Cosmetic sponge, process for producing elastic polyurethane object, and applicator for cosmetic preparation

A Polyurethane Elastomer, Polyurethane Elasticity Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Raw materials used in the production of the polyurethane elastomer (cosmetic sponge) are as follows.

[0117] ・F-151 (polyester-based polyurethane manufactured by Fushimi Pharmaceutical Co., Ltd., solid content 30%)

[0118] 50 parts by mass

[0119] ・T-191 (Fushimi Pharmaceutical Co., Ltd. polyether polyurethane, solid content 30%)

[0120] 50 parts by mass

[0121] 15 parts by mass of dimethylformamide

[0122] ・SORGEN 30 (Sorbitan Sesquioleate HLB value 3.7 manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.)

[0123] 4 parts by mass

[0124] · 400 parts by mass of neutral anhydrous Glauber's salt B (sold by Fushimi Pharmaceutical Co., Ltd.)

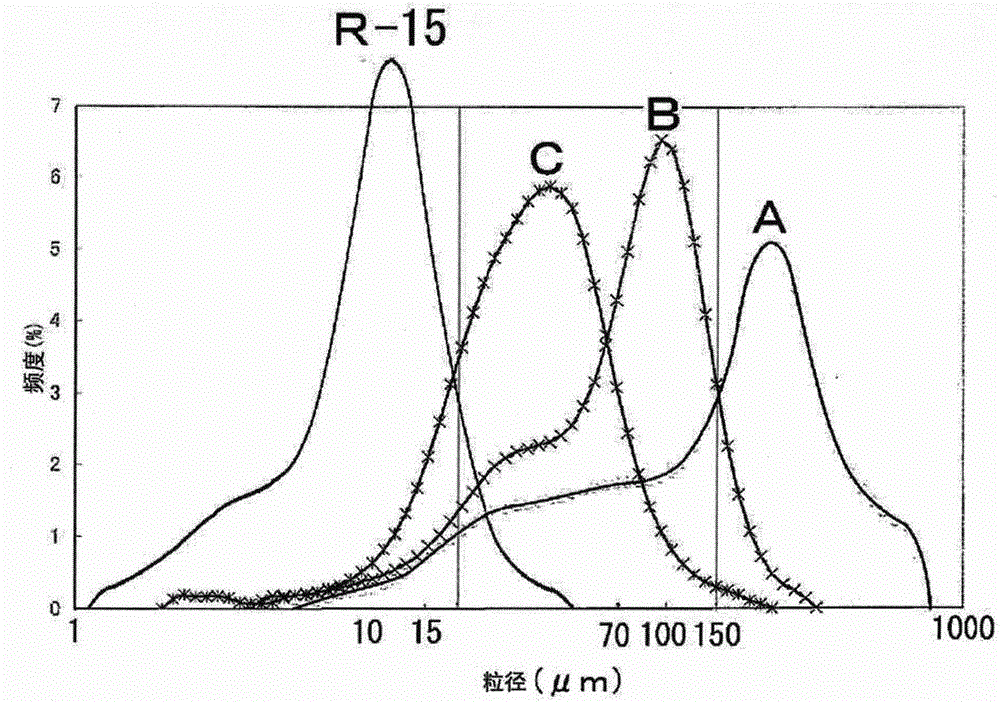

[0125] To illustrate, neutral anhydrous Glauber's salt B has Table 1 and figure 1 Particle size distribution shown. The particle size distribution of the neutral anhydrous Glauber's salt used in other embodiments or comparative examples is also shown in Table 1 and figure 1 . In the following d...

Embodiment 2

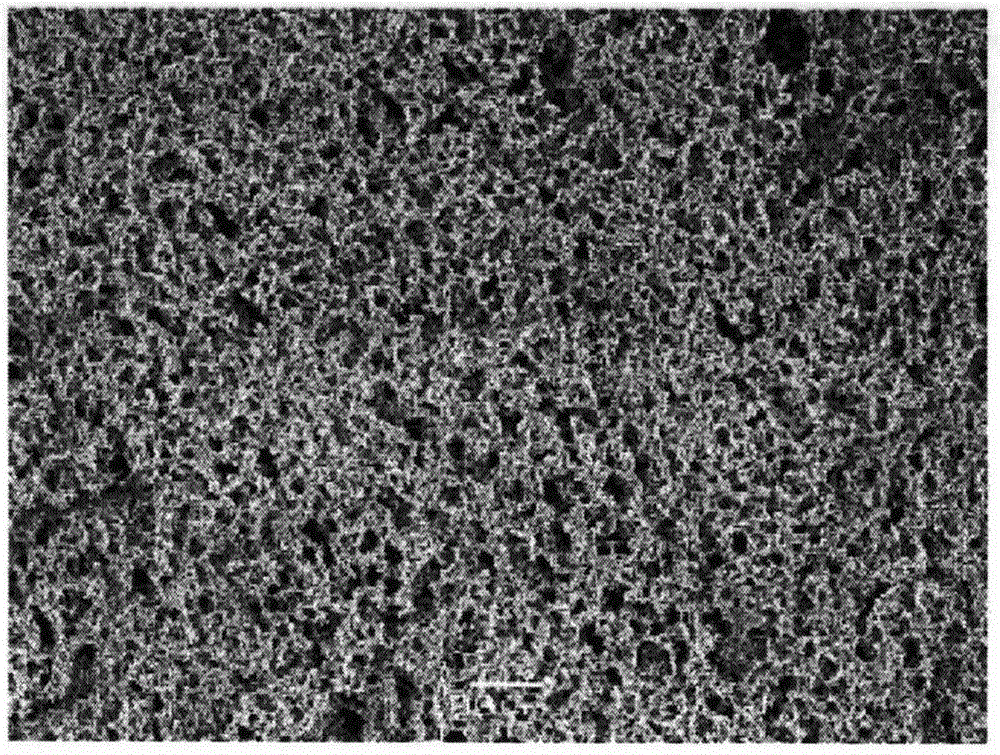

[0129] Replace Glauber's salt B with Table 1, figure 1 Except that Glauber's salt C (available from Fushimi Pharmaceutical Co., Ltd.) with the particle size distribution shown was used, a polyurethane elastomer was obtained in the same manner as in Example 1, and the pore diameter (maximum diameter) was measured in the same manner as in Example 1. The number of pores above 15 μm and below 75 μm, the number of pores above 75 μm and below 150 μm, and the number of pores exceeding 150 μm were measured for apparent density, tensile strength, elongation, hardness, absorption depth, extension area and ethanol permeability. over time. The scanning electron microscope photographs are shown in image 3 , and record each measurement result in Table 2. Such as image 3 As shown, the obtained cosmetic sponge has a three-dimensional membrane structure.

Embodiment 3

[0152] The skin layer on the surface side and the back side of the polyurethane elastomer obtained in Example 1 was removed by a roller cutter to obtain a sponge body with a thickness of 8 mm. This sponge was cut with a Thomson knife, and ground with a whetstone that rotated the section to obtain a cosmetic applicator (cosmetic puff) with a thickness of 8 mm and a diameter of 60 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com