parallel; a handle, at least one of overload and short circuit protection devices, an operation mechanism, a first tripping rod, a moving contact, a static contact, an arc extinguishing chamber, a wiring terminal and a conductor are arranged in the first insulation shell; the electric operation mechanism, a driving disc and a current collector are arrangedin the second insulation shell; and one end of the conductor is connected with one end of the overload protection device or the short circuit protection device, and the other end of the conductor sequentially penetrates through the hole centers of the first insulation shell, the second insulation shell and the current collector and then is connected with the wiring terminal. The small-sized direct-current circuit breaker can realize electricity utilization information collection and remote switching control on electric equipment.

Owner:TIANJIN JINGREN ELECTRIC APPLIANCE CO LTD

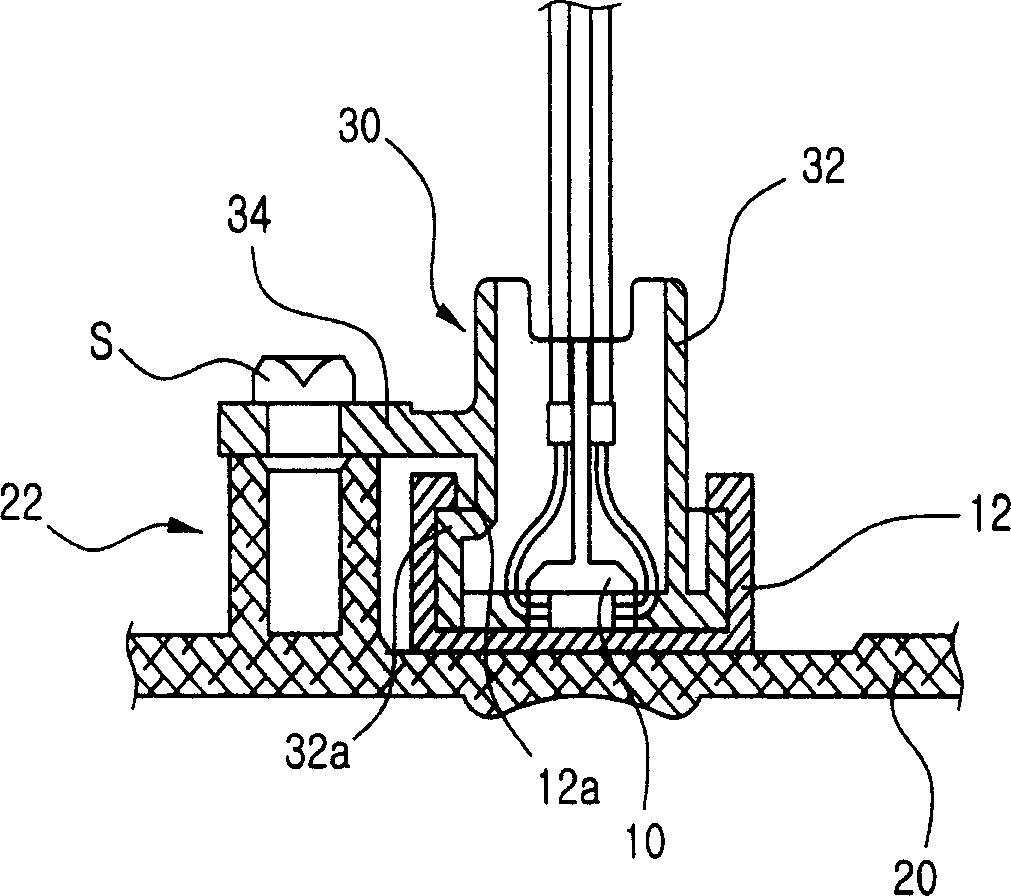

Set for installing thermal detector in pressure electric cooker

InactiveCN1626012AEliminate cumbersome proceduresAccurate temperature measurementThermometer detailsCooking-vessel lids/coversTemperature controlCooker

An installation structure for the temp measurer of electric pressure rice cooker is composed of a base plate of electrothermal wire, a temp measure arranged on said base plate, a supporter consisting of a cylindrical installing unit for holding said temp measurer and a fixing unit, and screws. Its advantages are high temp correctness and easy installing.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

