An unreinforced steel-UHPC composite bridge deck structure and a construction method thereof

A technology of combined bridge deck and steel bridge deck, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of reducing UHPC shrinkage performance, high labor cost and resource consumption, hindering the development of composite bridge decks, etc., to achieve bridge The overall bearing capacity and fatigue resistance of the surface are excellent, the construction labor cost is reduced, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

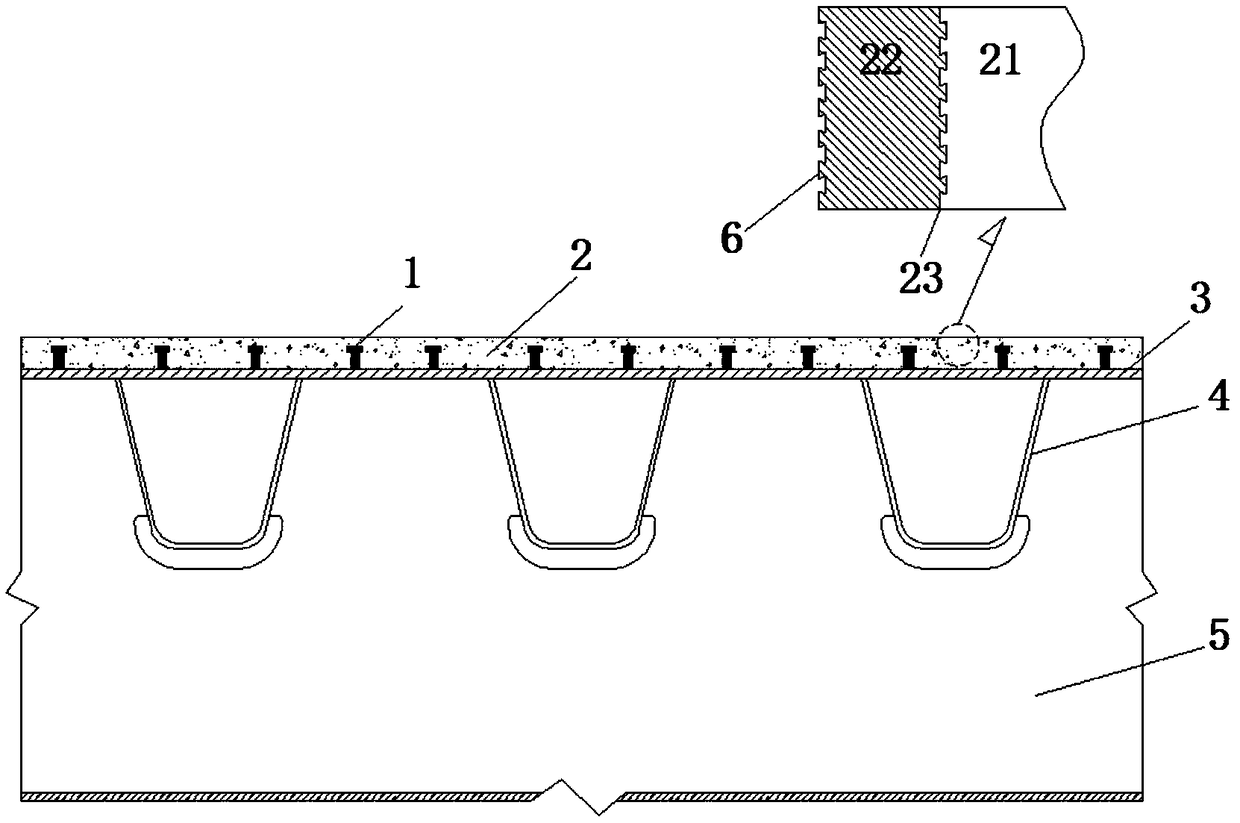

[0049] refer to Figure 1~5 : A kind of unreinforced steel-UHPC composite deck structure of the present embodiment, the steel-UHPC composite bridge deck structure is made up of UHPC bridge deck 2, orthotropic steel bridge deck 3 and connecting stud 1, and UHPC The main part of the bridge deck 2 is not equipped with stress reinforcement and structural reinforcement; the steel bridge deck 3 is provided with connecting pegs 1 embedded in the UHPC bridge deck 2, and the connecting pegs 1 are evenly distributed on the steel bridge deck 3 , the distance between adjacent pegs is 15cm-55cm.

[0050] The UHPC bridge deck 2 is formed by segmental cast-in-place.

[0051] The adjacent UHPC bridge deck 2 units of UHPC bridge deck 2 segmented cast-in-place are connected by key-tooth joints 6 or flat joints with dense reinforcement.

