Anti-seepage vacuum insulation outer wall facing tile

A technology for vacuum insulation and wall tiles, applied in covering/lining, architecture, building structure, etc., can solve the problem of single facade aesthetics, and achieve the effect of eliminating cumbersome processes, strengthening firmness, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

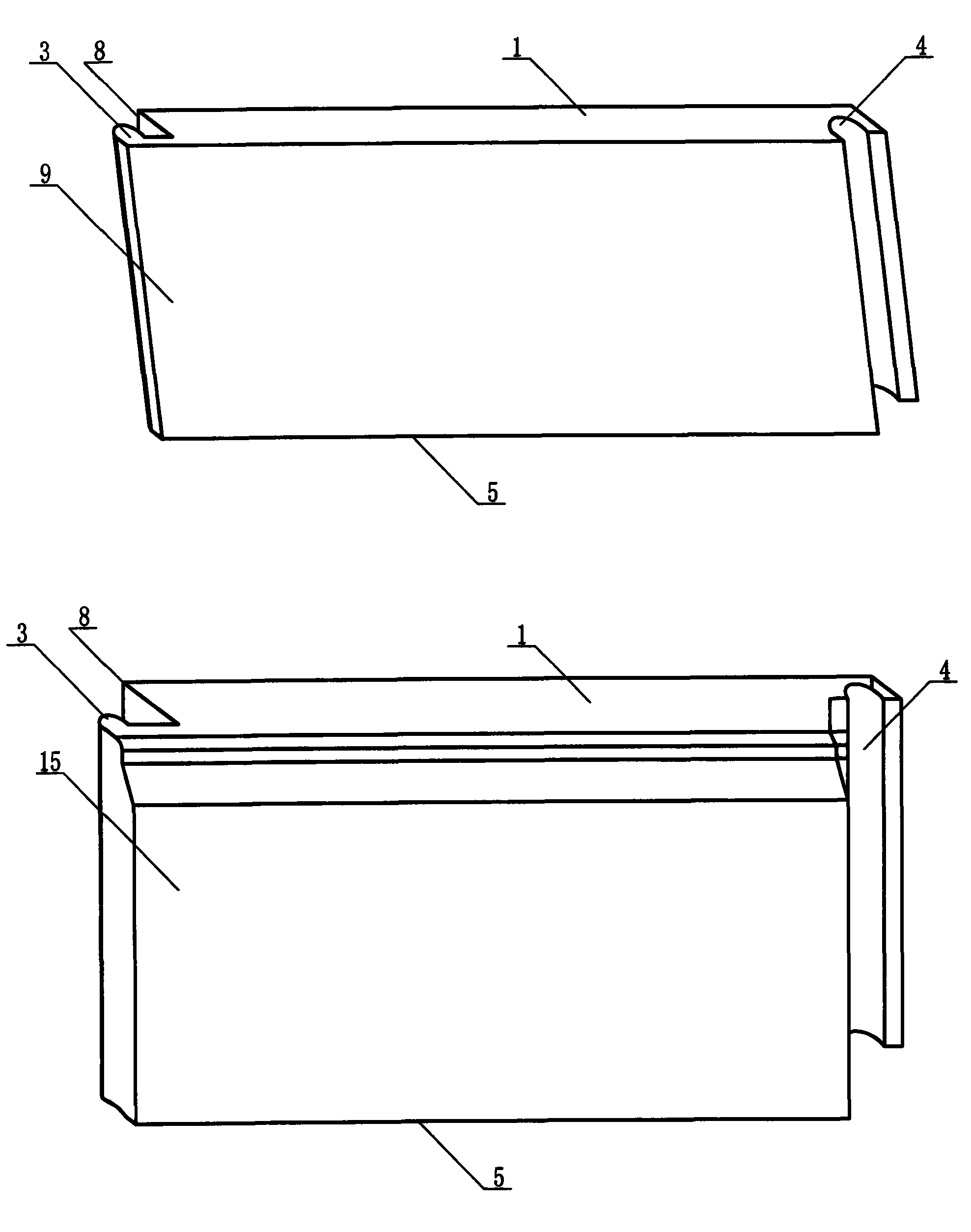

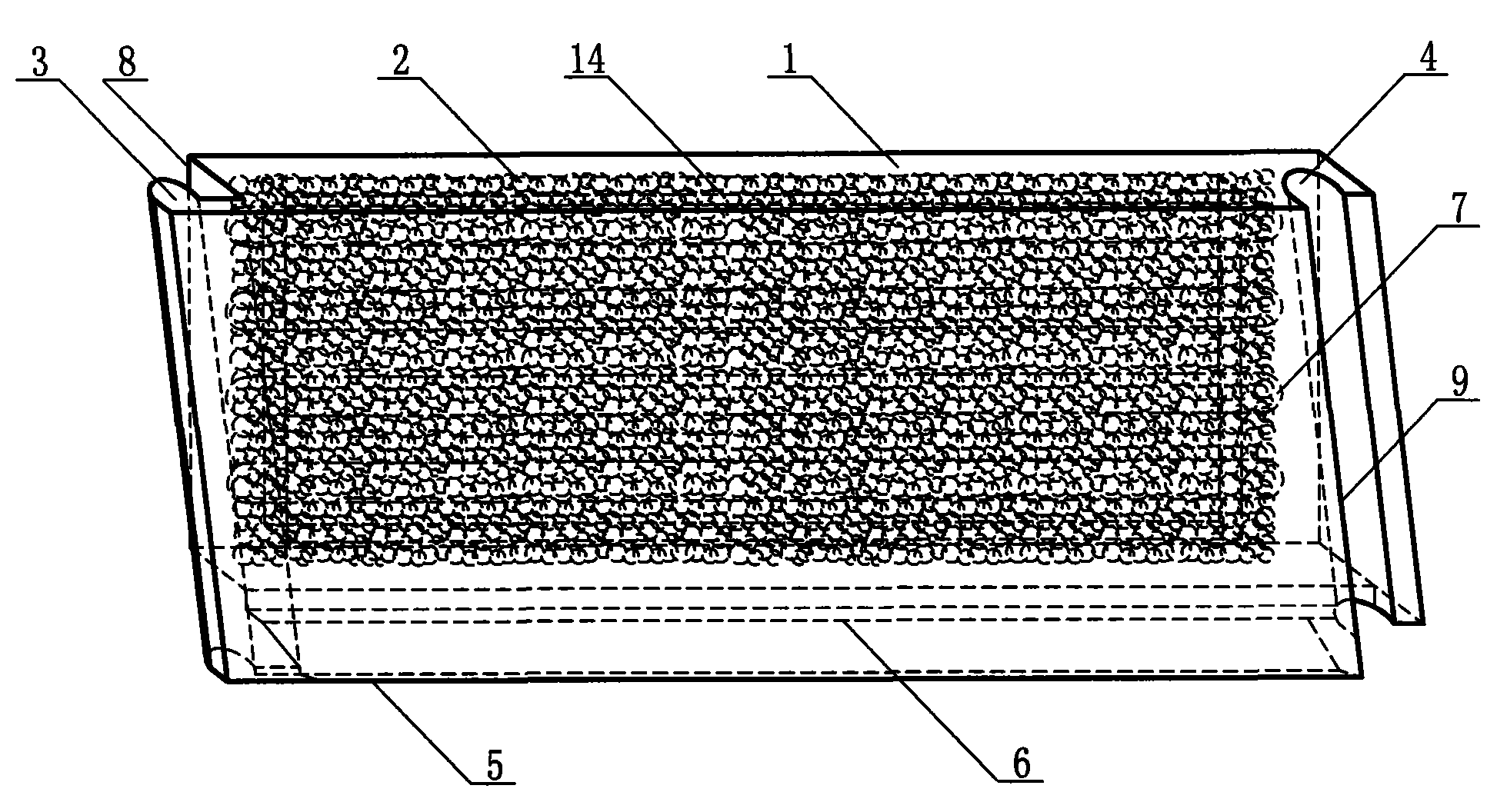

