Fully automatic production line for special-shaped paperboard books

A production line, fully automatic technology, applied in the direction of conveyor objects, sending objects, stacking receiving devices, etc., can solve the problems of large number of people in production, input of labor force, affecting production efficiency, etc., to avoid cumbersome procedures, reduce the number of groups, The effect of reducing the initial investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions required by the present invention will now be described in detail in conjunction with the accompanying drawings and specific embodiments.

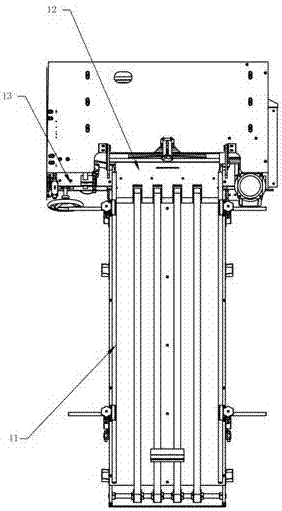

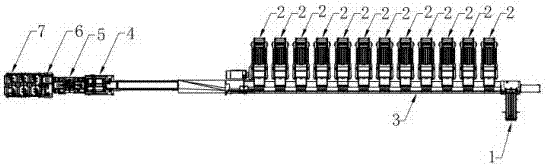

[0034] See attached figure 1 As shown, a full-automatic production line for special-shaped cardboard books in this embodiment includes a book closing device 1 arranged in sequence, multiple sets of local gluing devices 2, and a counter-mounting device arranged between the ends of the local gluing devices 2. Device 3, U-turn device 4, stacking storage device 5, left and right flow diversion mechanism 6, six-head flat pressure cylinder book pressing device 7.

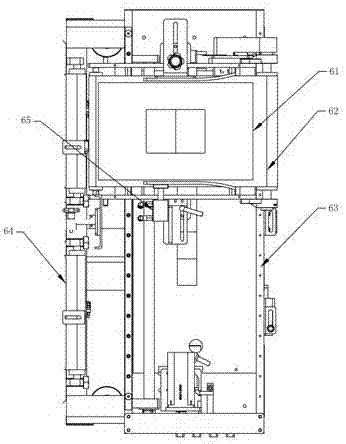

[0035] see figure 2 and image 3 As shown, a mounting device 3 is provided between the book closing device 1 and the ends of the partial gluing devices 2, and the mounting device 3 includes a mounting device 3 for pushing the flag 31 and driving the pushing flag 31 to move in the horizontal direction Push the flag 31 guide rails, the book closing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com