Rare earth-magnesium-transition metal base hydrogen storage metal and preparation method thereof

A technology of transition metals and hydrogen storage alloys, applied in the field of hydrogen storage materials, can solve the problems of slow hydrogen absorption and desorption, high hydrogen absorption and desorption temperature, and lack of magnesium content, etc., to achieve control of volatilization loss, high hydrogen storage capacity, and reduced volatilization loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

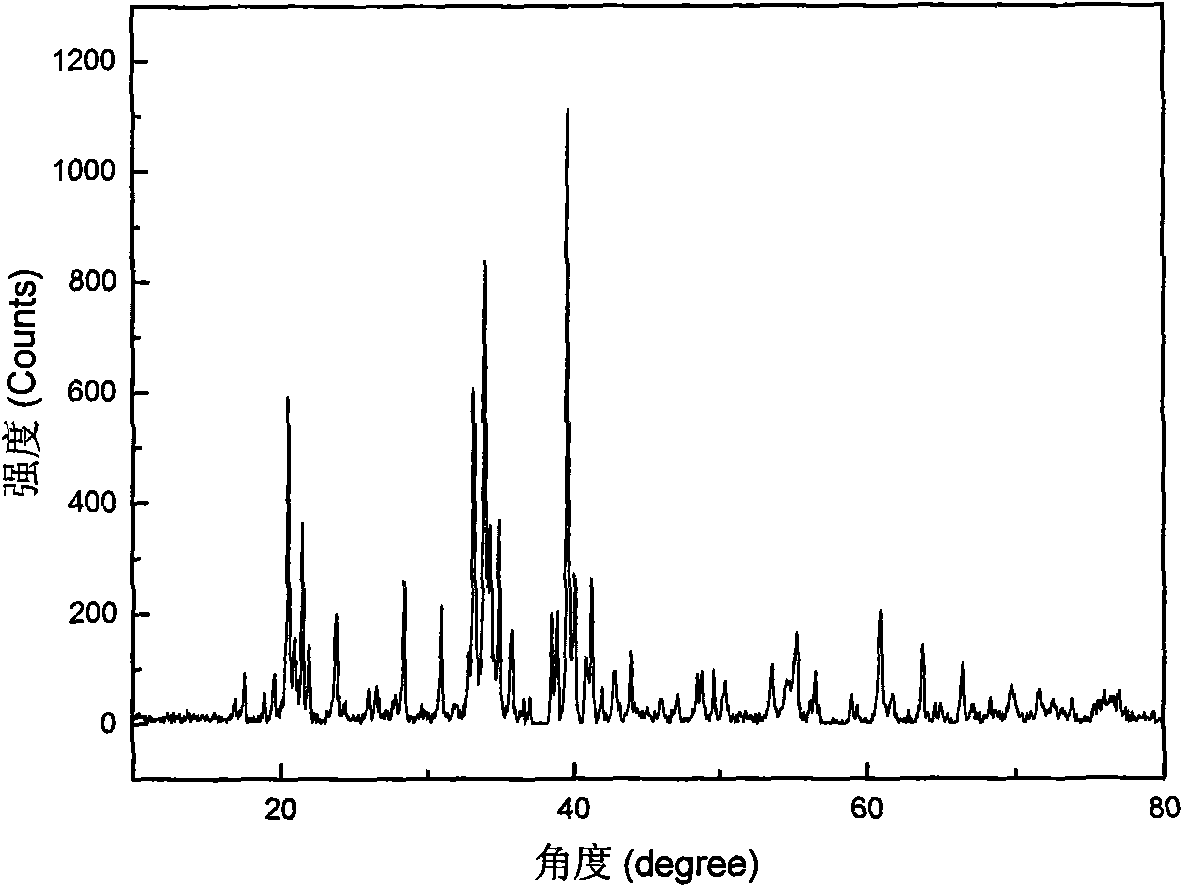

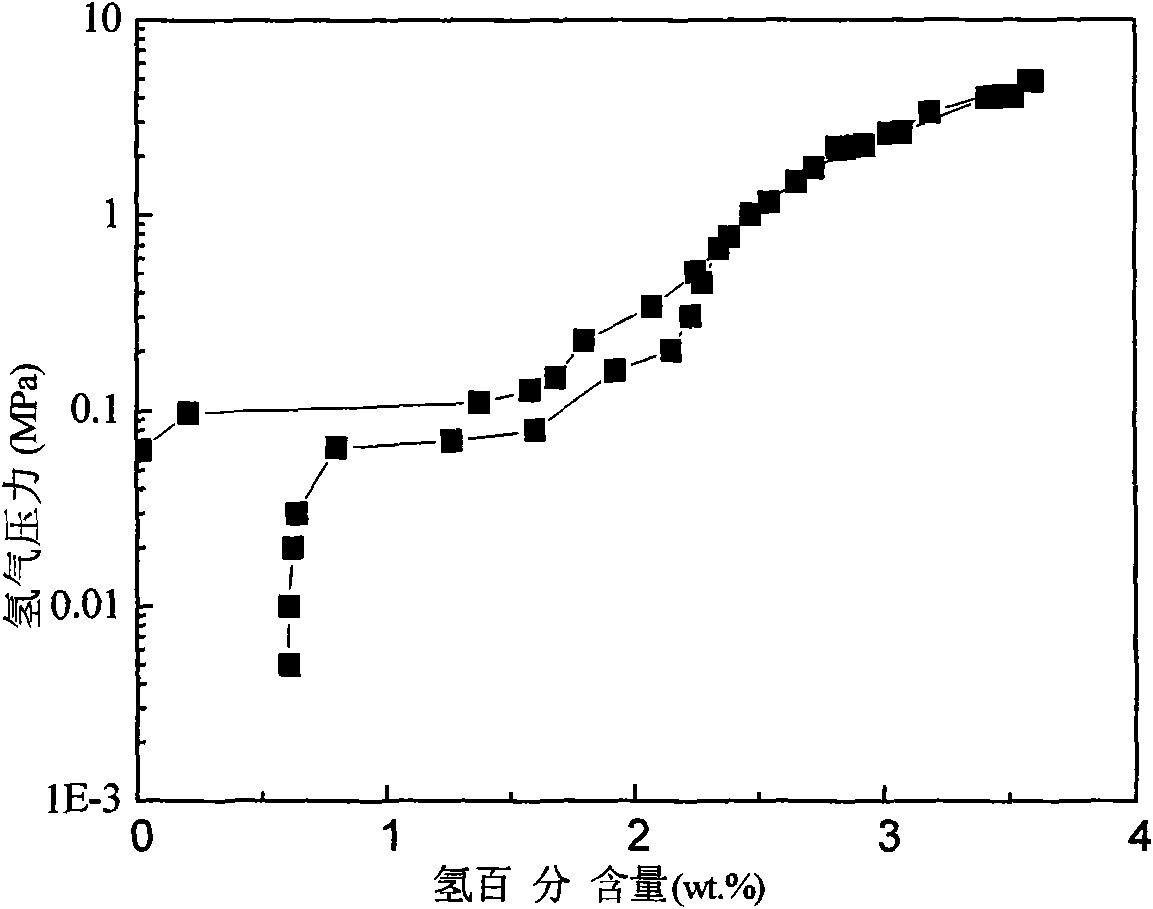

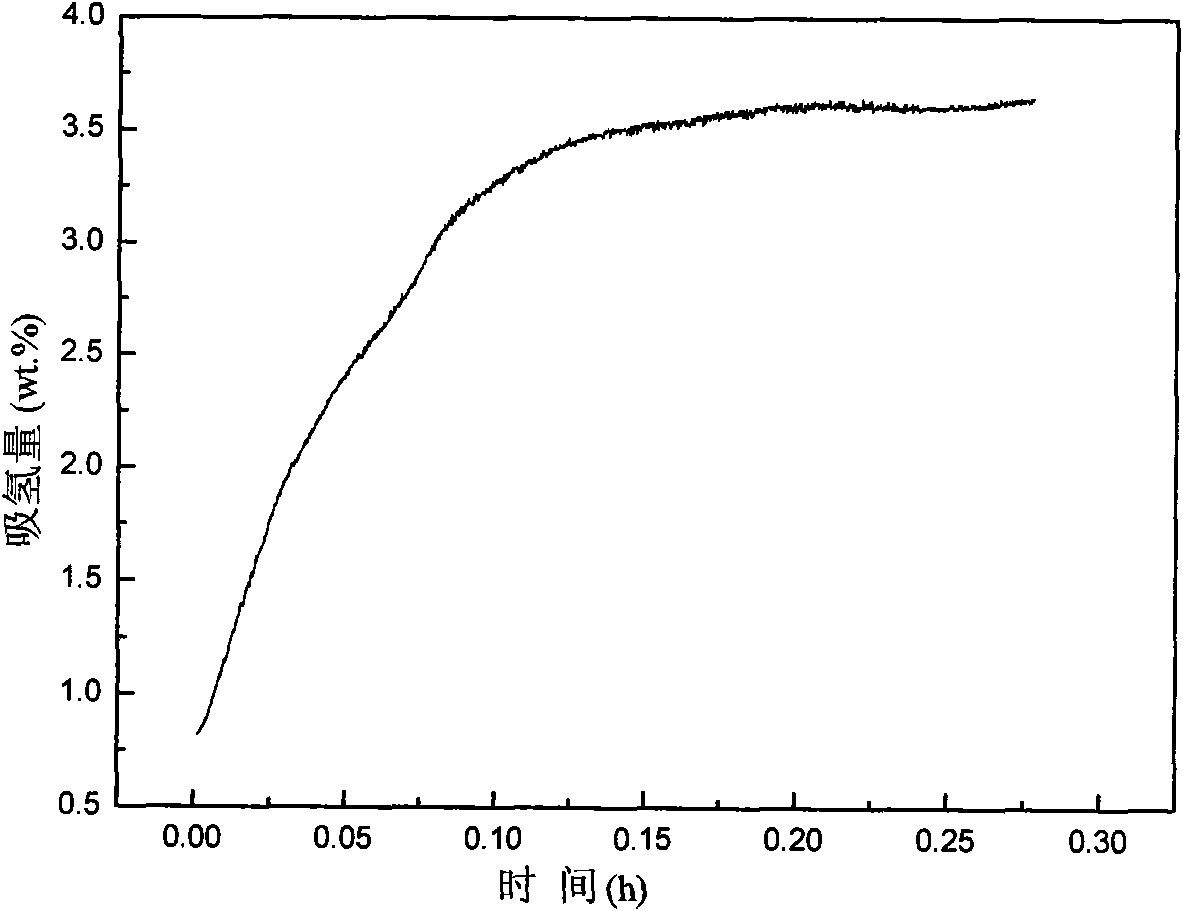

[0027] The ingredients are formulated according to the alloy chemical composition formula LaMg2Cu1.5Ni0.5, Mg is made of LaMg3 master alloy as raw material, other elements are made of simple metal, and the purity is above 99.9%. Use a domestic 