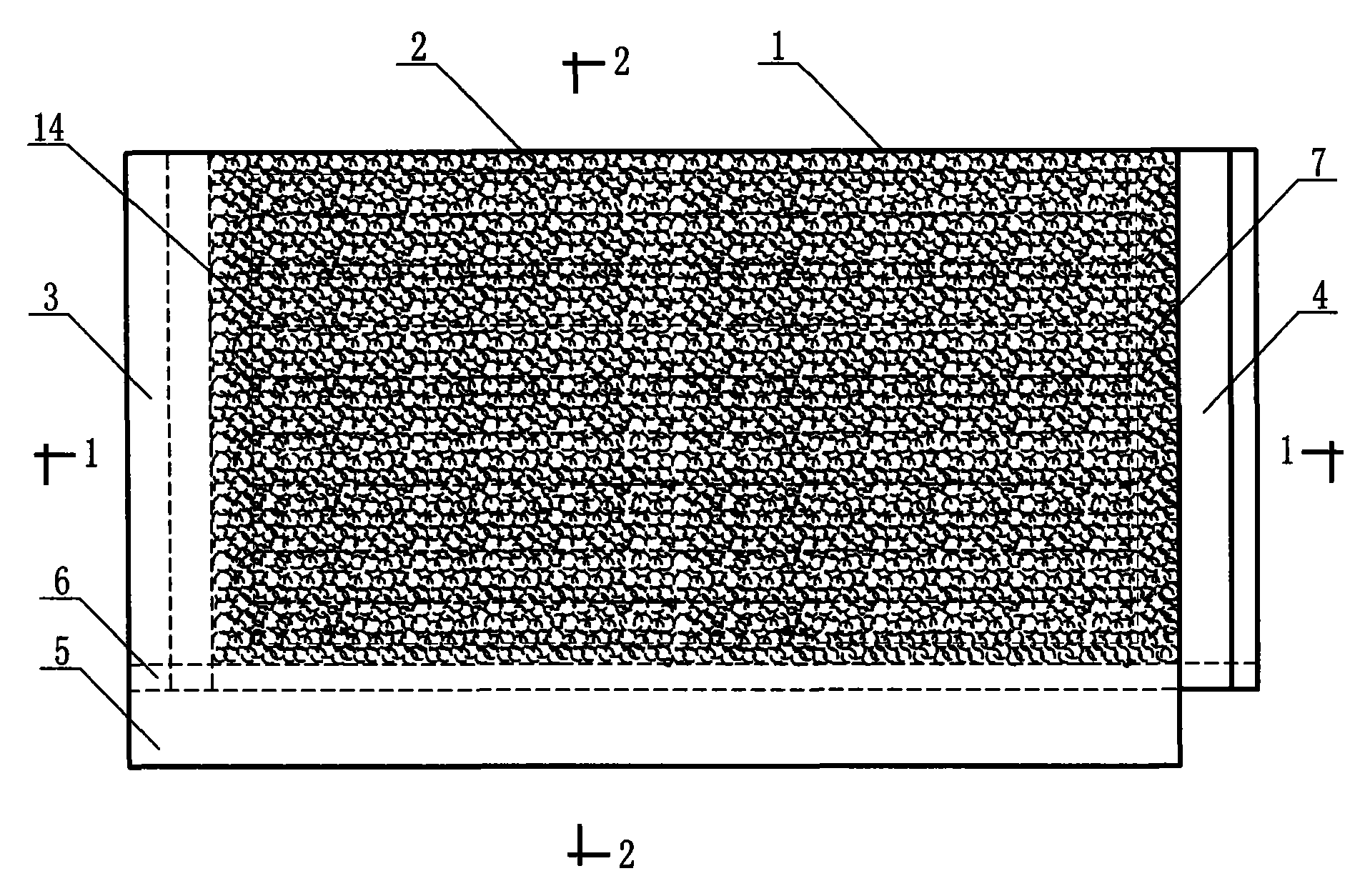

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 As shown, when the building 12 masonry is completed, 11 bottom ash mortar is applied, and the 13 integral anti-seepage vacuum insulation exterior wall brick control line is set on the plastered 11 bottom ash mortar, and the 13 integral anti-seepage vacuum insulation exterior wall tiles are started to be paved. For wall bricks, use a spatula to scrape 10 adhesive layer mortar (knife ash) on the back of 13 integral anti-seepage vacuum insulation outer wall brick 8 and the groove on the back of 7, stick it on the surface of 11 bottom ash mortar, press hard, and use The handle of the spatula is tapped lightly, so that the 13 integral anti-seepage vacuum insulation outer wall bricks are closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com