Thermomagnetic system structure

A system structure, thermal magnetic technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problem of inaccurate positioning of thermal tripping fixed plate, magnetic tripping fixed plate and tripping backing plate, unstable connection strength and precision, and connection The strength does not meet the requirements and other problems, to achieve the effect of omitting cumbersome procedures, reliable connection, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

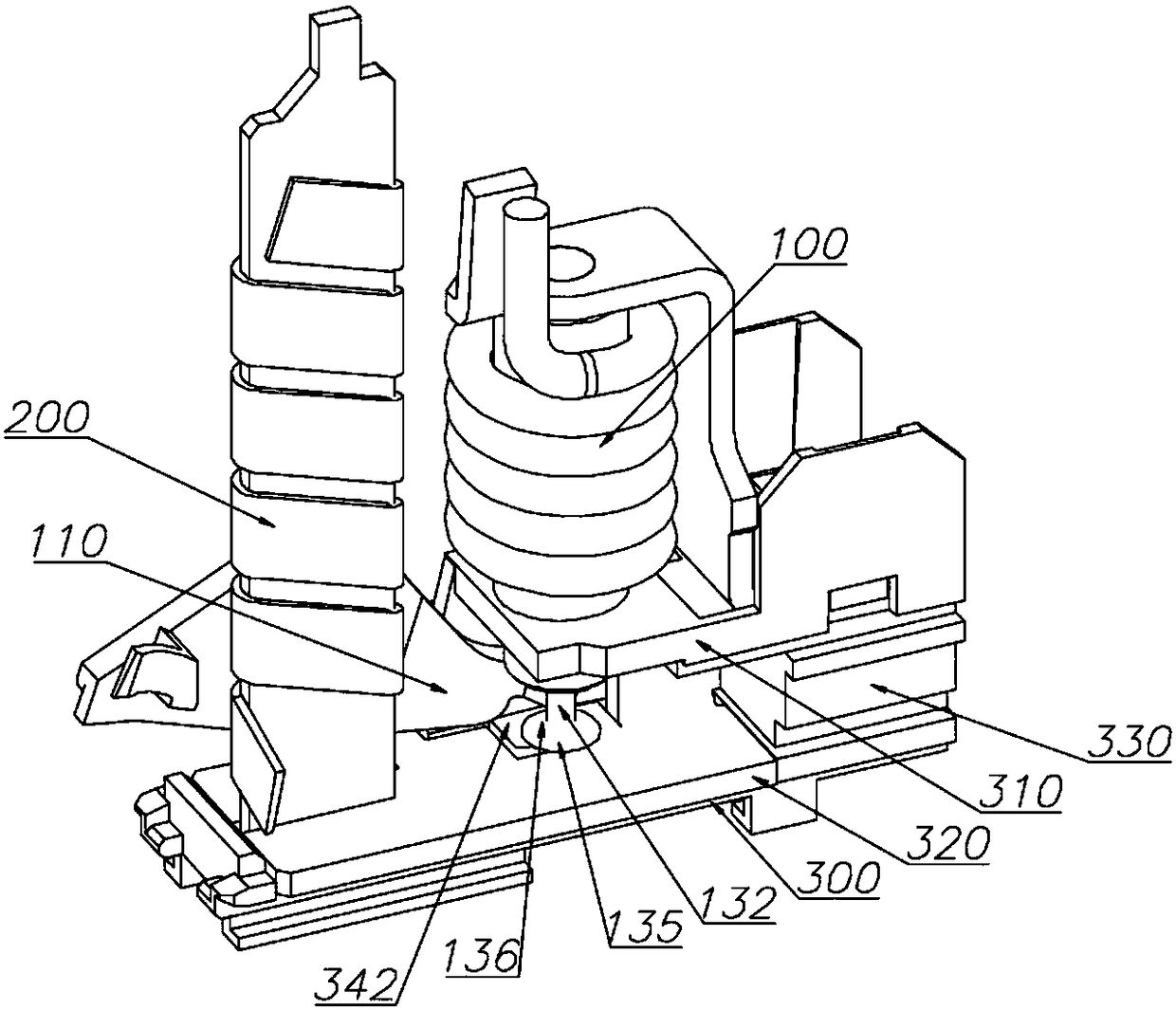

