Integral jacking method for steel roof frame and concrete column articulated factory house cover

An integral jacking, steel roof truss technology, applied in building maintenance, construction, building construction, etc., can solve problems such as inconvenient jacking, material and labor costs, and save investment, eliminate cumbersome procedures, and shorten construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

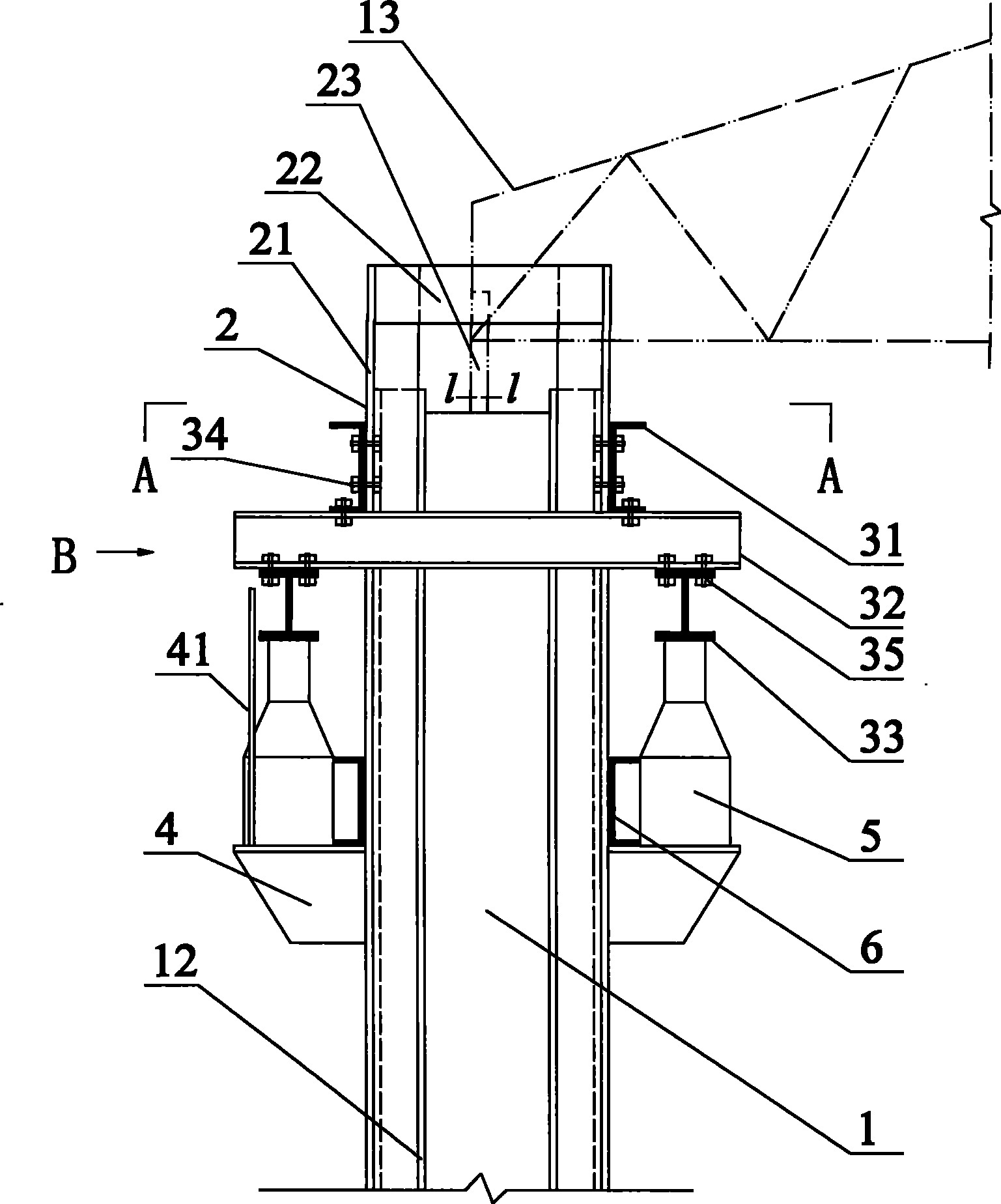

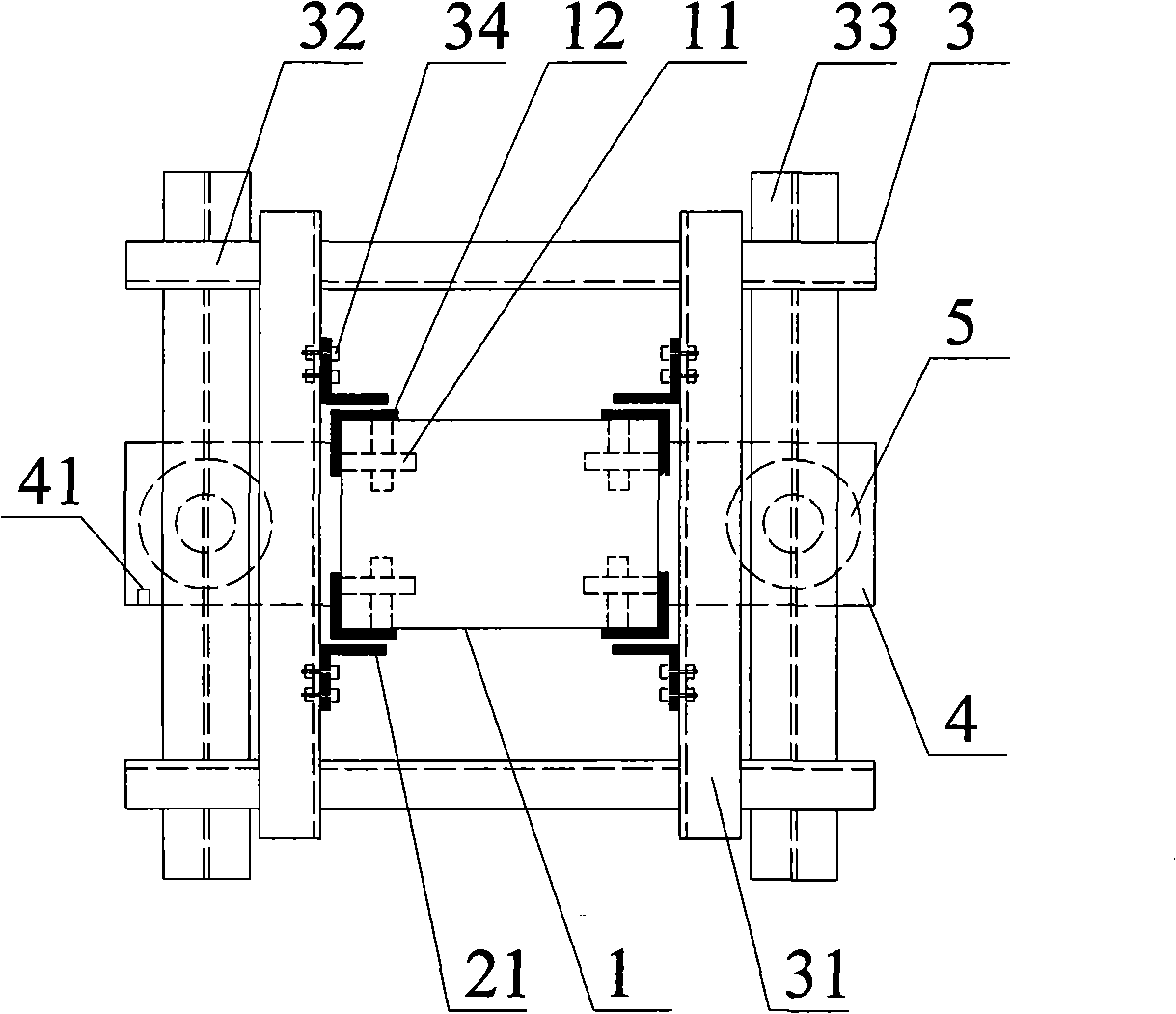