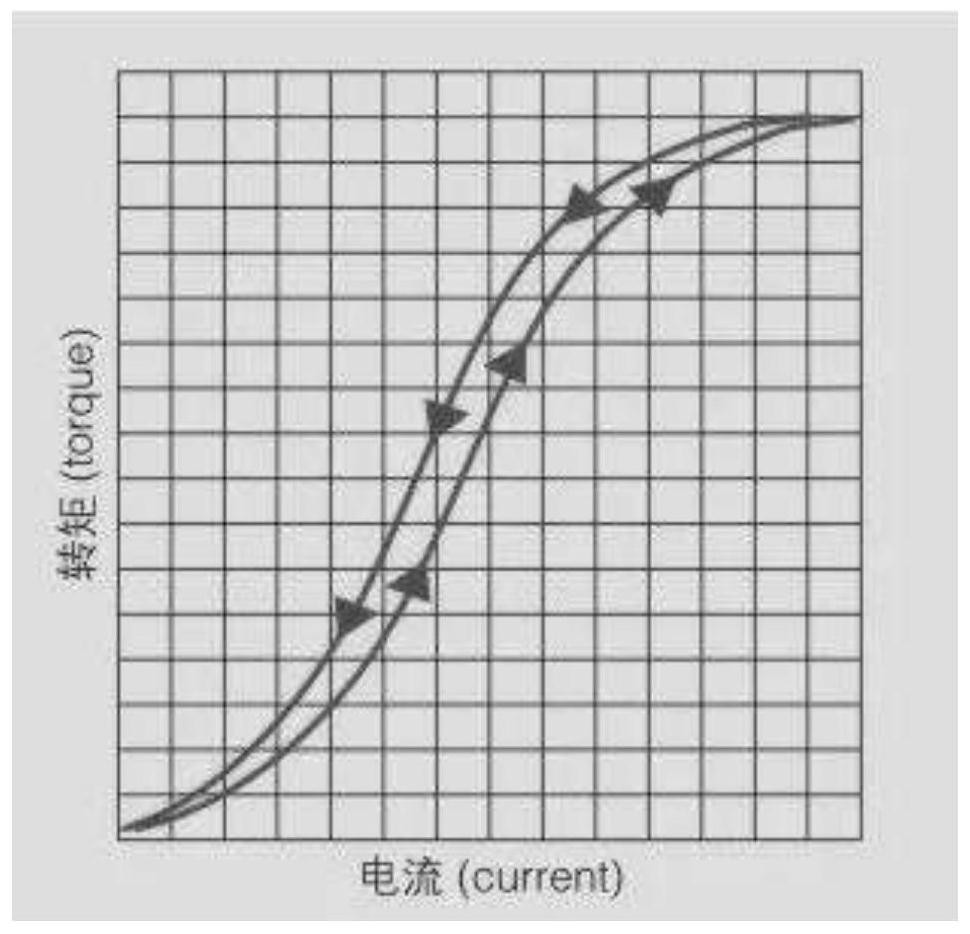

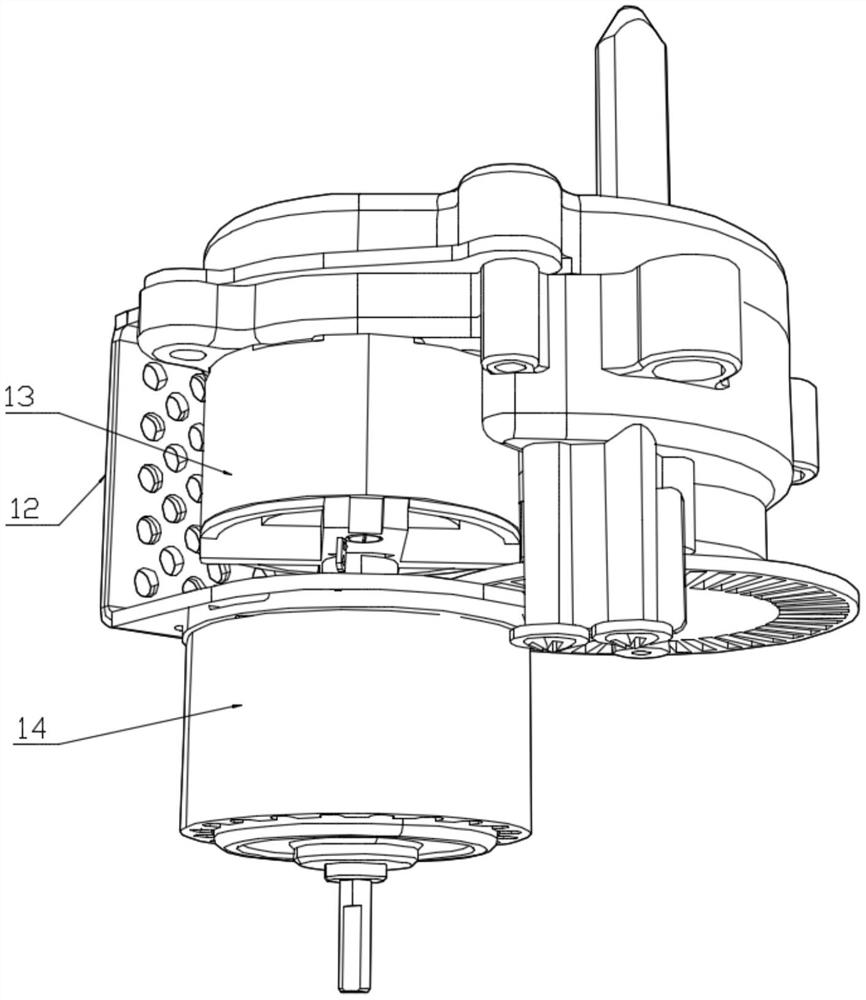

Miniature hysteresis brake suitable for brake system of intelligent rocking chair for children

