Method for smelting boron steel directly from pig iron containing boron

A technology of boron pig iron and boron steel, which is applied in the field of iron and steel smelting, can solve the problems of the uniformity of boron yield distribution and the difficulty of maintaining stable steel properties, and achieve the effects of eliminating cumbersome procedures, stable performance, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

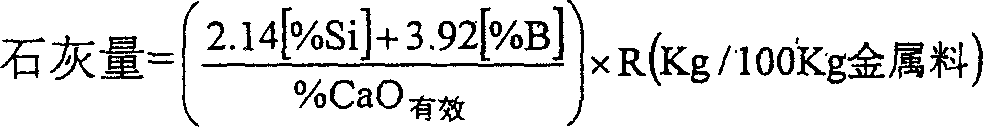

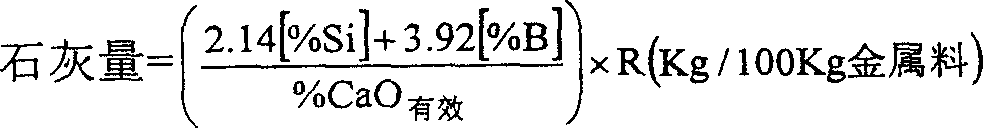

Method used

Image

Examples

example 1

[0016] Example 1: Take 1000g of boron-containing pig iron produced in a blast furnace, add 15g of calcium carbide-based desulfurizer for desulfurization, and obtain pretreated desulfurized boron-containing pig iron. Take 700g of the above-mentioned desulfurized boron-containing pig iron, its weight % content: B: 0.31, Si: 2.15, C: 3.88, P: 0.06, S: 0.05, Mn: 0.09 and 300g of scrap steel, put it into a corundum crucible, and use a medium frequency induction furnace to heat , When the temperature reaches 1400 ℃, power off, continue to maintain the temperature of the molten pool at 1400 ℃, add 140g of slagging agent, including 120g of CaO, 10g of iron oxide scale, and 10g of MgO. Blow oxygen to the liquid surface of the molten pool, the intensity is 2.5Nl / Kg min, the oxygen blowing time is 20min, stop blowing, add manganese ferroalloy 10g, the Mn content is 75-80%, and the tapping temperature is controlled at 1560°C to obtain boron steel product. Sampling and analysis result wei...

example 2

[0017] Example 2: Take 1000g of boron-containing pig iron produced in a blast furnace, add 13g of CaO and 2g of sodium carbonate for desulfurization, and obtain pretreated boron-containing pig iron. Take 600g of the above-mentioned desulfurized boron-containing pig iron, its weight % content: B: 0.45, Si: 2.52, C: 3.53, P: 0.06, S: 0.05, Mn: 0.10 and scrap steel 400g, put it into a corundum crucible, and use a medium frequency induction furnace to heat , When the temperature reaches 1400°C, the power is cut off, and the temperature of the molten pool is maintained at 1400°C, and 150g of slagging agent is added, including 130g of CaO and 20g of iron oxide scale. Then blow oxygen into the molten pool, the intensity is 3.0Nl / Kg·min, the oxygen blowing time is 23min, stop blowing. Finally, 10 g of ferromanganese alloy is added, the Mn content is 75-80%, and the tapping temperature is controlled at 1570° C. to obtain boron steel products. Sampling analysis results weight % content...

example 3

[0018] Example 3: Take 1000g of boron-containing pig iron produced in a blast furnace, add CaO2g and 13g of calcium carbide desulfurizer for desulfurization, and obtain pretreated boron-containing pig iron. Take 500g of the above-mentioned desulfurized boron-containing pig iron, whose weight % content is: B: 0.59, Si: 2.70, C: 3.10, P: 0.06, S: 0.05, Mn: 0.12, 400g of scrap steel and 100g of iron concentrate, and put them into the corundum crucible , using medium frequency induction furnace heating, when the temperature reaches 1400 ℃, cut off the power, and maintain the temperature of the molten pool at 1400 ℃, add 150g of slagging agent, including 130g of CaO, 20g of iron oxide scale. Then blow oxygen to the molten pool, its strength is 3.5Nl / Kg·min, the oxygen blowing time is 25min, stop blowing. Finally, 10 g of ferromanganese alloy containing Mn75-80% is added, and the tapping temperature is controlled at 1580° C. to obtain boron steel products. Sampling and analysis res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com