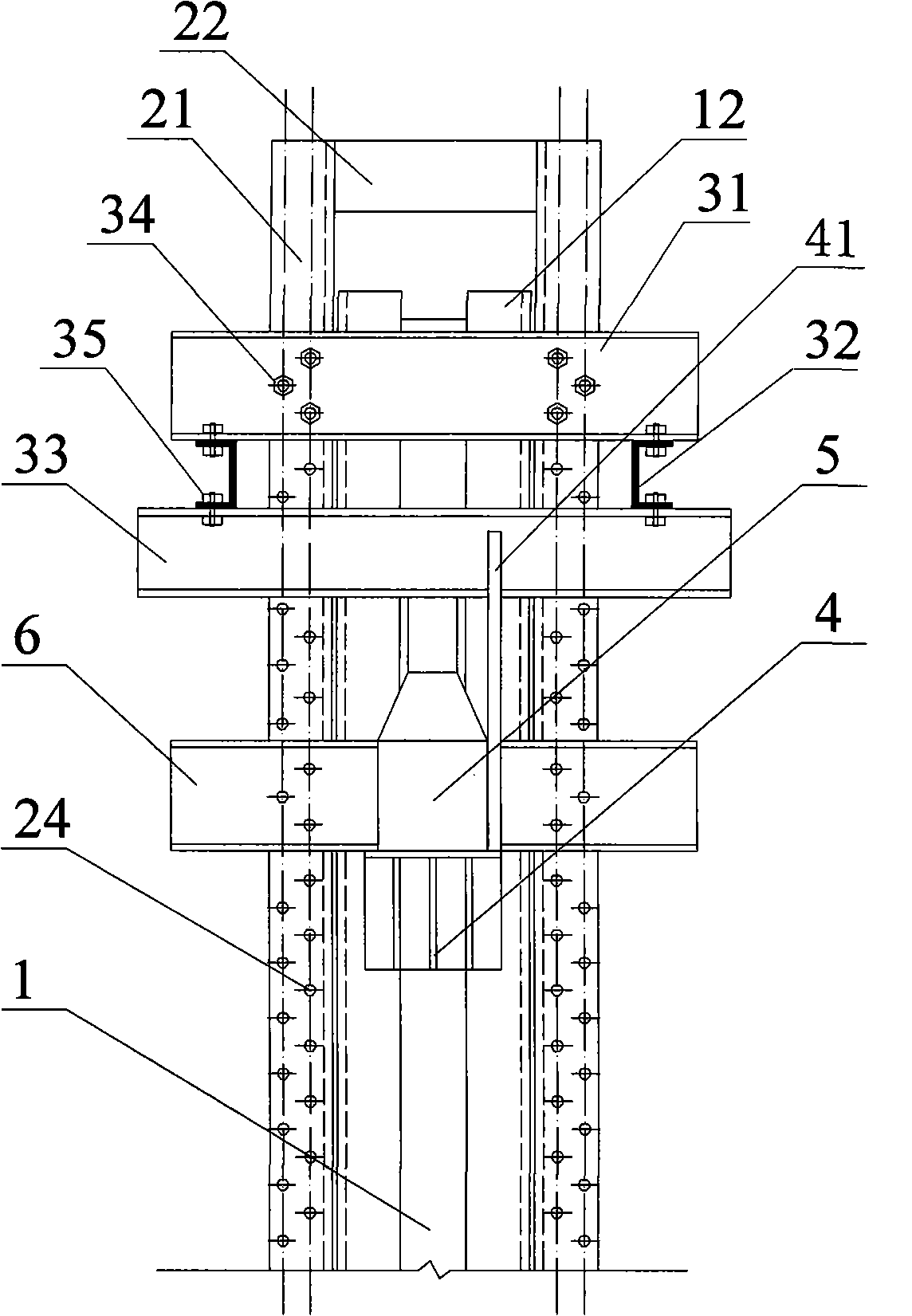

[0028] A factory building hinged with steel roof trusses and concrete columns, the original net height of the factory building is 18.9 meters, and now it is required to increase to 19.95 meters, and the lifting height is 1.05 meters. The factory building is a concrete column bent frame structure with a distance of 6 meters between the concrete columns and a rectangular cross section of the concrete column. The span of the steel roof truss is 36 meters. The total weight of the roof is 3780 tons. The total length of the factory building is 234 meters and there are two expansion joints. We disconnected at the expansion joints, and divided the workshop into three units to jack up, each unit jacked up 14 roof trusses, and the jacking weight of each jacking point was 45 tons, and each jacking point used two 50-ton screw jack for lifting. The jacking process of each unit is completed in five times. The first, second, third, and fourth jacking heights are all 0.205 meters, and the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com