PendingCN114157118ASmooth runningImprove stabilityAsynchronous induction clutches/brakesSupports/enclosures/casingsTorque transmissionElectric machinery

The invention relates to the technical field of intelligent rocking chair brakes for children, in particular to a miniature hysteresis brake suitable for an intelligent rocking chair brake system for children. The outer stator is fixedly arranged on the inner stator through a locking screw, and an annular gap is formed between the outer stator and the upper part of the inner stator; the rotor is fixedly installed on a brake shaft connected with a motor driving main shaft of the intelligent rocking chair for children in parallel, the rotor can rotate around the gap, the side wall of the inner stator is provided with an annular groove for a magnet exciting coil to wind, and the magnet exciting coil is wound on the inner stator. Non-contact torque transmission is adopted for braking, the maintenance cost and tedious procedures of a traditional friction plate are omitted, and the service life is long; smooth operation, good stability and large rotating speed range can be realized; based on the brake shaft, the torque transmitted by the brake shaft can be basically kept unchanged and is not affected by the sliding rotation speed of a motor of the intelligent rocking chair for children.

Owner:江西康雅医疗用品有限公司

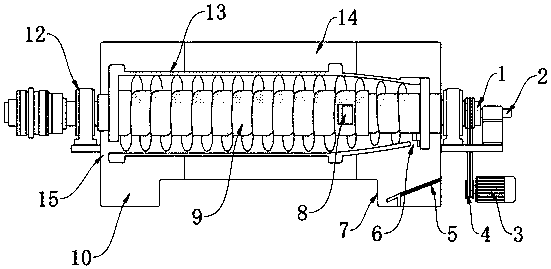

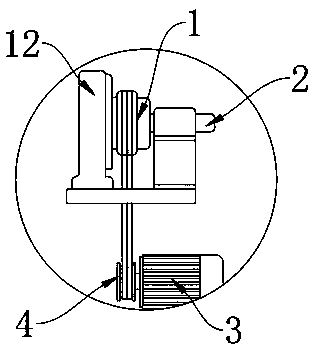

