Nanocrystalline flexible sheet and preparation method and application thereof

A nano-chip and crystal-flexible technology, applied in the field of nano-crystalline flexible sheet and its preparation, can solve the problem that the charging efficiency of MnZn ferrite and NiZn ferrite is not ideal, cannot have high saturation magnetic induction at the same time, and cannot meet the requirements of use. To achieve the effect of promoting Fe enrichment and nucleation, improving the uniformity of the microstructure, and increasing the ability to form amorphous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

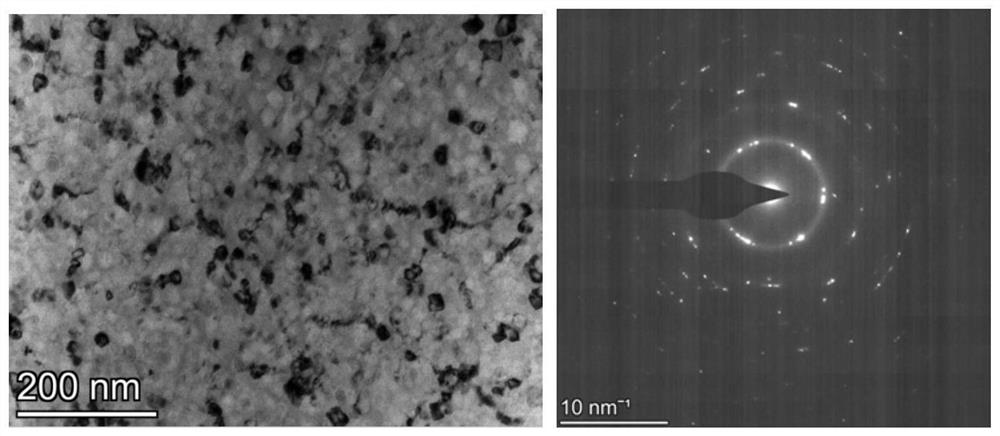

[0054] The present invention also provides a method for preparing a nanocrystalline flexible sheet. In some embodiments, the temperature of the relaxation treatment is 280-380°C, which can be any value in the middle, such as 300°C, 320°C, 350°C , 360°C, etc., the present invention is not limited to this, further, when the relaxation treatment temperature is preferably 300-350°C, the performance of the obtained nanocrystalline flexible sheet is better, and the relaxation treatment temperature is between 300-350°C Any value between, for example, 310°C, 325°C, 335°C, 345°C, etc., which is not limited in the present invention.

[0055] In some embodiments, the relaxation treatment is carried out at a magnetic field strength of 10-800mT. When the magnetic field strength is 500-800mT, the performance of the obtained nanocrystalline flexible sheet is better, and the magnetic field strength is between 500-800mT. Any value, such as 550mT, 600mT, 650mT, 700mT, 750mT, etc., is not limite...