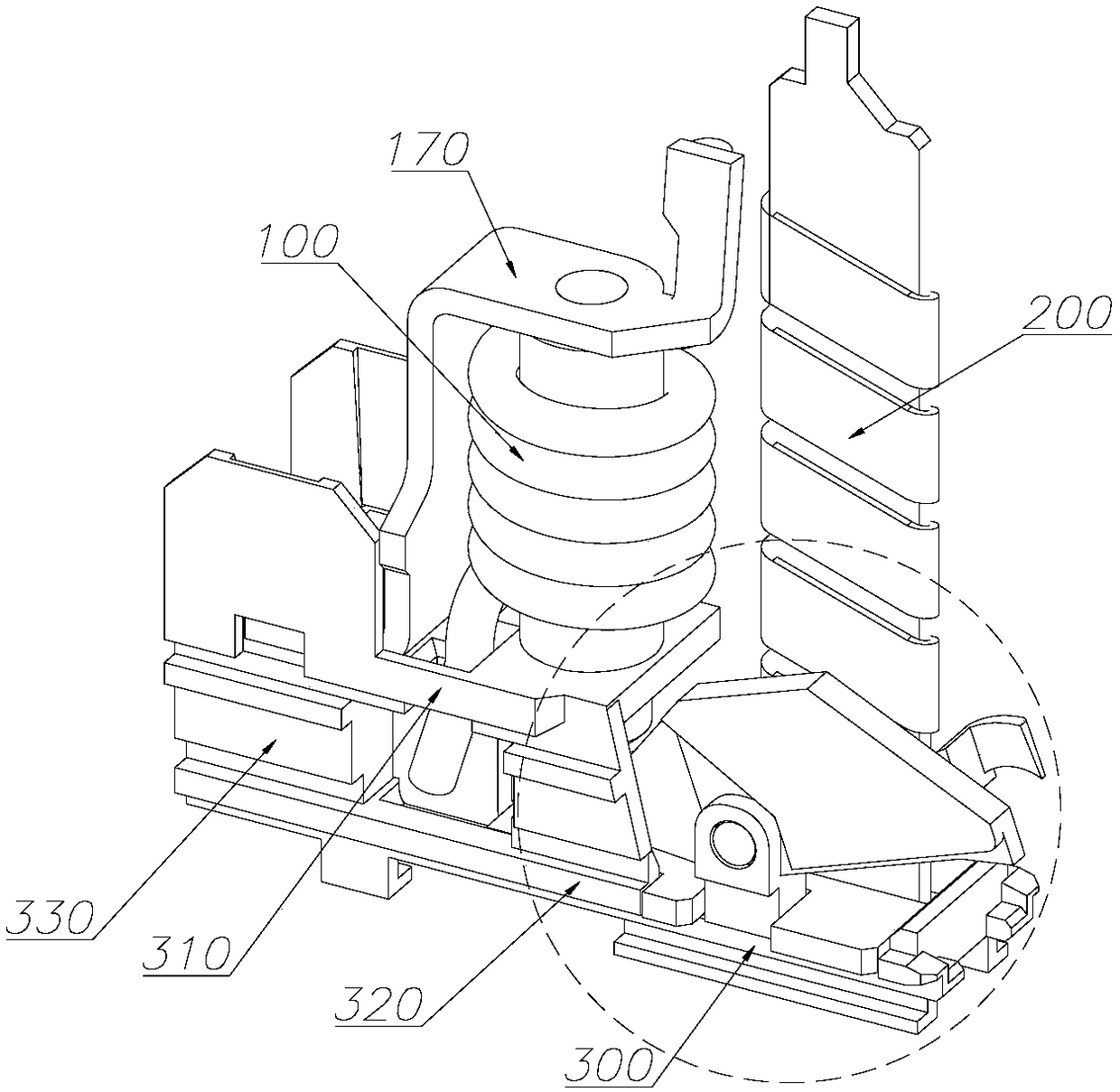

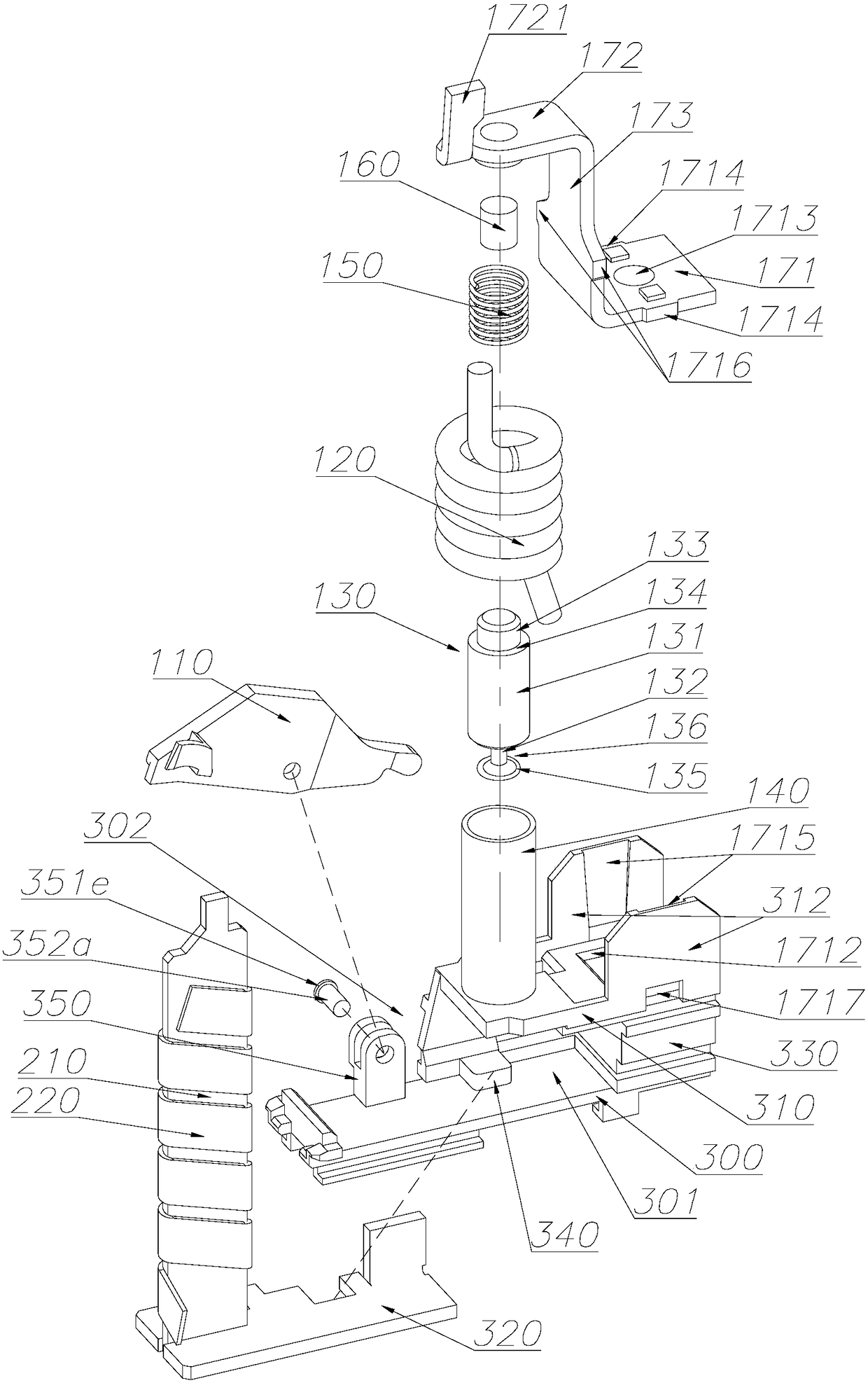

[0034] The following is attached Figures 1 to 9 The given examples further illustrate the specific implementation of the thermomagnetic system structure of the present invention. The structure of the thermomagnetic system of the present invention is not limited to the description of the following embodiments.

[0035] Such as Figure 1-3 In the shown embodiment, the thermal-magnetic system structure of the present invention includes a magnetic trip module 100 and a thermal trip module 200, the magnetic trip module 100 is arranged on the magnetic trip fixing plate 310, and the thermal trip fixing plate 320 is arranged on the On the thermal trip fixing plate 320, the magnetic trip fixing plate 310 and the thermal trip fixing plate 320 are arranged on the trip backing plate 300, and the thermal trip fixing plate 320 is located on the magnetic trip fixing plate 310 and the trip backing plate 300 between;

[0036] The tripping backing plate 300 is connected to the magnetic trip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com