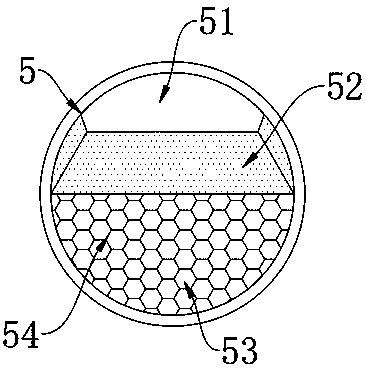

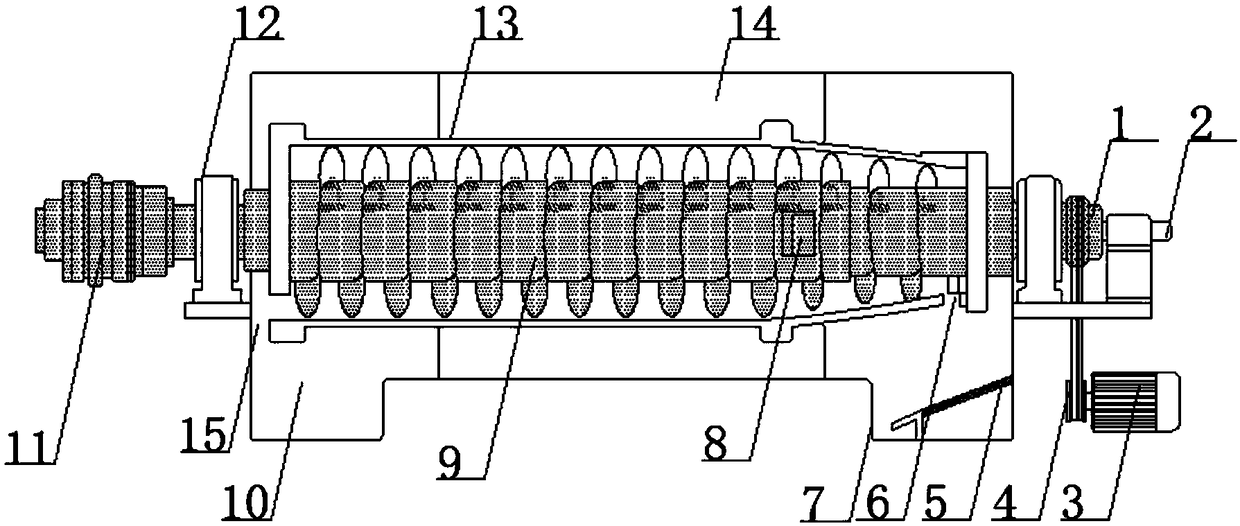

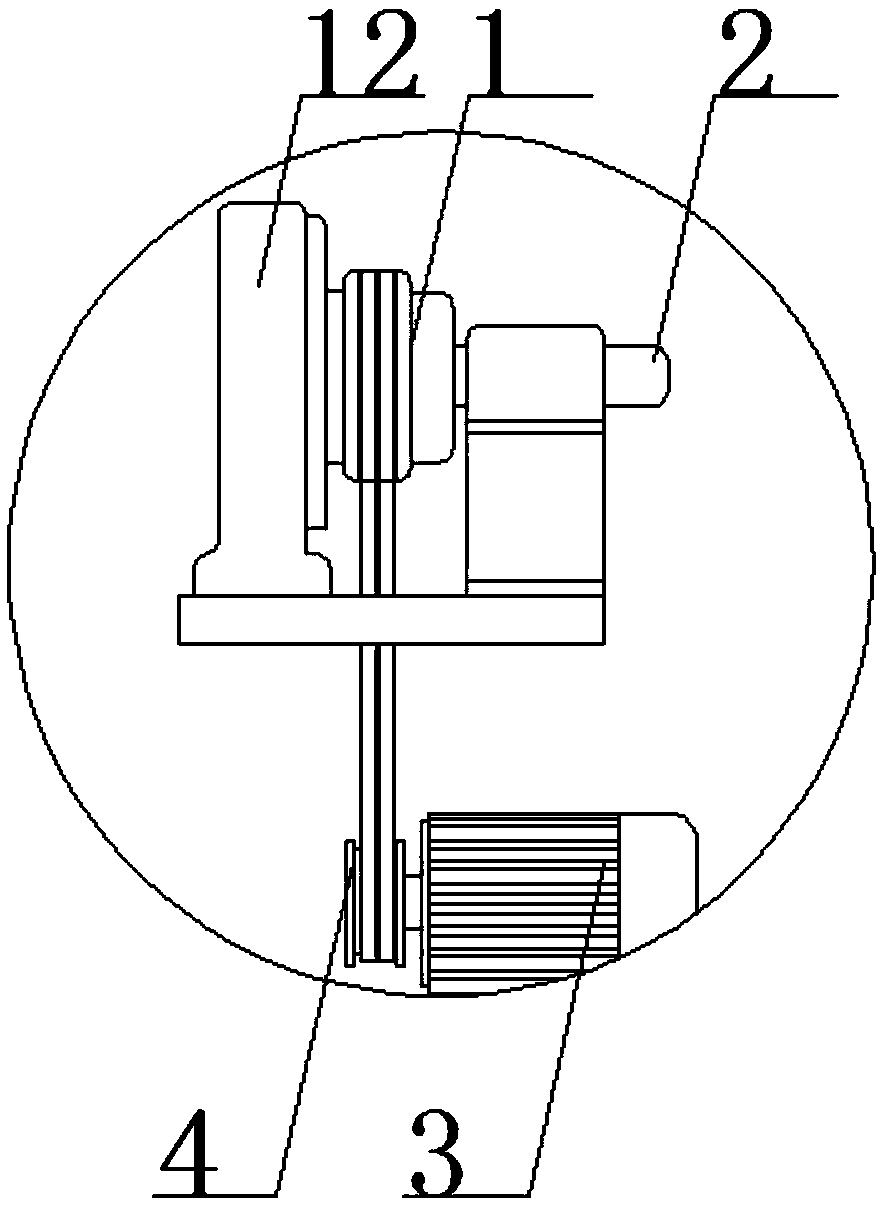

Horizontal screw separating machine

InactiveCN109453907ARealize screeningEliminate cumbersome proceduresCentrifugesEngineeringMechanical engineering

The invention discloses a horizontal screw separating machine. The horizontal screw separating machine comprises a shell cover and a barrate. The barrate is arranged in the shell cover. The circumferential edges of the barrate are movably connected into the shell cover by moving wheels. The barrate is internally provided with a screw pusher. The screw pusher is horizontally and transversely arranged in the barrate. Bearing seats are arranged at the left and right ends of the screw pusher. The bearing seats are arranged at the left and right ends of the shell cover. The left and right ends of the screw pusher are fixedly connected into the bearing seats by welding the outer surfaces of bearings. The bearing seats are connected with the left and right ends of the screw pusher in a sleeving mode. A material distributing device is arranged on the outer surface of the end, in the barrate, of the screw pusher. The material distributing device penetrates through the outer surface of one end of the screw pusher. In this way, material screening is achieved, and the problem of complex working procedures in subsequent screening is omitted. Convenience is achieved, and practicability is higher.