10Kg vacuum induction furnace for melting, evacuate to 10-2Pa, fill with argon to a pressure of 0.06MPa, adjust power and melting temperature to melt all raw materials, and add Mg2Ni master alloy by secondary feeding. Keep warm at about 500°C for 5 minutes. After smelting, pour the molten metal into a copper mold with cooling water, and leave the furnace after cooling to 40°C. Then the alloy ingot is annealed under the protection of an inert gas, the treatment temperature is 350° C., and the temperature is kept for 12 hours. After annealing, inductively coupled plasma emission spectroscopy (ICP) was used for elemental analysis, and the results are shown in Table 1. Carry out X-ray powder diffraction analysis (XRD) to sample, the result ...

Embodiment 2

[0029] The chemical composition formula is LaMg 2 Fe 0.5 Ni 1.5 , where Mg is MgNi 2 The master alloy is used as the raw material, the purity of other elemental raw materials is the same as in Example 1, and the melting method of the alloy is the same as in Example 1. The annealing method after the sample was taken out of the furnace was the same as in Example 1, the annealing temperature was 400° C., and the annealing time was 8 hours. The ICP analysis results of the alloy and the hydrogen absorption capacity of the test are shown in Table 1, and the X-ray diffraction patterns are shown in Table 1. Figure 4 .

Embodiment 3

[0031] The chemical composition formula is LaMgNi 1.0 Cu 1.0 , batching and smelting method are with embodiment 1. The annealing temperature is 430° C., and the annealing holding time is 5 hours. The ICP analysis results and hydrogen absorption of the alloy are shown in Table 1, and the X-ray diffraction patterns are shown in Table 1. Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com