Amorphous-nanocrystalline soft magnetic material and preparation method and application thereof, amorphous strip, amorphous-nanocrystalline strip and amorphous-nanocrystalline magnetic sheet

A technology of amorphous nanocrystalline and soft magnetic materials, which is applied in the direction of magnetic materials, inductors/transformers/magnets, magnetic objects, etc., can solve the problems of high process difficulty and high coercive force of iron-based nanocrystalline soft magnetic alloys, and achieve Balance the saturation magnetic induction and coercive force, improve the ability of amorphous formation, and improve the effect of comprehensive magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0076] 1. Ingredients: raw materials with a purity greater than 99% 80 Si 5 B 7 Cu 1 P 4 Zr 2 (NbC) 1 The alloy components are mixed, wherein B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, Nb in the form of niobium-iron alloy, and C in the form of iron-carbon alloy.

[0077] 2. Melting: Put the well-proportioned raw materials into the crucible of the melting furnace, and in an argon atmosphere, use the method of arc melting to melt at 1500°C to obtain an alloy ingot with a uniform composition.

[0078] 3. Manufacturing of amorphous alloy: after the alloy ingot described in step 2 is remelted, the alloy ingot described in step 2 is quenched by a single-roller quenching method, and the cooling rate of quenching is 10 6 °C / s or more, a strip-shaped amorphous alloy is obtained.

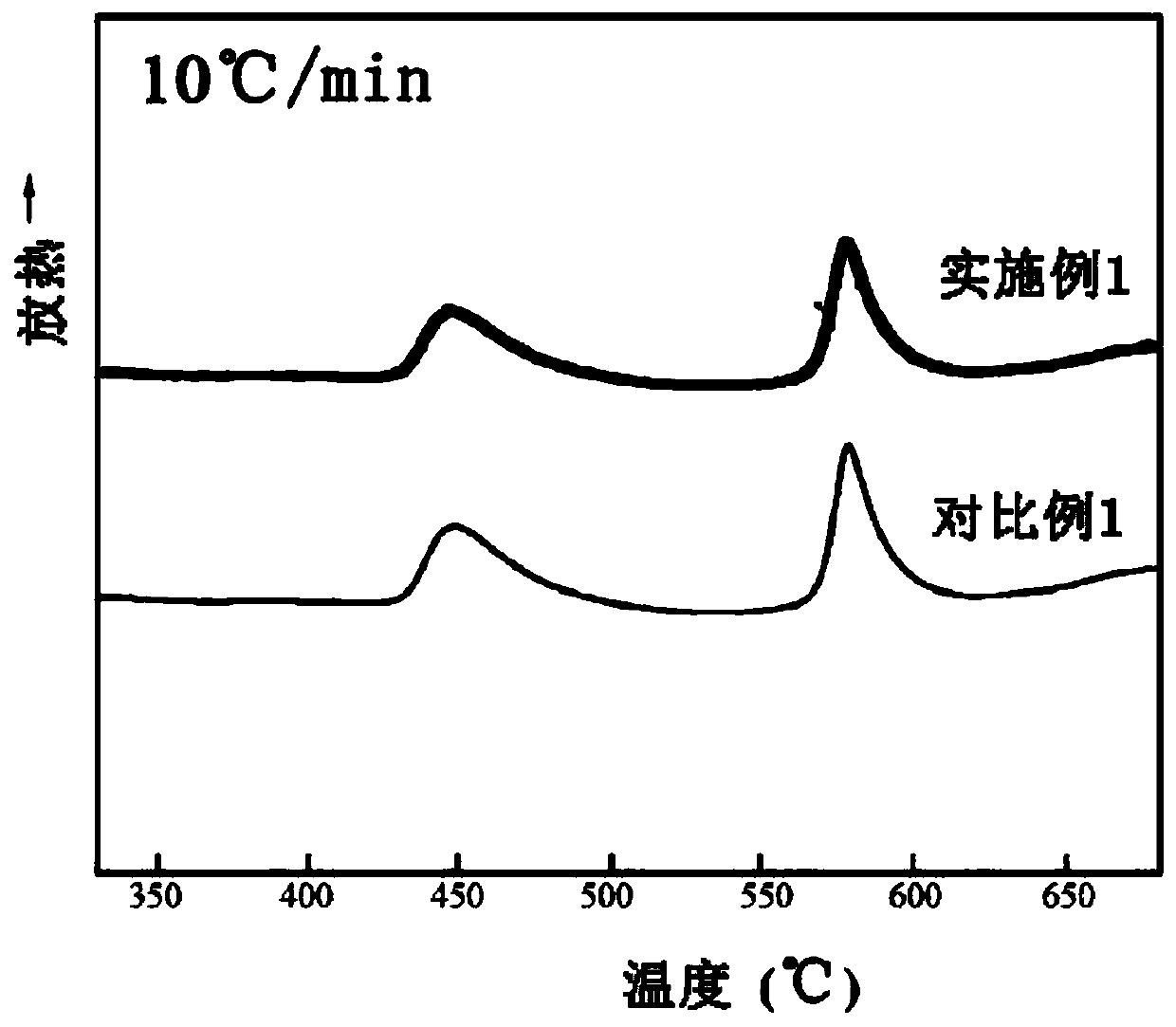

[0079] DSC (Differential Scanning Calorim...