Owner:饶银娥

Integral jacking method for steel roof frame and concrete column articulated factory house cover

InactiveCN101476397BSave the heightening processEasy to installBuilding repairsSteel frameSupport point

The invention discloses a method for integrally jacking a factory building roof formed by hinging a steel roof truss and concrete columns. The method comprises the following steps: using the concrete columns of the factory building as jacking supporting members, and using corbels welded on the jacking supporting members as jacking supporting points; making use of a jacking device and a force transmission beam assembly which are placed on the corbels as a force application mechanism and a force transmission mechanism respectively so that the jacking force is transferred to a jacking member connected with the force transmission beam assembly; then jacking the factory building roof through the jacking member until the factory building roof reaches the required height; and finally, fixedly connecting the superposed parts of the bottom of the jacking member and the concrete columns to finish the jacking process. The jacking method has the advantages of simple construction process, short construction period, good safety, small investment, and the like.

Owner:五矿二十三冶建设集团有限公司

Method and system for recycling by-product hydrogen chloride in the chlorination production process of fatty acid or fatty acid chloride

ActiveCN105480948BEliminate cumbersome proceduresSimple process routeChlorine/hydrogen-chloride purificationOrganic compound preparationCatalytic oxidationOxygen

Owner:NANTONG TIANSHI CHEM

Cosmetic containing traditional Chinese medicine components and preparation technology thereof

ActiveCN105902481ANon-irritatingImprove securityCosmetic preparationsToilet preparationsWheat germCornus officinalis

The invention discloses a cosmetic containing traditional Chinese medicine components. The cosmetic is prepared from, by weight, 2-10 parts of lavender extracts, 12-25 parts of castor oil, 3-6 parts of radix bupleuri, 8-18 parts of cornus officinalis, 1-5 parts of roses, 2-8 parts of aloe juice, 2-8 parts of honey, 3-12 parts of chinese rice wine, 1-4 parts of yeast extracts, 2-4 parts of wheat germ, 4-8 parts of glycerinum, 2-4 parts of stearic acid, 2-6 parts of honeysuckle, 2-5 parts of radix pseudostellariae, 2-8 parts of lily and 2-4 parts of gingkoes. The invention further discloses a preparation technology of the cosmetic. Natural raw materials are adopted in the prepared cosmetic, the cosmetic has no irritation on skin, is high in safety, simple in preparation method and low in production cost, has the whitening and moistening effects and is resistant to the sun, and the complex procedures for smearing various cosmetics are omitted. Chinese herbal medicine such as radix bupleuri, cornus officinalis, roses, honeysuckle, radix pseudostellariae, lily and gingkoes are adopted, so that skin is finer, smoother, tender, white and elastic.

Owner:佛山市奥姿美生物科技有限公司

Lotus seed cake with lactation promoting function and preparation method thereof

InactiveCN105533591AHas the function of promoting lactationEliminate cumbersome proceduresFood scienceSalvia miltiorrhizaMiddle medulla

The invention relates to a lotus seed cake with a lactation promoting function and a preparation method thereof. The lotus seed cake is prepared from lotus seeds, salvia miltiorrhiza, medulla tetrapanacis, pettitoes, white hyacinth beans, cowherb seeds and radix trichosanthis. The preparation method is characterized in that the raw materials are pulped, heated and moulded by pouring, then automatic demolding is performed after cooling, and the product is dried and packaged, and a tedious procedure of wrapping the product with wafer is omitted, so that the process is simple. The prepared lotus seed cake has the advantages of long shelf life, rich nutrients and efficacy of promoting lactation.

Owner:郑州莉迪亚医药科技有限公司

Thermomagnetic system structure

PendingCN109390192AAvoid breakingAvoid accuracyProtective switch operating/release mechanismsSystem structureElectrical and Electronics engineering

The invention discloses a thermomagnetic system structure, and the structure comprises a magnetic trip module and a thermal trip module. The magnetic trip module is disposed on a magnetic trip fixingplate, and the thermal trip fixing plate is disposed on a thermal trip fixing plate. The magnetic trip fixing plate and the thermal trip fixing plate are disposed on a tripping pad plate, and the thermal tripping fixing plate is located between the magnetic tripping fixing plate and the tripping pad plate. The tripping pad plate is connected with the magnetic tripping fixing plate through a support. The tripping pad plate, the magnetic trip fixing plate and the support form an operation space for fixing the thermal trip fixing plate through enclosing. A fixing mechanism for fixing the thermaltrip fixing plate is disposed at one side of the operation space, and the thermal trip fixing plate is pushed into the operation space from the other side to be fixed on the tripping pad plate by thefixing mechanism. The thermal trip fixing plate is pushed into the operation space from one side to be fixed on the tripping pad plate by the fixing mechanism, so the assembly efficiency is high, andthe magnetic trip fixing plate does not need to be disassembled for directly taking down the thermal trip fixing plate, thereby facilitating maintenance.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Horizontal spiral separation machine

InactiveCN109317415ARealize screeningEliminate cumbersome proceduresSievingScreeningAgricultural engineeringRotating drum