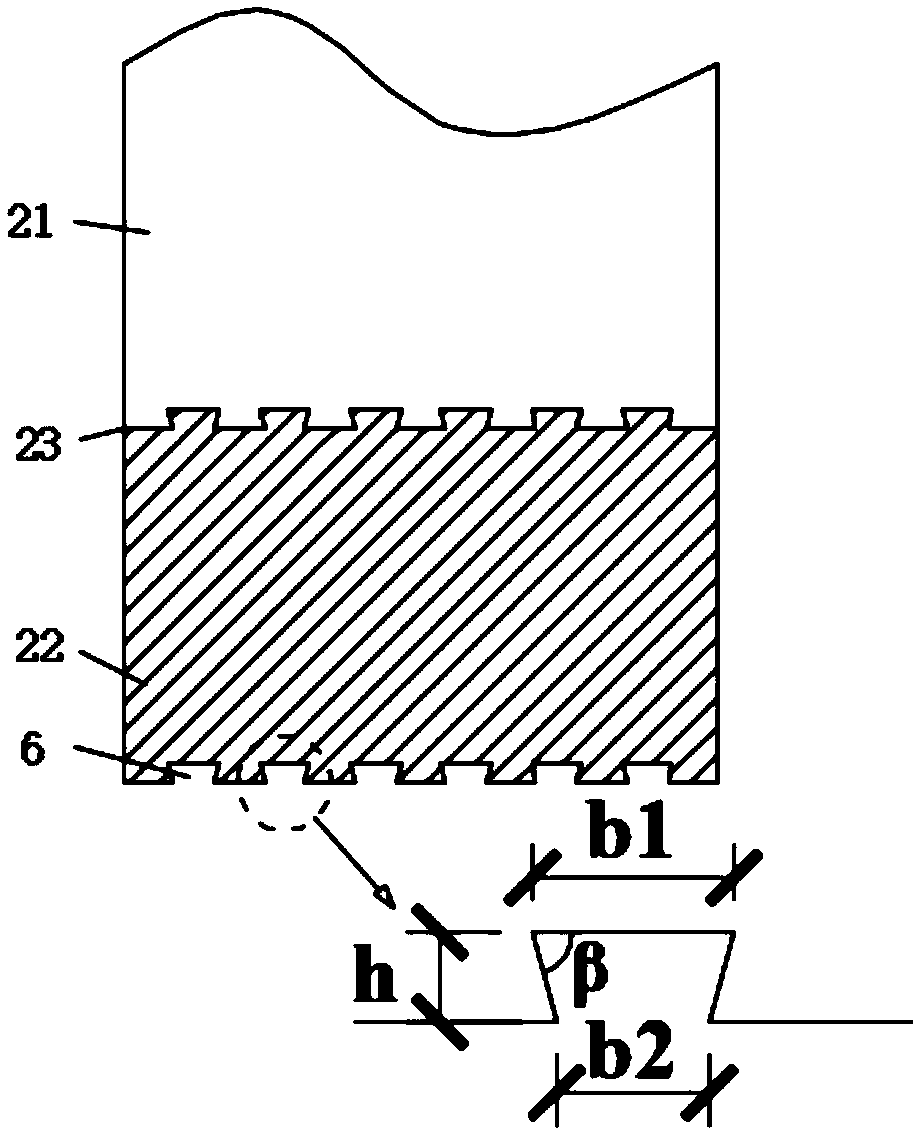

[0052] The key tooth bite joint 6 is an inverted trapezoidal joint. The design parameters of inverted trapezoidal joints generally need to meet b 2 ≥10cm; ...

Embodiment 2

[0077] refer to figure 1 with 7 ~9, an unreinforced steel-UHPC composite deck structure of this embodiment, compared with embodiment 1, has the following differences:

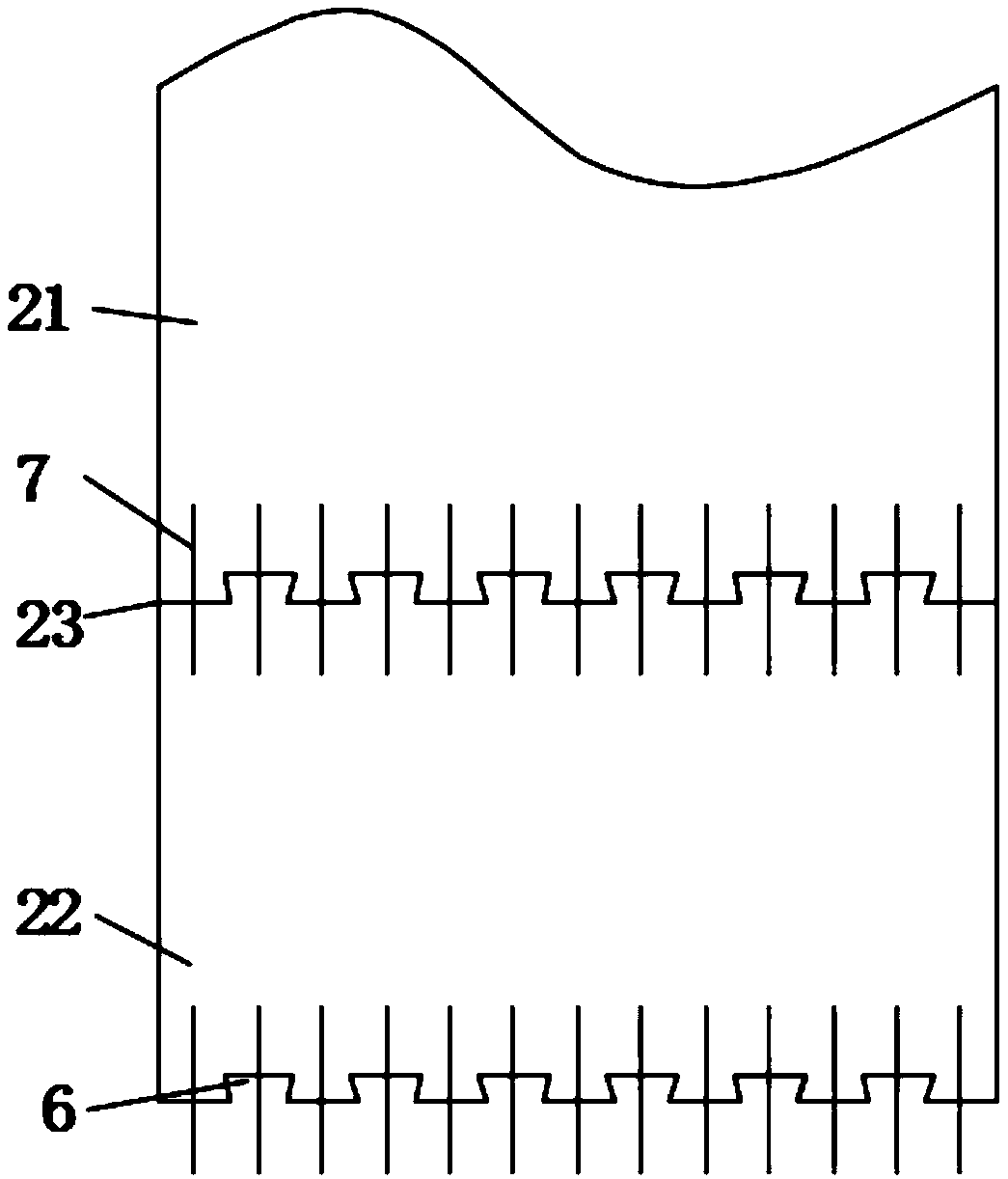

[0078] The key tooth bite joint 6 is a "T" joint, and the design parameters of the "T" joint generally need to meet h≥1.5×b 2 ;5cm≤b 2 and other requirements, the symbols are shown in the appendix Figure 7 ; By improving the structure of the key-tooth joint 6, the mutual bite force between the key-tooth joints 6 of adjacent UHPC bridge decks 2 is improved, thereby reducing or even eliminating the artificial fracture of the UHPC bridge deck 2 on its joints. weakening of tensile strength.

[0079] The metal corrugated sleeve 8 is a closed sleeve.

[0080] The metal corrugated sleeve 8 is provided with a vertical rib 13 for limiting the joint threaded steel bar 7, the vertical rib 13 is uniformly distributed along the inner wall of the metal corrugated sleeve 8, and the vertical rib 13 is arranged on the ...

Embodiment 3

[0084] refer to Figure 10: A kind of unreinforced steel-UHPC composite deck structure of the present embodiment, the steel-UHPC composite bridge deck structure is made up of UHPC bridge deck 2, orthotropic steel bridge deck 3 and connecting stud 1, and UHPC The main part of the bridge deck 2 is not equipped with stress reinforcement and structural reinforcement; the steel bridge deck 3 is provided with connecting pegs 1 embedded in the UHPC bridge deck 2, and the connecting pegs 1 are evenly distributed on the steel bridge deck 3 , the distance between adjacent pegs is 15cm-55cm.

[0085] The UHPC bridge deck 2 is formed by integral casting.

[0086] A construction method for integral cast-in-place construction of an unreinforced steel-UHPC composite deck structure, comprising the following steps:

[0087] 1) welding the steel connecting studs 1 to the steel bridge deck 3 evenly and equidistantly, and extending the connecting studs 1 upwards into the UHPC bridge deck 2 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com