Numerical-control gravure double-head finish-turning machine

A technology of fine turning and double guide rails, which is applied in the direction of turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of affecting the concentricity of the two turnings of the inner hole of the steel pipe, increasing the time for upper and lower plates, and low processing efficiency, etc., to achieve The effect of good processing quality, improving processing efficiency and reducing workers' skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

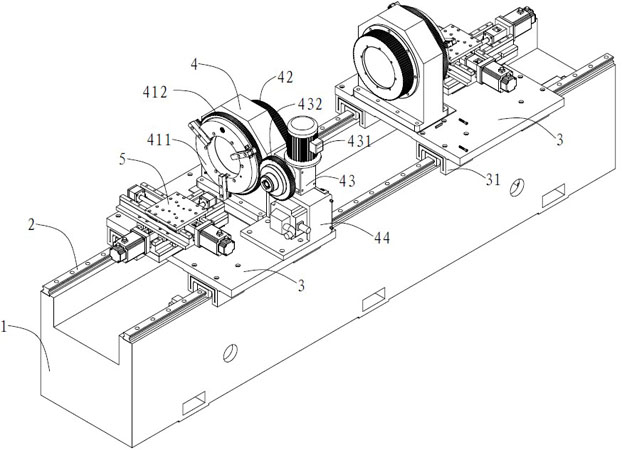

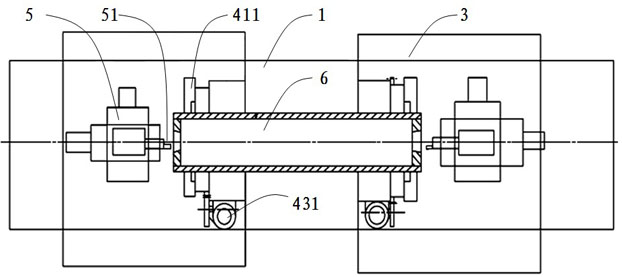

[0016] see Figure 1-5 As shown, the present invention relates to a CNC gravure double-head finishing machine. There are double guide rail slides (3) on the linear guide rail (2) of the bed worktable (1), and the main shaft on the double guide rail slide (3) The box tailstock (4) is installed in sequence with the double-coordinate cross slide (5), the double-rail slide (3) is connected with the linear guide (2) through the linear guide pair (31), and the headstock tailstock (4) is installed On the opposite inner side of the double guide rail slide table (3), the double coordinate cross slide table (5) is installed on the relative outer side of the double guide rail slide table (3).

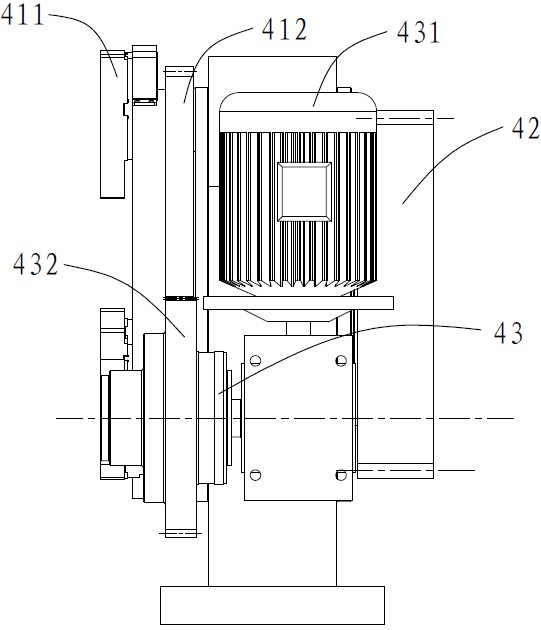

[0017] The CNC gravure double-head finishing machine disclosed by the present invention has a custom-made chuck (41) on the outside of the headstock tailstock (4), a timing pulley (42) on the inside, an electromagnetic clutch (43) at the front end and a custom-made chuck Disk (41) is connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com