The invention discloses a horizontal spiral separation machine. The horizontal spiral separation machine comprises a shell cover and a rotating drum; the rotating drum is arranged in the shell cover;the peripheral edge of the rotating drum is movably connected into the shell cover through a movable wheel; a spiral pusher is arranged in the rotating drum, and is horizontally arranged in the rotating drum; bearing bases are arranged at the left and right ends of the spiral pusher, and are arranged at the left and right ends of the shell cover; the left and right ends of the spiral pusher are fixedly connected into the bearing bases through welding of the outer surfaces of bearings; the bearing sleeves sleeve the left and right ends of the spiral pusher; a separation device is arranged on the outer surface of the end, in the rotating drum, of the spiral pusher; the separation device penetrates through the outer surface of one end of the spiral pusher to realize the material screening; and through classified screening, the problem of complicated procedures caused by subsequent screening is saved, more convenience is achieved, and the practicability is higher.

Owner:夏想

Cosmetic containing traditional Chinese medicine components and preparation process of cosmetic

InactiveCN109350585ANon-irritatingImprove securityCosmetic preparationsToilet preparationsBiotechnologyGlycerol

The invention discloses a cosmetic containing traditional Chinese medicine components. The cosmetic is prepared from, by weight, 2-10 parts of a lavender extract, 12-25 parts of castor oil, 3-6 partsof radix bupleuri, 8-18 parts of fructus corni, 1-5 parts of rose flowers, 2-8 parts of aloe juice, 2-8 parts of honey, 3-12 parts of yellow rice wine, 1-4 parts of a yeast extract, 2-4 parts of wheatgerms, 4-8 parts of glycerin, 2-4 parts of stearic acid, 2-6 parts of honeysuckle flowers, 2-5 parts of radix pseudostellariae, 2-8 parts of lily flowers and 2-4 parts of ginkgo. The invention further discloses a preparation process of the cosmetic. The prepared cosmetic adopts the natural raw materials and is not irritating to the skin, high in safety, simple in preparation method and low in production cost; the prepared cosmetic has the whitening and moisturizing effects and can prevent sunshade, and the complex process of applying various cosmetics every day is omitted; the prepared cosmetic adopts the traditional Chinese medicine components such as radix bupleuri, fructus corni, the rose flowers, the honeysuckle flowers, radix pseudostellariae, the lily flowers and ginkgo, so that theskin is more delicate, smoother, tenderer and whiter and rich in elasticity.

