Watermelon jam and making method thereof

A production method, the technology of watermelon sauce, applied in the direction of food preparation, application, food science, etc., can solve the problems of single nutritional components, short storage time, waste of resources, etc., achieve rich nutrition, moderate sugar content, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

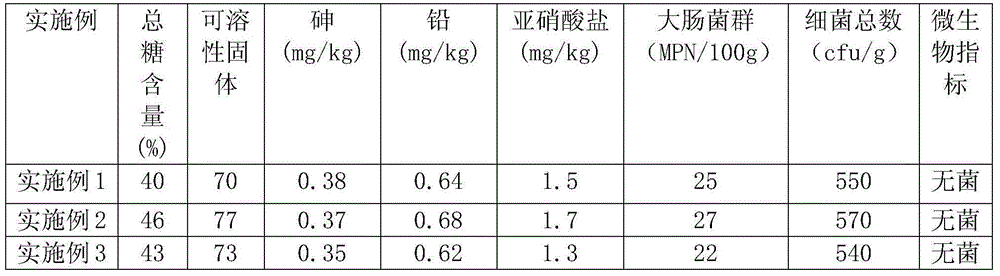

Examples

Embodiment 1

[0025] A kind of preparation method of watermelon sauce, comprises the following steps:

[0026] A. Weigh raw materials by weight: 250 parts of watermelon rind, 100 parts of watermelon flesh, 60 parts of soybean, 200 parts of sesame, 20 parts of hemp, 10 parts of pepper, 25 parts of vegetable oil, 2 parts of table salt, 5 parts of minced ginger, garlic 5 parts of powder, 5 parts of brown sugar, 0.5 parts of citric acid and 100 parts of water.

[0027] B. Pretreatment of soybeans, sesame, and hemp raw materials. Make hemp and sesame into powder and fry them for later use; cook or steam the soybeans, then dry the surface moisture, add brown sugar and stir to mix evenly Carry out fermentation, the normal temperature fermentation time is 20 days, then dry or dry for standby;

[0028] C. Pretreatment of watermelon raw materials: take fresh watermelon, remove the green hard skin and red scoop of the watermelon rind, wash the watermelon rind and cut it into slices, then dry it, and ...

Embodiment 2

[0035] A kind of preparation method of watermelon sauce, comprises the following steps:

[0036] A. Weigh raw materials by weight: 350 parts of watermelon rind, 200 parts of watermelon flesh, 100 parts of soybean, 50 parts of sesame, 50 parts of hemp, 25 parts of pepper, 50 parts of vegetable oil, 8 parts of salt, 15 parts of minced ginger, garlic 15 parts of powder, 15 parts of brown sugar, 4 parts of citric acid and 200 parts of water.

[0037] B. Pretreatment of soybeans, sesame, and hemp raw materials. Make hemp and sesame into powder and fry them for later use; cook or steam the soybeans, then dry the surface moisture, add brown sugar and stir to mix evenly Carry out fermentation, and the normal temperature fermentation time is 25 days, then dry or dry for standby;

[0038] C. Pretreatment of watermelon raw materials: take fresh watermelon, remove the green hard skin and red scoop of the watermelon rind, wash the watermelon rind and cut it into slices, then dry it, and t...

Embodiment 3

[0045] A kind of preparation method of watermelon sauce, comprises the following steps:

[0046] A. Weigh raw materials by weight: 300 parts of watermelon rind, 150 parts of watermelon flesh, 90 parts of soybean, 38 parts of sesame, 40 parts of hemp, 18 parts of pepper, 40 parts of vegetable oil, 5 parts of table salt, 10 parts of minced ginger, garlic 10 parts of powder, 12 parts of brown sugar, 2 parts of citric acid and 160 parts of water.

[0047] B. Pretreatment of soybeans, sesame, and hemp raw materials, make hemp and sesame into powder and fry them for later use; cook or steam the soybeans, then dry the surface moisture, add brown sugar and stir to mix evenly Carry out fermentation, the normal temperature fermentation time is 23 days, then dry or dry for standby;

[0048] C. Pretreatment of watermelon raw materials: take fresh watermelon, remove the green hard skin and red scoop of the watermelon rind, wash the watermelon rind and cut it into slices, then dry it, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com