Embodiment 2

[0094] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0095] 1. Ingredients: raw materials with a purity greater than 99% 79 Si 1 B 10 Cu 0.5 P 6 Zr 1 Mo 2 (NbC) 0.5 The alloy components are mixed, wherein B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, Nb in the form of niobium-iron alloy, and C in the form of iron-carbon alloy.

[0096] 2. Melting: Put the raw materials with a good ratio into the crucible of the melting furnace, and use the arc melting method to melt at 1300°C under a vacuum state to obtain an alloy ingot with a uniform composition.

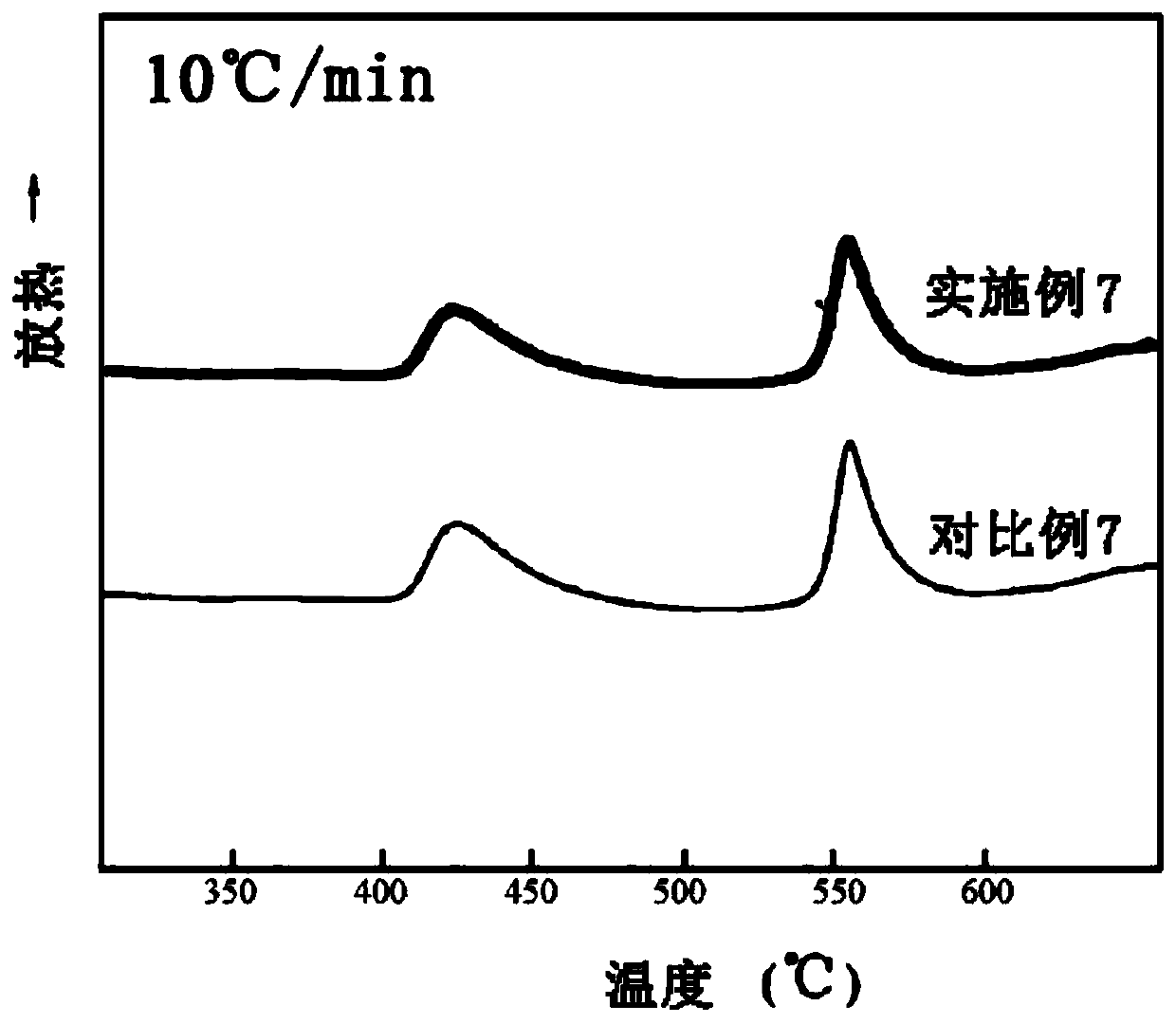

[0097] 3. Manufacturing of amorphous alloy: after the alloy ingot described in step 2 is re-melted, the strip-shaped amorphous alloy is produced by a single-roll quenching method. DSC (Differential Scanning Calorimeter, Differential Scanning Calorimeter) detection is carried out to the prepared amorphous alloy, and the DS...

Embodiment 3

[0108] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0109] 1. Ingredients: raw materials with a purity greater than 99% 79.5 Si 2 B 7 Cu 3 P 4 Ta 1 W 1 Ge 0.5 f 1.5 (VC) 0.5 The alloy components are mixed, wherein B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, V in the form of vanadium-iron alloy, and C in the form of iron-carbon alloy.

[0110] 2. Melting: Put the raw materials with a good ratio into the crucible of the melting furnace, and in a vacuum state, use the medium frequency induction melting method to melt at 1400°C to obtain an alloy ingot with a uniform composition.

[0111] 3. Manufacturing of amorphous alloy: after the alloy ingot described in step 2 is re-melted, the strip-shaped amorphous alloy is produced by a single-roll quenching method. DSC (Differential Scanning Calorimeter, Differential Scanning Calorimeter) detection is carried out to the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com