Owner:HEFEI LONGZHIYUN PHARM TECH CO LTD

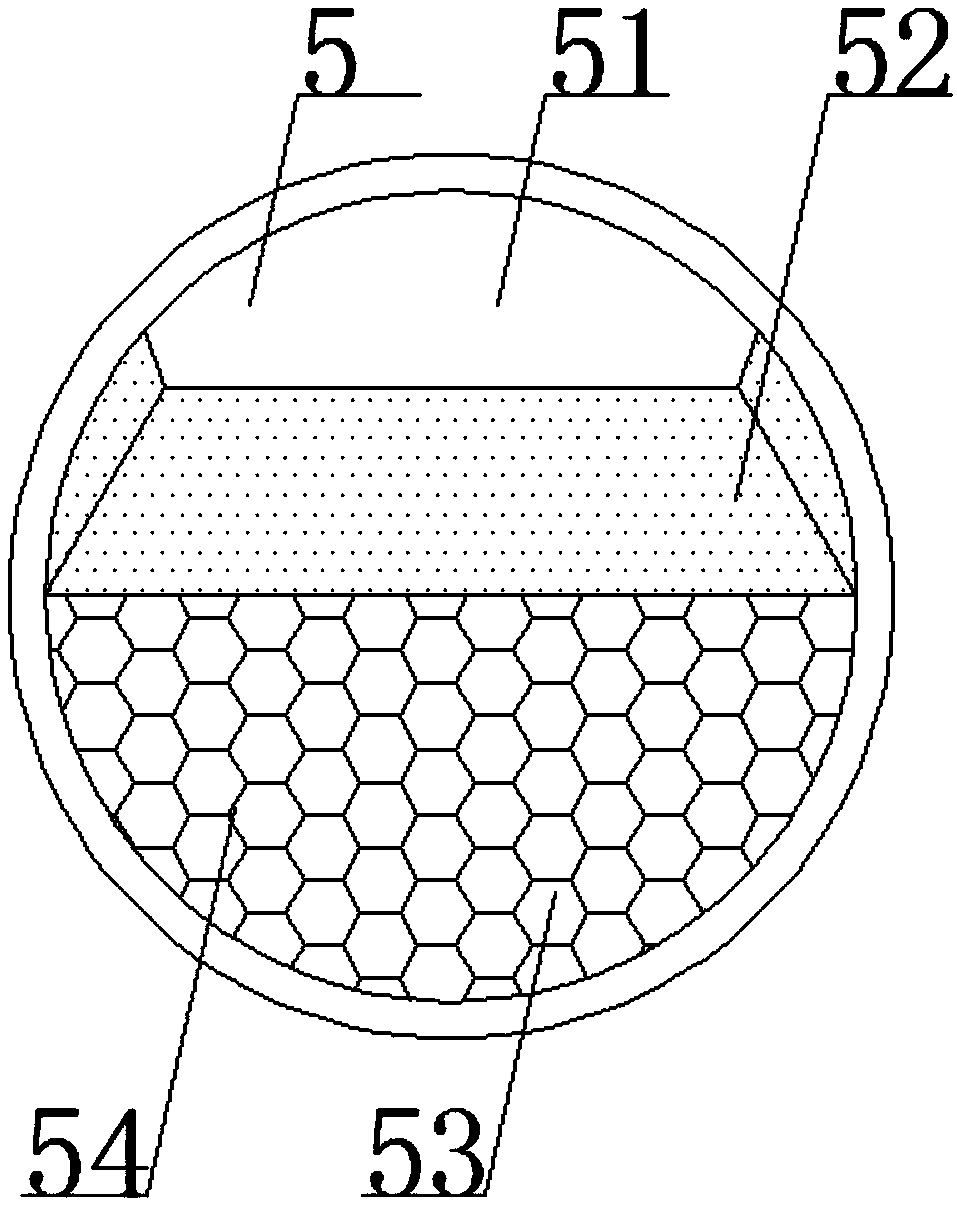

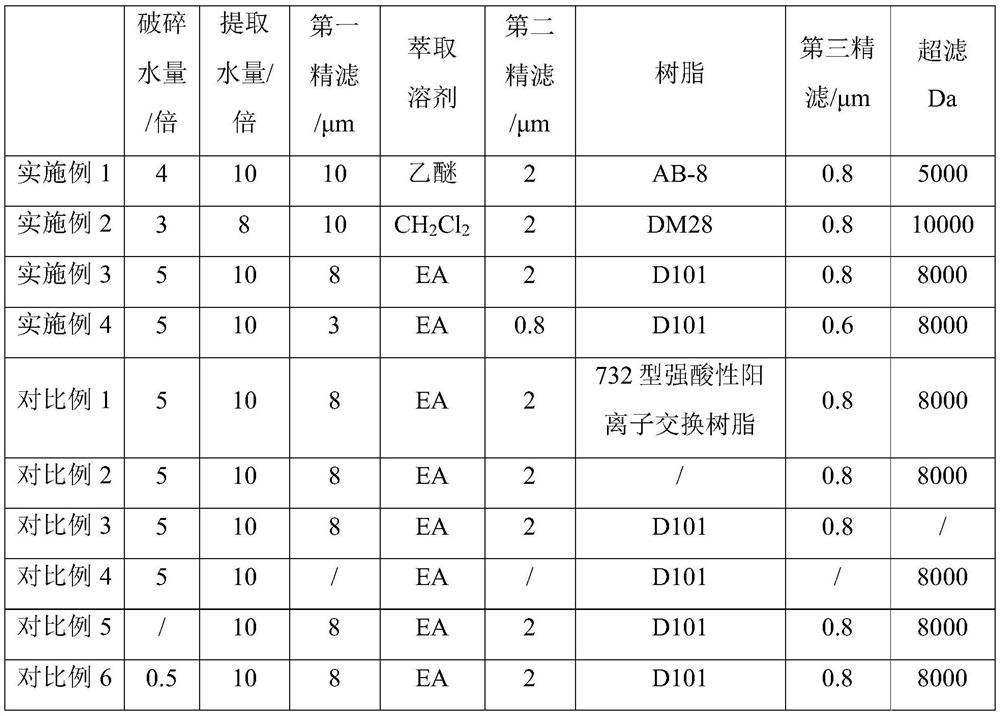

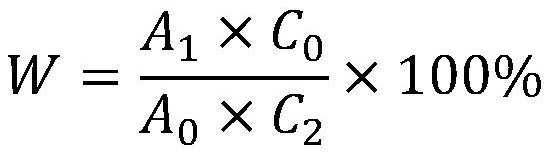

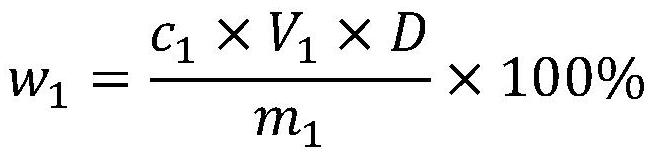

Areca-nut core extract as well as preparation method and application thereof

PendingCN113768123ANatural flavorIncrease profitNatural extract food ingredientsFood extractionArecolineSweet flavor

The invention relates to a preparation method of an areca-nut core extract. The preparation method comprises the following steps: mixing areca-nut cores with water, performing wet crushing, and then performing extraction to obtain an areca-nut extracting solution, wherein the weight ratio of the water to the areca-nut cores is (2-10): 1; performing first fine filtration on the areca-nut extracting solution, taking filtrate for extraction, and collecting a water-phase material; performing second fine filtration on the water-phase material, taking filtrate for adsorption by adopting macroporous resin, performing material pushing with water, and collecting column-passing liquid; and sequentially performing third fine filtration and ultrafiltration on the column-passing liquid, and collecting filtrate. The invention relates to the preparation method of the areca-nut core extract. The preparation method of the areca-nut core extract effectively removes arecoline, polyphenol, a sweetening agent, essence and spice in the areca-nut cores, so that the prepared areca-nut core extract has the flavor of areca-nuts, is free of astringent taste and sweet taste, natural in flavor and good in palatability.