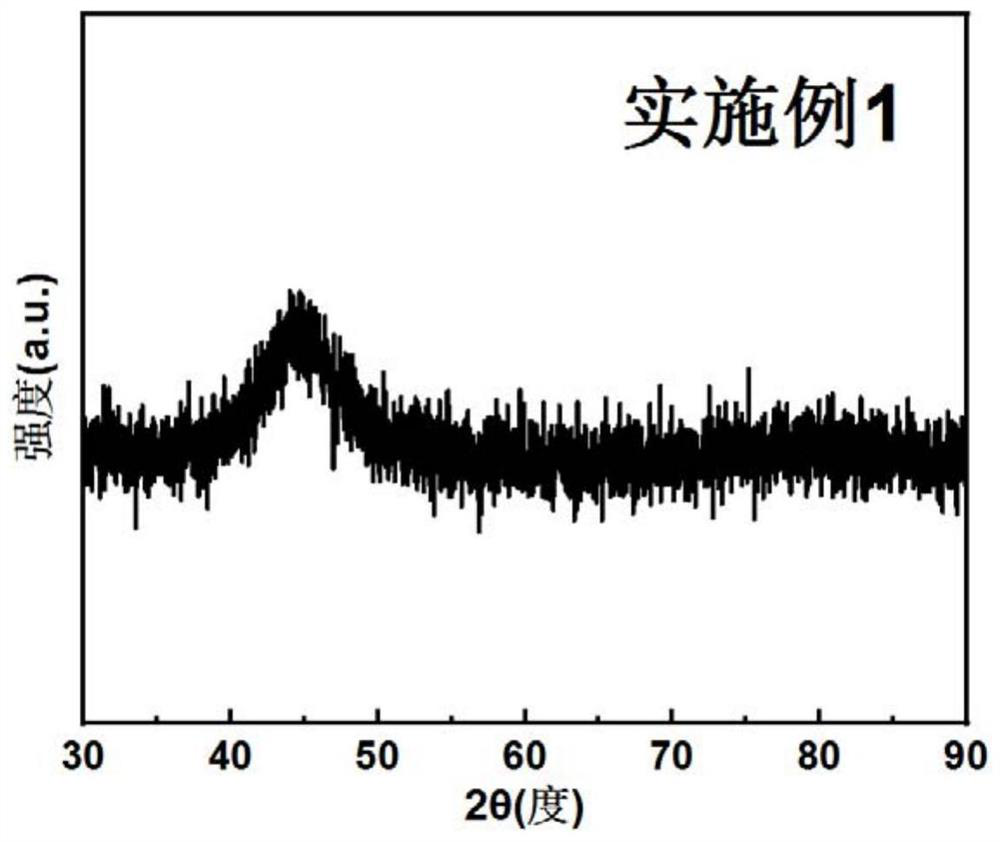

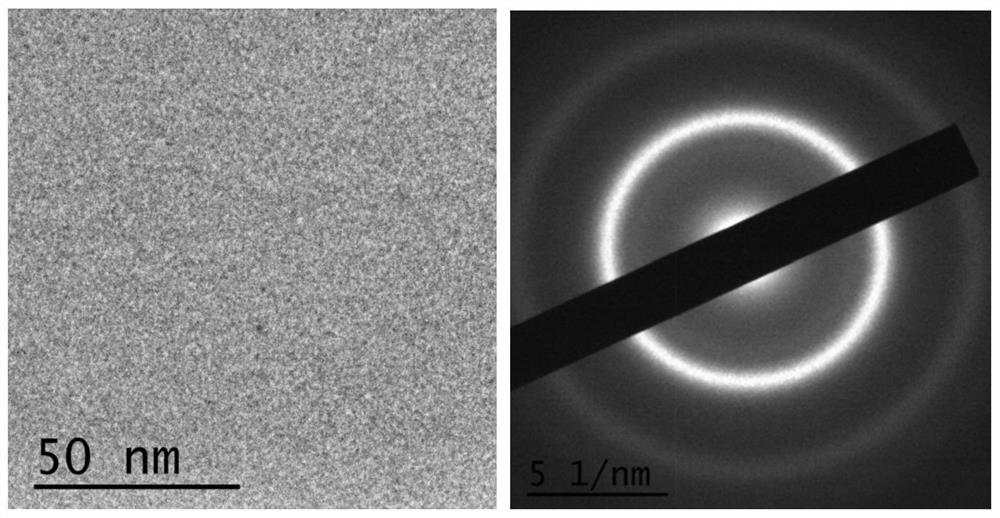

Embodiment 1

[0058] This embodiment provides a nanocrystalline flexible sheet whose components include Fe, Cu, Si, B, Nb, Mo and Y, and the atomic percentages are 76.1at%, 0.9at%, 13.5at%, 7.5at% respectively %, 1.2at%, 0.6at% and 0.2at%, that is, the molecular formula is Fe 76.1 Cu 0.9 Si 13.5 B 7.5 Nb 1.2 Mo 0.6 Y 0.2 .

[0059] The preparation method of the above-mentioned nanocrystalline flexible sheet comprises the following steps:

[0060] (1) Mix iron raw materials, copper raw materials, silicon raw materials, ferroboron alloy ingot raw materials, molybdenum-iron alloy ingot raw materials and yttrium raw materials according to the above percentages, cool at 1320°C for 45 minutes to obtain alloy ingots; then heat the alloy ingots to After the molten liquid is in a liquid state, it is sprayed onto a rotating copper rod through a long and narrow nozzle to obtain a nanocrystalline precursor (the process is rapid quenching and quenching); wherein, the width of the nanocrystalline ...

Embodiment 2

[0064] This embodiment provides a nanocrystalline flexible sheet whose components include Fe, Cu, Si, B, Nb, Mo and Ho, and the atomic percentages are 76.4at%, 0.6at%, 13at%, 8at%, 1.2at%, 0.5at% and 0.1at%, that is, the molecular formula is Fe 76.4 Cu 0.6 Si 13 B 8 Nb 1.2 Mo 0.5 Ho 0.1 .

[0065] The preparation method of the above-mentioned nanocrystalline flexible sheet is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com