Twisted-type submerged-arc flux-cored wire with high efficiency and crack resistance and preparation method thereof

A flux-cored wire and crack resistance technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high energy consumption in the repair process, hot cracks in the surfacing layer, and high production costs, and achieve abnormal weld structure and Small component segregation, low welding energy consumption, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

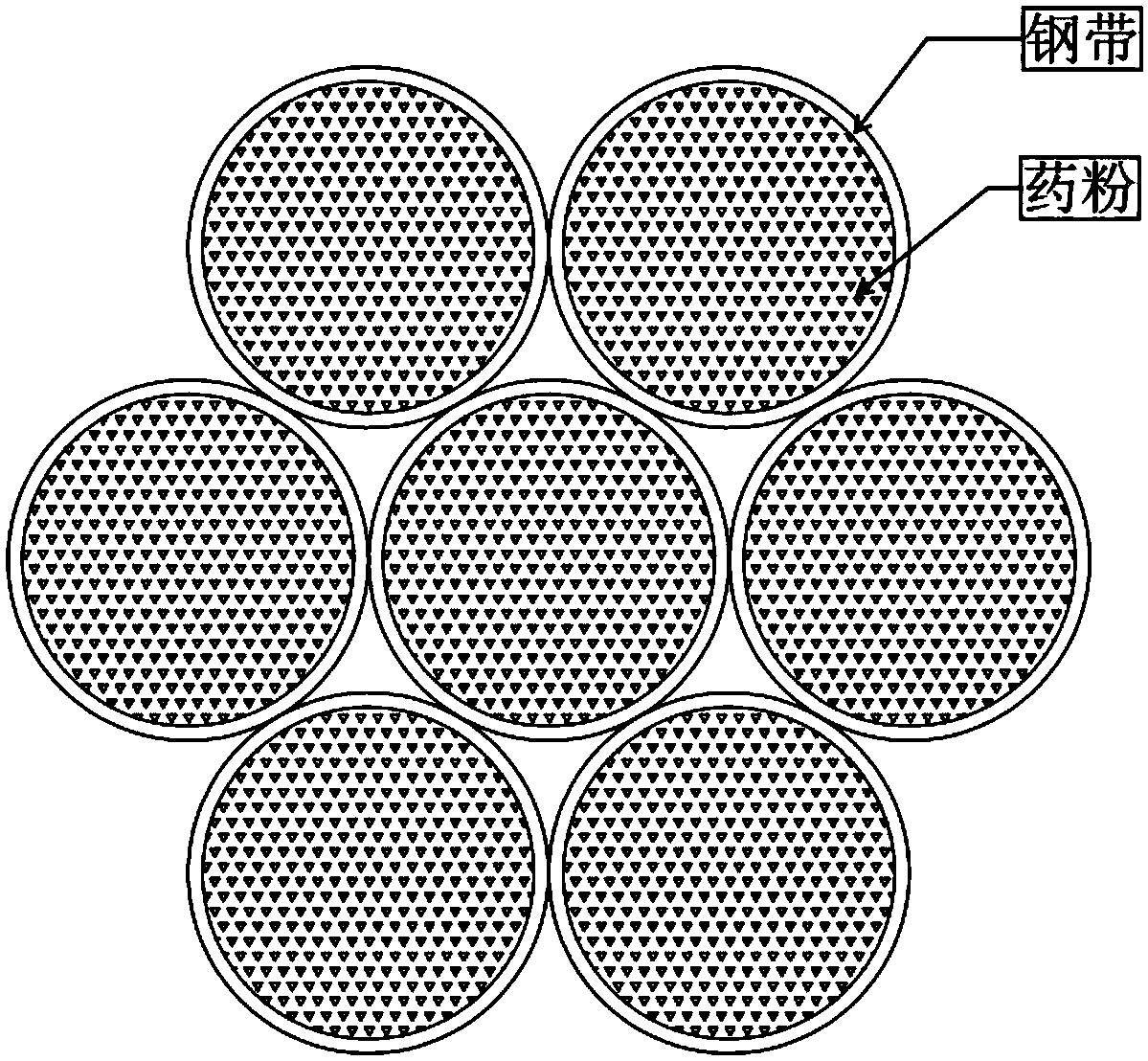

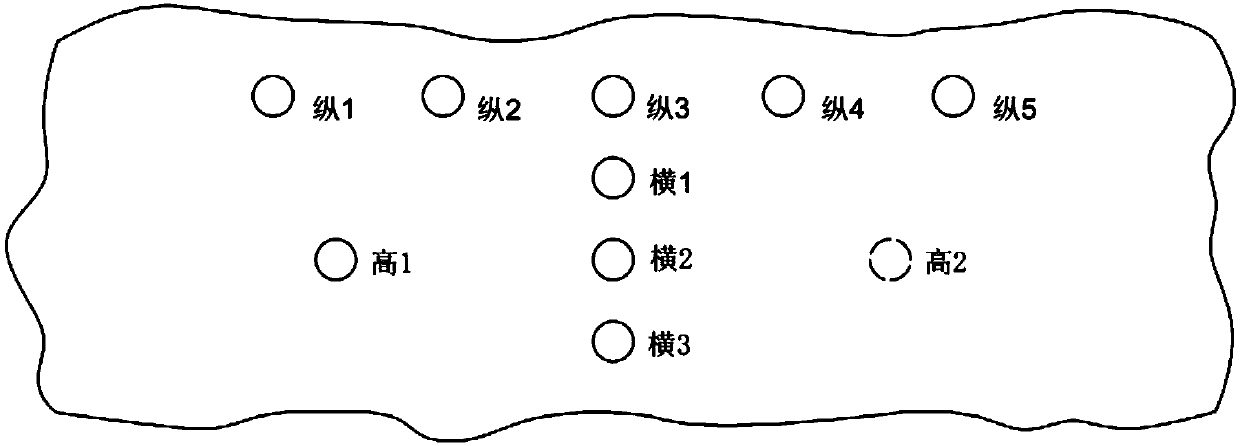

[0026] A stranded submerged arc flux-cored welding wire with high efficiency and crack resistance. The raw materials of the flux core powder are divided into: 28 parts of low-carbon ferrochromium, 45 parts of pig iron, 9 parts of electrolytic manganese, and ferromolybdenum. 6.5 parts, 3.5 parts of ferro-tungsten, 1.5 parts of ferro-vanadium, 1 part of carbon powder, 1 part of metal silicon powder, and 0.5 parts of ferroniobium. Fill low-carbon ferrochromium, pig iron, ferrotungsten, ferro-vanadium, and carbon powder into the medium-frequency induction furnace. After melting, add metal silicon powder, ferromolybdenum, ferro-niobium, and electrolytic manganese in turn, and then add 1% of the mass ratio of 3 : 1 silicon-calcium alloy silicon-aluminum-barium-calcium deoxidizer for deoxidation and slag removal, fully fused, mixed evenly for 4 minutes, then sprayed and atomized at 1620°C, passed through a 150-mesh sieve after drying, and obtained drug core powder. According to the b...

Embodiment 2