Owner:HUNAN KOUWEIWANG GRP

Lotus seed cake for preventing fatty liver and preparation method thereof

InactiveCN105533697AEliminate cumbersome proceduresSimple processFood ingredient functionsSalvia miltiorrhizaFatty liver

The invention relates to a lotus seed cake for preventing fatty liver and a preparation method thereof. The lotus seed cake is prepared from lotus seeds, hawthorn fruits, Alisma plantago-aquatica, polygonum multiflorum, white hyacinth beans, Malva crispa seeds and salvia miltiorrhiza. The preparation method is characterized in that the raw materials are pulped, heated and moulded by pouring, then automatic demolding is performed after cooling, the product is dried and packaged, and a tedious procedure of wrapping the product with wafer is omitted, so that the process is simple. The prepared lotus seed cake has the advantages of long shelf life, rich nutrients and efficacy of preventing fatty liver.

Owner:郑州莉迪亚医药科技有限公司

A kind of invigorating spleen, invigorating qi and anti-cancer lotus seed cake and its preparation method

InactiveCN103876203BHas the effect of invigorating the spleen, invigorating qi and anti-cancerEliminate cumbersome proceduresAntineoplastic agentsFood ingredient functionsBiotechnologyNutrition

The invention relates to a lotus seed cake for invigorating spleen, invigorating qi and anti-cancer and a preparation method thereof. The present invention is characterized in that the raw materials are beaten and then heated and poured into shape, automatically released from the mold after cooling, and can be packaged after drying, which saves the cumbersome process of wrapping glutinous rice paper. The process is simple, the shelf life is long, and the nutrition is rich. The effect of cancer.

Owner:于海霞

A kind of cosmetic containing traditional Chinese medicine components and its preparation process

ActiveCN105902481BNon-irritatingImprove securityCosmetic preparationsToilet preparationsIrritationStearic acid

The invention discloses a cosmetic containing traditional Chinese medicine components. The cosmetic is prepared from, by weight, 2-10 parts of lavender extracts, 12-25 parts of castor oil, 3-6 parts of radix bupleuri, 8-18 parts of cornus officinalis, 1-5 parts of roses, 2-8 parts of aloe juice, 2-8 parts of honey, 3-12 parts of chinese rice wine, 1-4 parts of yeast extracts, 2-4 parts of wheat germ, 4-8 parts of glycerinum, 2-4 parts of stearic acid, 2-6 parts of honeysuckle, 2-5 parts of radix pseudostellariae, 2-8 parts of lily and 2-4 parts of gingkoes. The invention further discloses a preparation technology of the cosmetic. Natural raw materials are adopted in the prepared cosmetic, the cosmetic has no irritation on skin, is high in safety, simple in preparation method and low in production cost, has the whitening and moistening effects and is resistant to the sun, and the complex procedures for smearing various cosmetics are omitted. Chinese herbal medicine such as radix bupleuri, cornus officinalis, roses, honeysuckle, radix pseudostellariae, lily and gingkoes are adopted, so that skin is finer, smoother, tender, white and elastic.

Owner:佛山市奥姿美生物科技有限公司

Multipurpose natural cosmetic containing traditional Chinese medicine component and preparation method thereof

ActiveCN103393586BAvoid harmImprove securityCosmetic preparationsToilet preparationsVitamin CIrritation

The invention discloses a multipurpose natural cosmetic containing a traditional Chinese medicine component and a preparation method thereof and belongs to the technical field of cosmetic preparation. The multipurpose natural cosmetic containing the traditional Chinese medicine component is prepared from the following raw materials by weight percent: 10-20% of lanolin, 1-2 % of tea polyphenol, 1-5% of vitamin C, 1-5% of vitamin E, 5-10% of castor oil, 0.5-2% of papain, 1-8% of aloe juice, 0.2-1.2% of borneol, 1-4% of honey, 0.5-1.5% of citric acid, 8-15% traditional Chinese medicine component and the balance of deionized water. The multipurpose natural cosmetic adopts natural raw materials, the skin affinity is good, irritation is low, the safety is high, and the multipurpose natural cosmetic can be taken orally and externally applied, has the effects of whitening and moisturizing and is radiationproof and sunproof, so that a tedious process of smearing multiple cosmetics everyday is eliminated; besides, the preparation method of the multipurpose natural cosmetic is simple, and the production cost is low.

Owner:山东福瑞达生物股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com