[0029] A stranded submerged arc flux-cored welding wire with both high efficiency and crack resistance. The raw materials of the flux core powder are divided into: 30 parts of low-carbon ferrochrome, 42 parts of pig iron, 8.5 parts of electrolytic manganese, and ferromolybdenum. 6 parts, 4 parts of ferro-tungsten, 2 parts of ferro-vanadium, 1.6 parts of carbon powder, 1.2 parts of metal silicon powder, and 0.8 parts of ferroniobium. Fill low-carbon ferrochrome, pig iron, ferrotungsten, ferro-vanadium, and carbon powder into the medium-frequency induction furnace. After melting, add metal silicon powder, ferro-molybdenum, ferro-niobium, and electrolytic manganese in sequence, and then add 1.3% of the mass ratio of 3 : 1 silicon-calcium alloy silicon-aluminum-barium-calcium deoxidizer for deoxidation and slag removal, fully fused, mixed evenly for 3 minutes, then sprayed and atomized at 1600°C, passed through a 100-mesh sieve after drying, and obtained drug core powder. Accordin...

Embodiment 3

[0032] A stranded submerged arc flux-cored welding wire with high efficiency and crack resistance. The raw materials of the flux core powder are divided into: 32 parts of low-carbon ferrochromium, 46 parts of pig iron, 9.5 parts of electrolytic manganese, and ferromolybdenum. 7 parts, 4.5 parts of ferro-tungsten, 2.5 parts of ferro-vanadium, 1.2 parts of carbon powder, 1 part of metal silicon powder, and 0.4 parts of ferroniobium. Fill low-carbon ferrochrome, pig iron, ferrotungsten, ferro-vanadium, and carbon powder into the medium-frequency induction furnace. After melting, add metal silicon powder, ferro-molybdenum, ferro-niobium, and electrolytic manganese in turn, and then add 0.6% of the mass ratio of 3 : 1 silicon-calcium alloy silicon-aluminum-barium-calcium deoxidizer for deoxidation and slag removal, fully fused, mixed evenly for 3 minutes, then sprayed and atomized at 1650°C, passed through an 80-mesh sieve after drying, and obtained the drug core powder. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com